If there is space to mount the rack underneath without fouling the ground as the

gate moves, the following are the pros and cons:

Pros

The rack is more hidden from view

It provides a very effective anti-lift bracket

It ensures that as the gate beds in, the rack does not drop onto the pinion

loading the operator unnecessarily

Cons

Rack teeth face up vertically potentially collecting dirt

Custom bracket

With careful selection of the rack configuration, and operator vertical height,

mounting of the rack could in some cases be greatly simplified.

If a theft-resistant cage is required, be sure to leave enough clearance from

pillars, etc.

If using nylon angle rack please ensure that the weight and pull force of the

gate do not exceed the strength limit of the rack

10. Operator installation

Locate operator position

To ensure operator does not protrude into driveway, install base plate at least flush with

the driveway entrance

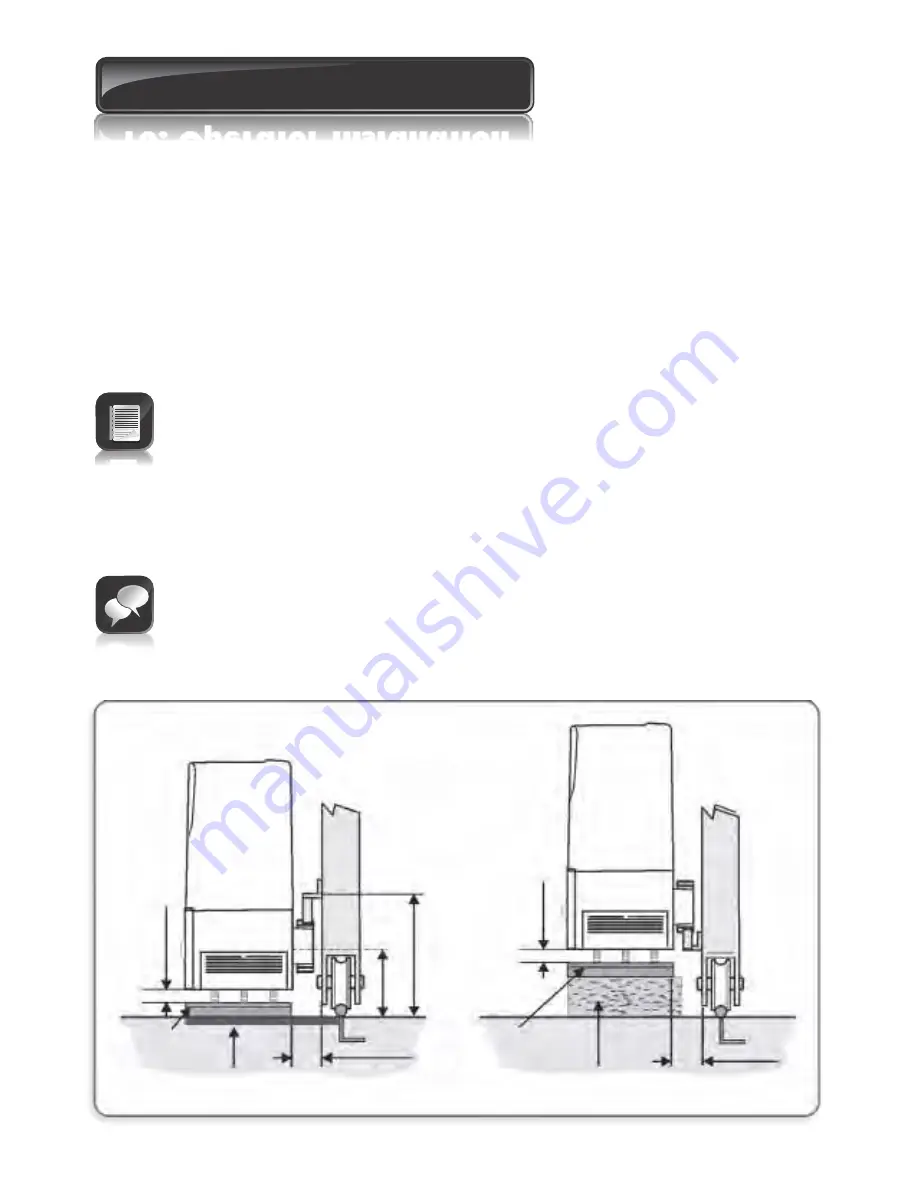

Determine a suitable position and vertical height for the operator by considering Figures

8, 9 and 10

It is typical to mount the rack above the pinion as shown in Figures 8A, 9A and 10A for

each type of rack considered. However, in each case, Figures 8B, 9B and 10B show the

rack mounted underneath

page 16

* Includes 3mm clearance required between rack and pinion

FIGURE 8A Steel rack, above pinion

FIGURE 8B Steel rack, below pinion

32 - 50

5

5

32 - 50

(Recommended to

allow for adjustment)

(Recommended to

allow for adjustment)

82

146*

Foundation

plate

Foundation

plate

Flat bar welded to

foundation plate and rail

Raised foundation