page 47

www.centsys.com

8.1.1 How and when to do maintenance

Maintenance should be carried out at regular intervals.

The list below can be used as a schedule for maintenance procedures.

As a minimum, the following maintenance procedures should be performed on a basis

that is consistent with the daily usage of the unit:

1.

Remove the

DOSS Sensor and check whether it is in good working condition. Do this

by first removing the DOSS from the gearbox, then cleaning the sensor, removing all

dust and dirt from the optic sensors

2.

Check the battery under load; it must not drop below 10,5V. Use the information

screen to monitor the voltages. Check the battery terminals for signs of acid leakage,

and, if necessary, clean the terminals and battery leads

3. Disconnect the battery and ensure that the charger delivers 14.20V on the relevant

information screen

4. Check all the wires going into the

connectors for tightness and

remove any dirt that has

accumulated

MAINTENANCE

SECTION 8

8. Maintenance

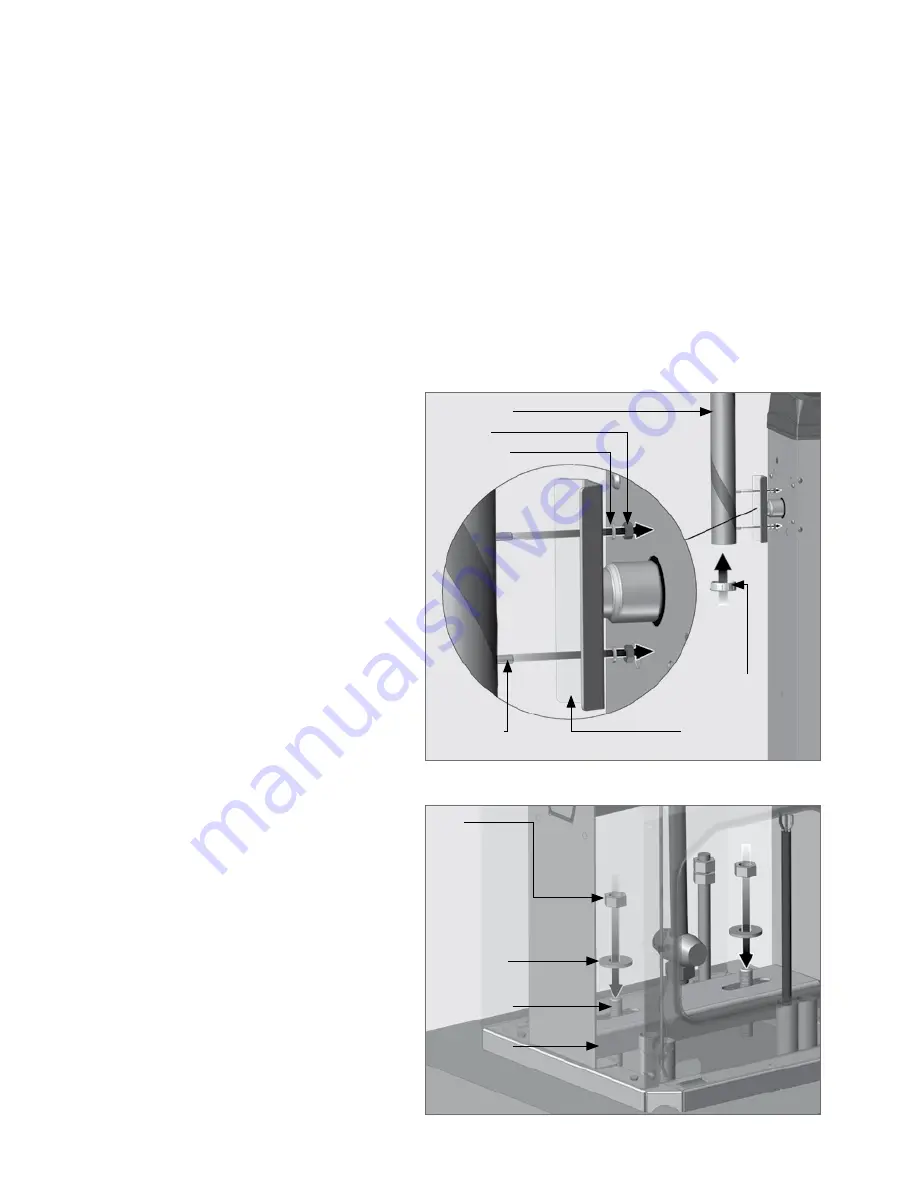

8.1.2 Mechanical checks

Tighten the M8 nuts securing the pole

to the boom-coupler (Figure 35).

Ensure that the barrier is still bolted

tightly to the plinth (Figure 36).

FIGURE 35

Boom pole

M8 Nut

M8 Spring

washer

Threaded

stud

Coupler

in vertical

position

End Cap

FIGURE 36

Barrier

hold-down

stud

Nut

Heavy duty

Washer

(Supplied)

Hold-down

bracket

Summary of Contents for SECTOR II

Page 82: ...page 82 www centsys com Notes...

Page 83: ...page 83 www centsys com Notes...