C E N T R A L S T A T E S M A N U F A C T U R I N G , I N C .

E f f e c t i v e 0 1 / 2 0 2 1 • I n f o r m a t i o n s u b j e c t t o c h a n g e

55

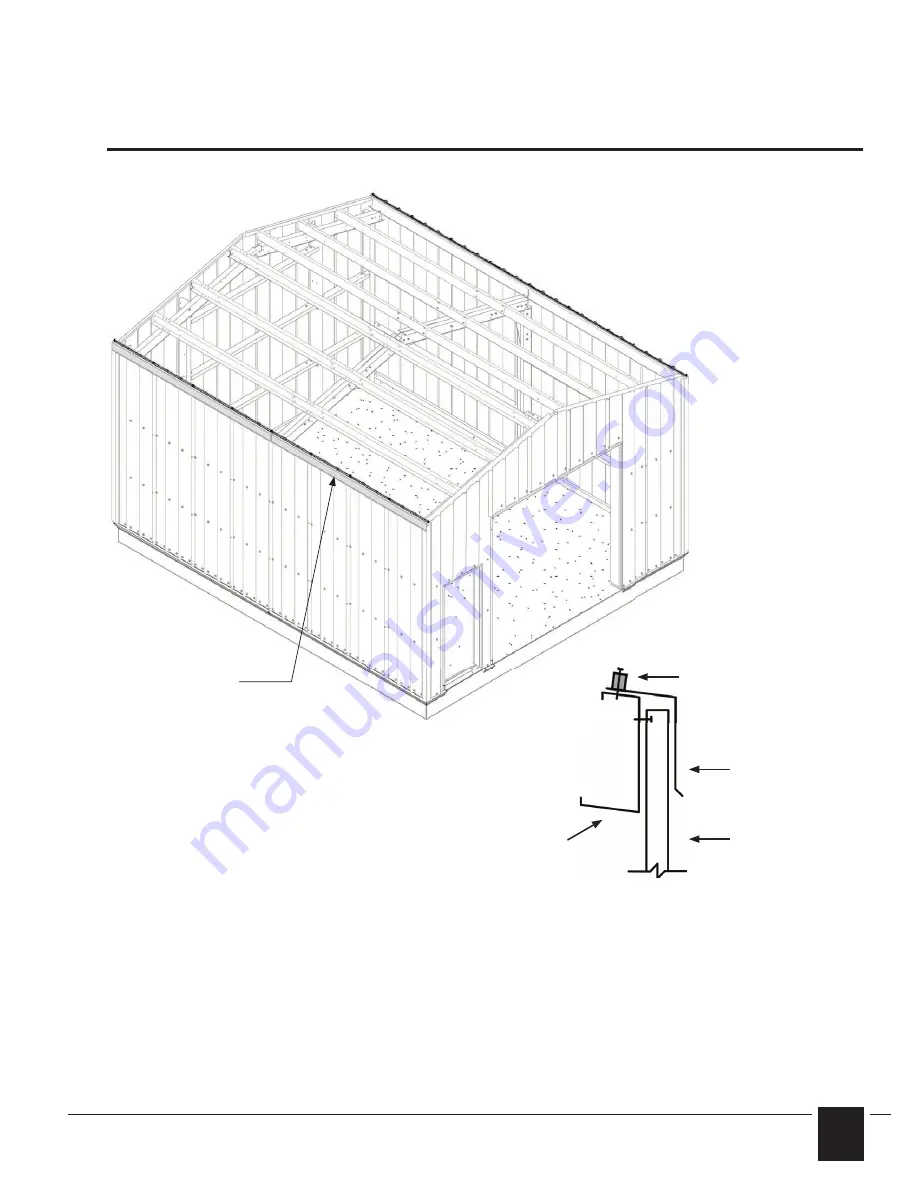

1. Place ACC50 on top of TRIM14 before installing. Line up rib profi le of closure with wall panel rib profi le.

Place on edge of top leg of trim.

2. Install TRIM14 above the eavestrut (PURLIN30) as shown above using FAST12. Use only enough screws to

temporarily hold in place. These screws will be removed when installing roof panels.

3. Repeat on both sidewalls.

Install TRIM14

STEP 37

REQUIRED PARTS

(4) TRIM14

FAST12

ACC50

TRIM14

EAVE TRIM

EAVE STRUT

TRIM14

ACC50

INSIDE CLOSURE

WALL PANEL

Summary of Contents for Centra Series

Page 2: ......

Page 75: ......

Page 76: ...Copyright 2021 Central States Manufacturing Inc All Rights Reserved centralstatesmfg com ...