2

Introduction

Congratulations on your purchase of Century Helicopter Product’s latest version of our HAWK series RC helicopter model. The

Hawk Pro helicopter is not only ideal for beginners new to the hobby, but also for the intermediate and right on through to the

expert and 3D flyers. A 6 channel helicopter radio is recommended as the bare minimum to take advantage of the helicopter

programming included in these radios. The expert to 3D flyers would certainly be using a good 8 to 10 channel helicopter radio.

You may wish to check with us or your local dealer for compatible components.

Warning

This radio controlled model is not a toy! It is a precision machine requiring proper assembly and setup to avoid accidents. It is

the responsibility of the owner to operate this product in a safe manner as it can inflict serious injury . It is recommended that

if you are in doubt of your abilities, seek assistance from experienced radio control helicopter modelers and associations. As

manufacturer, we assume no liability for the use of this product.

Pre-assembly Information

Upon opening the kit, all the major component parts are packaged in numbered bags to correspond to specific sections of the

manual, greatly facilitating assembly. Various assemblies have been pre-assembled, only requiring the final assembly and in-

stallation of the various sub-assemblies. The screws and nuts required for each step are packaged in the same bag as the parts

for that step. Be careful not to lose any of the hardware when opening each bag. Care has been taken in filling and packing of

each bag.

Warranty

Your new equipment is warranted to the original purchaser against manufacturer defects in material and workmanship for 30

days from the date of purchase. During this period, Century Helicopter Products will repair or replace, at our discretion, any

component that is found to be factory defective at no cost to the purchaser. This warranty is limited to the original purchaser

and is not transferable. This warranty does not apply to any unit which has been improperly installed, mishandled, abused, or

damaged in a crash, or to any unit which has been repaired or altered by any unauthorized agencies. Under no circumstances

will the buyer be entitled to consequential or incidental damages. This limited warranty gives you specific legal rights. You also

have other rights which may vary from state.

Table of Contents

Table of Contents & Introduction ................................................................................................................2

Required Items and Tools for Assembly .....................................................................................................3

Package contents ......................................................................................................................................4

Section 1 Preparing the engine ..................................................................................................................5

Section 2 Assembling the main frame ........................................................................................................5

Section 3 Assembling the servo tray ..........................................................................................................6

Section 4 Fuel tank & fittings ......................................................................................................................6

Section 5 Muffler & fuel tubing ...................................................................................................................7

Section 6 Flybar & rotor head assembly ....................................................................................................7

Section 7 Landing gear ..............................................................................................................................8

Section 8 Tail boom & drive system ...........................................................................................................8

Section 9 Tail boom support struts and tail fin set ......................................................................................9

Section 10 Tail control rod and pitch control ...............................................................................................9

Section 11 Throttle & collective linkage ......................................................................................................9

Section 12 Cyclic servo linkage ................................................................................................................10

Section 13 Rotor head linkage .................................................................................................................10

Section 14 Connect the electronics ..........................................................................................................10

Section 15 Main rotor blade installation ...................................................................................................10

Section 16 Antenna routing ...................................................................................................................... 11

Section 17 Mounting the canopy .............................................................................................................. 11

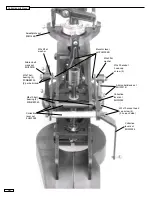

Main sub assemblies (exploded views) ...............................................................................................12-17

Replacement part list and photos ........................................................................................................18-20

Upgrades .............................................................................................................................................21-22

Century Helicopter Products

1740 Junction Ave. C.

San Jose, CA 95112

Fax: (408) 451-1156

www.centuryheli.com