9

/

15

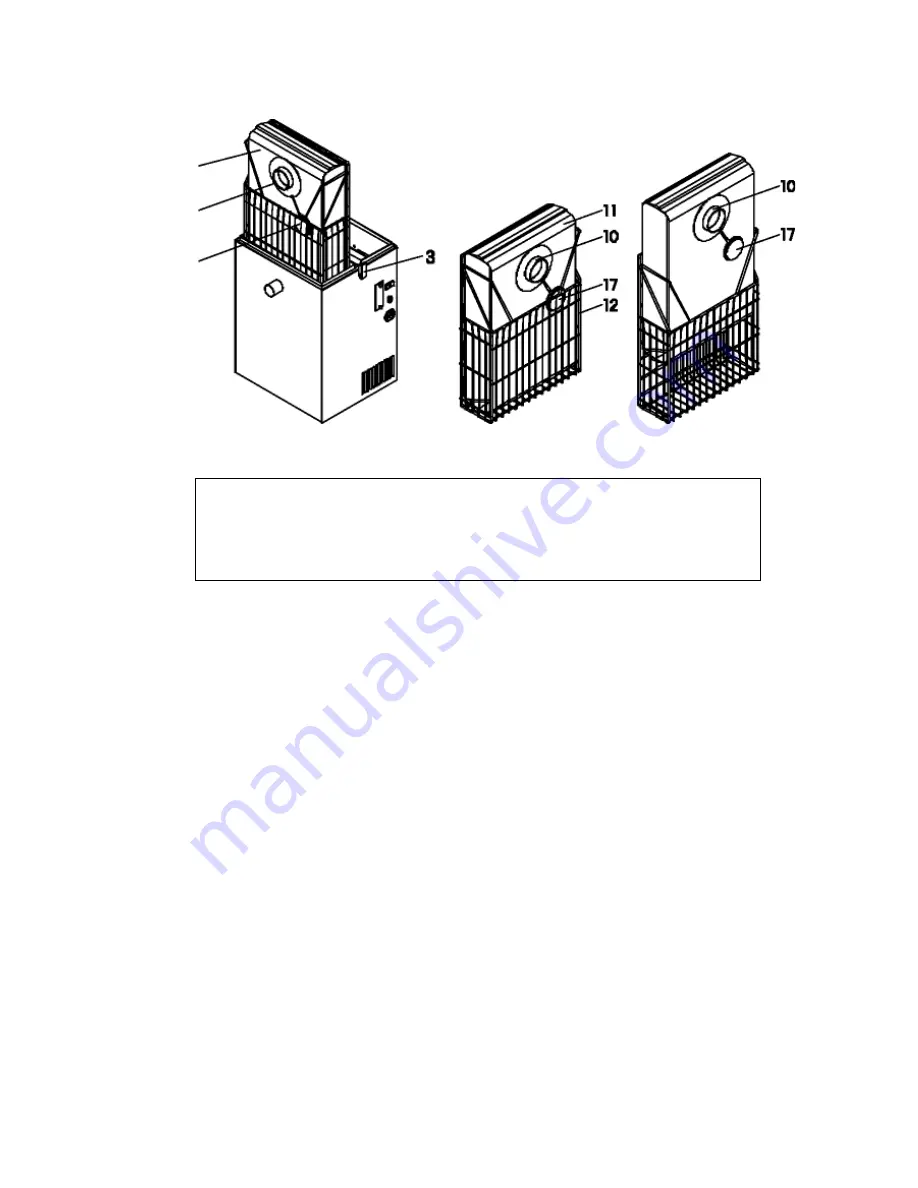

Fig. 4: Removing the filter bag

Caution

The single-use filter bags must never be emptied and reused. Not only might

this constitute a health hazard, but it would also impair the function of the

unit.

Caution

Do not use pressurized air to remove any dust present in the filtration

chamber (20).

Do not allow any foreign matter to enter the air intake opening (26) because

this might damage the vacuum motor.

5.

Insert the new filter bag snugly and check the filtration module (see Section

4.2).

4.2 Inserting the filter bag

(see Fig. 1 on page 4 and Figs. 6 and 7 on page 9)

1.

Fold new filter bag (11) as shown in Fig. 5 and insert into basket as shown

(12).