Radikal Gasser

Page 35

1

2

3

4

5

6

7

8

9

10

11

12

13

4x6x0.5 CNLR1006

CNBB410

Ø4x30 CNE533

CNM3x4SS

CNM3x12CS

M3 CNM3LOCK

CNM3x8FHCS

2

CNLR1006

Micro Washer(

垫片

)4x6x0.5

2

Bearing(

滚珠轴承

)4x10x4

CNBB410

1

CNE538

Transmission Gear(

皮带输入齿轮

)

1

CNE533

Lock Pin(

插销

)M4x30

2

Upper Transmission Case(

尾管夹片

)

2

Set Screw(

无头内六角螺丝

)M3x4

CNM3x4SS

4

(

杯头内六角螺丝

)M3x12

CNM3x12CS

2

Long Hex Spacers(

长六角铝柱

)L=52MM

M3 Locknut(M3

螺母

)

4

CNM3LOCK

1

2

Head Lock Gyro Plate(

陀螺仪板

)

Flush Head Cap Screws(

斜头内六角螺丝

)M3x8

CNM3x8FHCS

1

1

Tail Belt Drive(

皮带

)

Tailboom(

尾管

)

HI6060B

HW6007GS

HI6117A

HI6631

HW6062G

No.

Description

Qty

1

2

3

4

6

7

5

8

9

10

Part #

12

13

11

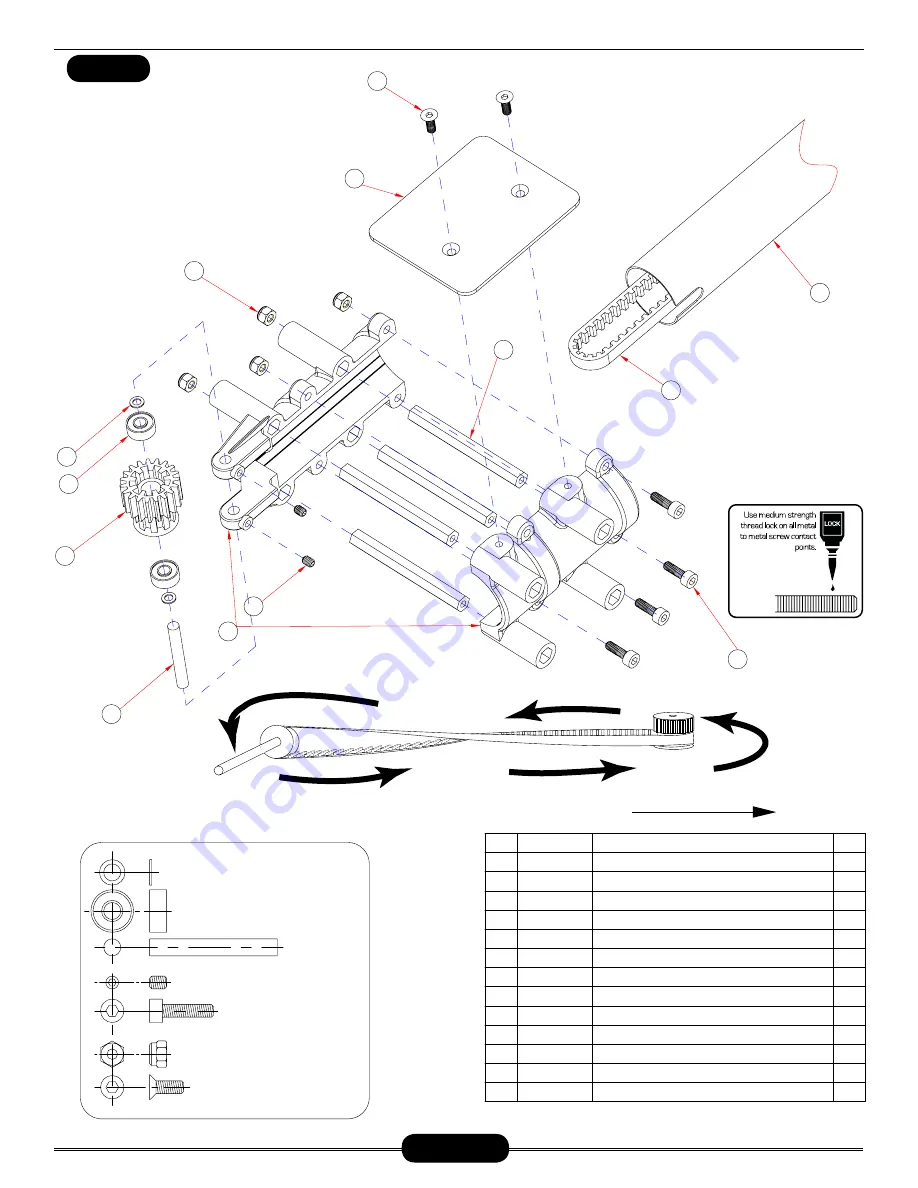

BAG 4

You may notice the boom and the

tail transmission case is scuffed.

This is done during the manu-

facturing process to ensure a

proper grip.

HELICOPTER NOSE

TAIL OUTPUT SHAFT

TRANSMISSION CASE

When orienting the belt the front trans-

mission pulley as viewed from the top

should be turning counter-clockwise.

When the belt is twisted as shown below,

the rear tail pulley should turn counter

clockwise when viewed directly on from

the right side of the helicopter.

To adjust belt tension, pull for-

ward on the front transmission

box and tighten the screws.

The belt should be tight enough

that it should not travel past the

half way point when pressed

down from the back. If it is too

tight, you will cause excessive

drag.

If you have carbon fiber frames, just add a “C” to the end of the frame

part number.

Button Head Cap Screw