page 18

www.centsys.com

S

ECTION

6

OPERA

TOR

INS

TALLATION

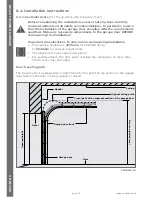

FIGURE 15

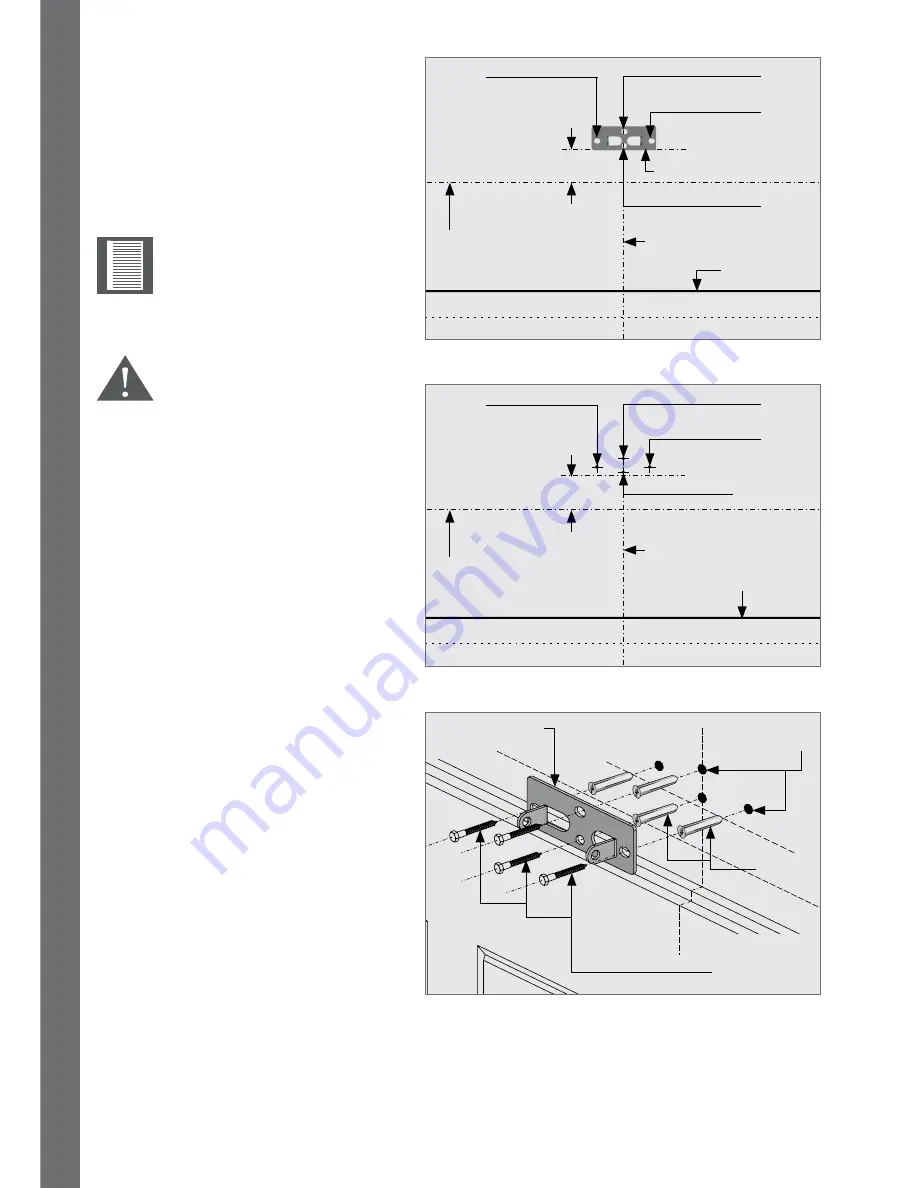

FIGURE 16

FIGURE 17

Garage door center line

Garage door center line

Header bracket

(Note the orientation)

Hole B

Hole C

Hole D

(Optional)

Hole B

Hole C

Hole D

(Optional)

Coach screws

Hole A

Hole A

Header bracket

Plugs

11mm

Holes

Garage door

Garage door

Highest arcing

point

Highest arcing

point

0-50mm

0-50mm

Place the header bracket on the

wall as shown in Figure 15.

Ensure that the

bottom edge

of

the bracket is level, and

no more

than 50mm above

the highest

arcing point of the garage door.

Mark the location of the four screw

holes (Hole A, B, C and D[optional]).

Drill four 11mm diameter holes in

position of ‘Hole A’, ‘Hole B’, ‘Hole

C’ and ‘Hole D’(optional), at least

50mm deep.

Mounting the drive rail

more than 50mm above

the highest arcing point

of the garage door may

cause the drive rail to

flex excessively.

Note the orientation of the

header bracket.

Place a fischer plug in each hole,

followed by the header bracket.

Secure it in position with at least

three coach screws (supplied)

(13mm hexagonal head).