Section 5: Muffler & fuel routing

5.2

5.3

5.4

Section 6: Flybar & head assembly

6.1

5.1

Install the pressure nipple using a high temperature

adhesive (thread lock) to the top of the muffler and

the 4mm plug screw to the bottom (5.1). Bolt the

muffler to the engine (5.2) flush (no gasket required)

using thread lock. Connect fuel tube between the

fuel pickup in the tank and the carb on the engine

with as little slack as possible (5.3). Connection

between the carb and the fuel pickup tube (short

straight) should be level (keeps fuel draw rate in

inverted flight). Connect the fuel tank air tube (long

curved) to the muffler pressure nipple (5.3).

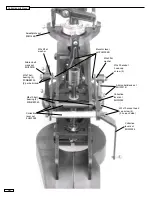

Install the flybar, flybar control arms,

weights and paddles into the rotor

head seesaw assembly as shown (6.1).

First slide the flybar in place through

the seesaw assembly. Then slide the

ball bearings included with the two ball

bearings into the seesaw cups on each

end. Then slide the M3x6 plastic spacers

on to each side of the flybar. Next slide

the 2 flybar control arms as shown

(6.1) Use thread lock on the set screws

connecting the flybar weights to the flybar

(6.2 - 6.3). Align the flybar paddles and

control arms level to the seesaw assembly

(LEADING EDGE OF PADDLES MUST

GO CLOCKWISE). The assembled flybar

must be the same length on each side of

the rotor head. Install the completed rotor

head to the main shaft (6.4) with one 3x16

cap screw and M3 locknut.

6.2

6.3

6.4

Using thread lock

M4x5 set screw (2)

Using thread lock

M3x3 set screw (2)

M3x16 socket head

cap screw (1)

M3 locknut (1)

Using thread lock:

Hardware provided with muffler

Using thread

lock:

3x25 socket

head cap

screw (2)

M3x7 Ball

bearing (2)

7

Flybar

control

arm

Flybar weight

Flybar paddle

(Optional Toki muffler for Toki .40 engine shown. Toki muffler is

supplied with a Hawk Pro “Toki engine and muffler combo”)

Leading edge

Trailing edge

M4x5 Set

screw

M3x4 Set

screw

M3x6

spacer (2)

Seesaw

assembly

(bearing cup)