SKU 99637

For technical questions, please call 1-800-444-3353.

Page 10

FIGURE C

(MAGAZINE OPENED)

MAGAZINE

LATCH

(63)

MAGAZINE

(73)

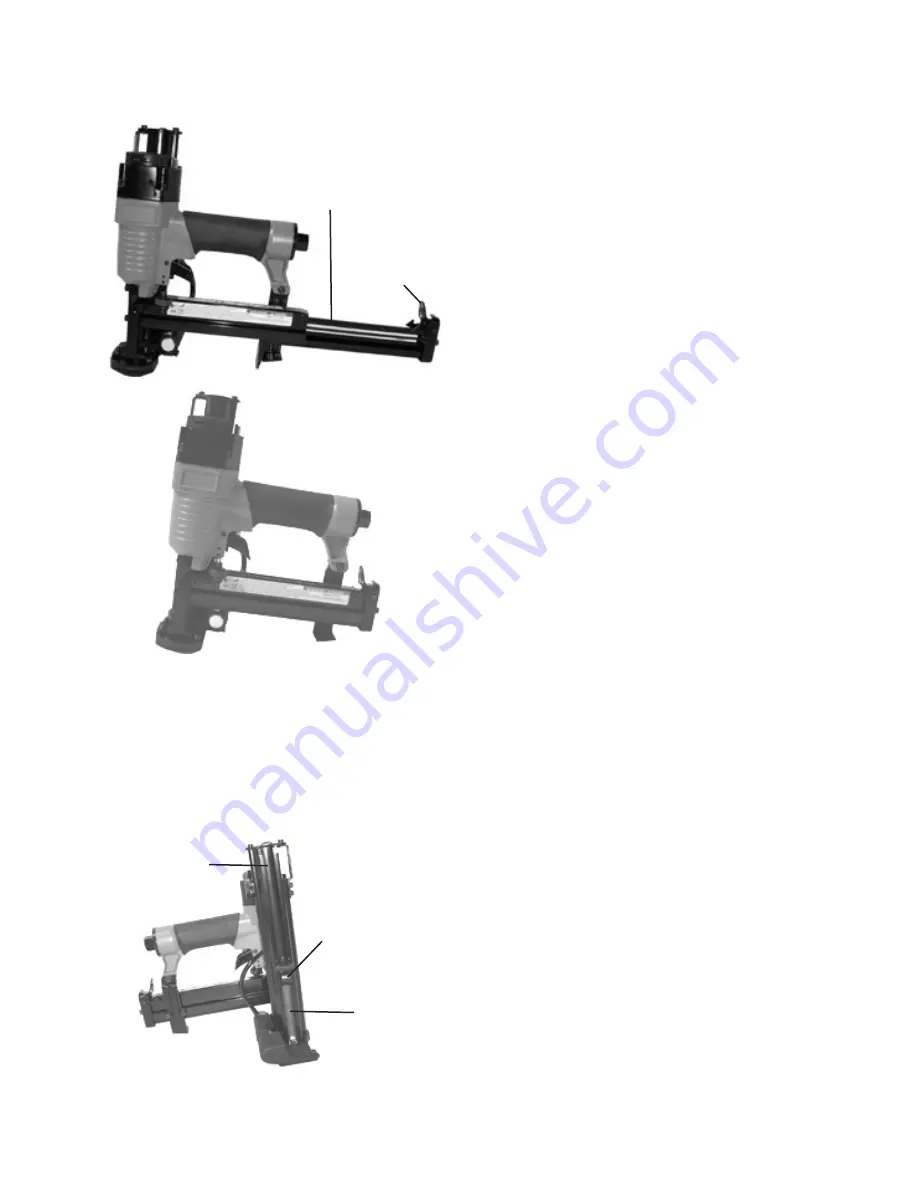

4. To load plastic caps into the Cap

Canister (105), insert the plastic

caps into the Cap Canister. Turn the

Canister Latch (104) to apply pres-

sure on the caps. Then remove the

cap holder line from the plastic caps.

(See Figure E.)

5. To test the single sequential safety

trip mechanism of the Stapler:

• WARNING: Even though the Sta-

pler should be empty during this

procedure, ALWAYS point the Sta-

pler at a piece of scrap wood when

testing.

• Make sure the Stapler is discon-

nected from its air supply.

• Completely empty the Stapler of

staples and plastic caps.

• The Stapler should not fire if the

Bottom Plate (95) is not depressed

against the scrap wood.

• Make sure the Trigger (39) moves

freely, without sticking.

• Connect the air supply to the Sta-

pler. Set the compressor’s regula-

tor at the recommended 70 to 90

operating pressure (PSI). Do not

exceed the maximum 90 PSI.

• Test the Stapler by depressing the

Bottom Plate (95) against the scrap

wood without pulling the Trigger

(39).

The tool must not cycle

(fire).

If it cycles (fires), stop im-

mediately and have it repaired by a

qualified service technician.

• Hold the Stapler away or off the

scrap wood. The Bottom Plate (95)

should return to its original position.

Squeeze the Trigger (39).

The tool

should not cycle (fire).

If the tool

cycles (fires), stop immediately and

have it repaired by a qualified ser-

vice technician.

• Depress the Bottom Plate (95)

against the scrap wood and

squeeze the Trigger (39).

The tool

must cycle (fire) only once.

Re-

lease the Trigger and squeeze it

again.

The tool must cycle (fire)

FIGURE D

(MAGAZINE CLOSED)

FIGURE E

PLASTIC

CAPS

(NOT INCLUDED)

CAP

CANISTER

(105)

CANISTER

LATCH

(104)

REV 08k