Page 4

For technical questions, please call 1-800-444-3353.

Item 98580

Sa

FE

ty

Op

ER

ati

O

n

m

aint

Enanc

E

SE

tup

Service

1.

Tool service must be performed only

by qualified repair personnel.

2.

When servicing a tool, use only identical

replacement parts. use only authorized parts.

3.

use only the lubricants supplied with the

tool or specified by the manufacturer.

air Source

1.

never connect to an air source that is

capable of exceeding 200 psi.

Over pressurizing the tool may cause

bursting, abnormal operation, breakage

of the tool or serious injury to persons.

Use only clean, dry, regulated compressed air at the

rated pressure or within the rated pressure range as

marked on the tool. Always verify prior to using the

tool that the air source has been adjusted to the rated

air pressure or within the rated air-pressure range.

2.

Never use oxygen, carbon dioxide, combustible

gases or any bottled gas as an air source

for the tool.

Such gases are capable of

explosion and serious injury to persons.

SaVE thESE inStRuctiOnS.

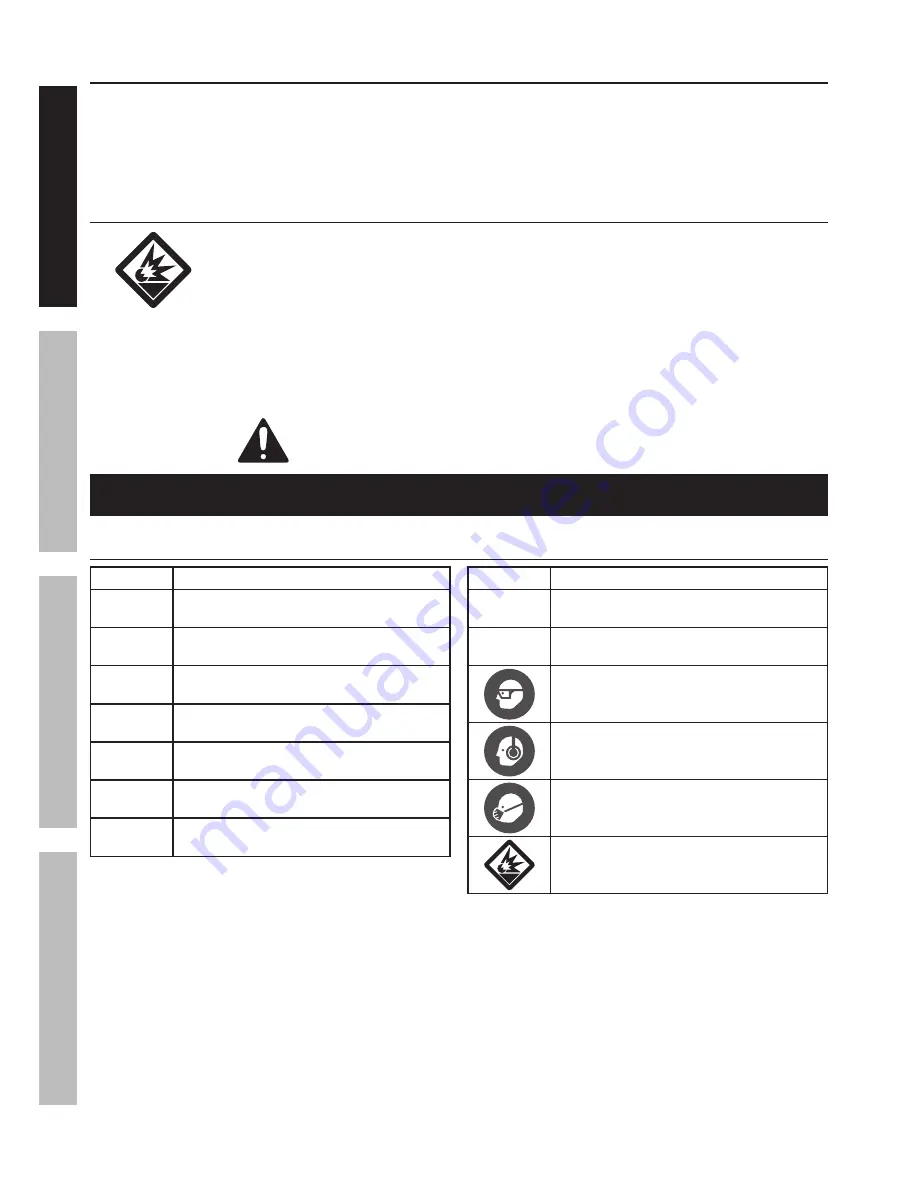

Symbols and Specific Safety instructions

Symbol Definitions

Symbol

property or statement

n

o

No-load speed

.../min

Revolutions or reciprocation per minute

pSi

Pounds per square inch of pressure

ft-lb

Foot-pounds of torque

Bpm

Blows per minute

cFm

Cubic Feet per Minute flow

ScFm

Cubic Feet per Minute flow

at standard conditions

Symbol

property or statement

npt

National pipe thread, tapered

npS

National pipe thread, straight

WARNING marking

concerning Risk of Eye Injury.

Wear ANSI-approved eye protection.

WARNING marking concerning Risk of

Hearing Loss. Wear hearing protection.

WARNING marking concerning

Risk of Respiratory Injury. Wear

NIOSH-approved dust mask/respirator.

WARNING marking concerning

Risk of Explosion.