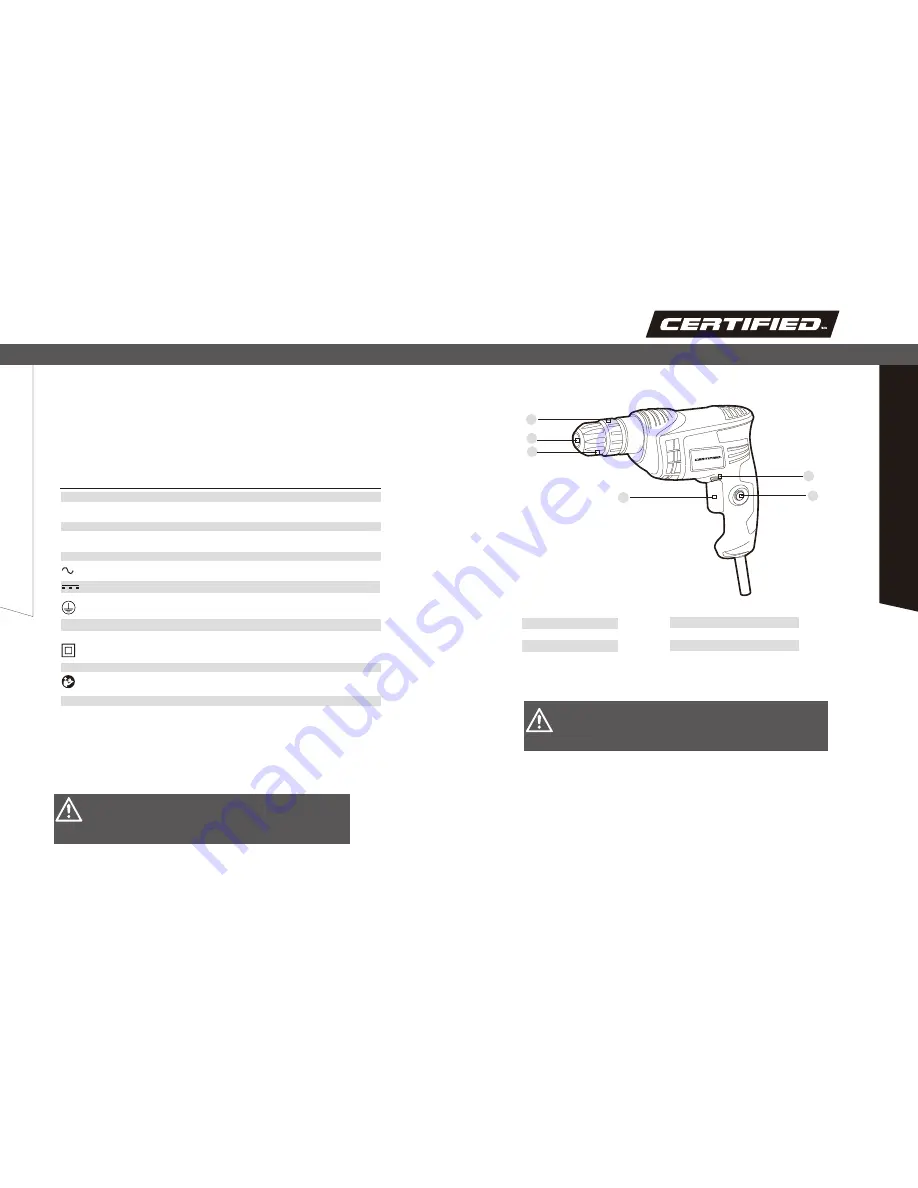

Know your tool

No.

Description

No.

Description

1

Chuck Jaws

5

Lock-on Button

2

Chuck S leeve

T rigger

3

Collar

4

Before attempting to use this tool, become familiar with all of its operating features and

safety requirements. For optimum performance and safety, read the following operating

instructions carefully before using.

Do not allow familiarity with the drill to cause a lack of alertness. A fraction of a second of

carelessness is enough to cause severe injury.

Safety guidelines for corded drill

Use the auxiliary handles if supplied with the tool. Loss of control can cause personal injury.

•

Hold the power tool by the insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire

may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

•

The label on your tool may include the following symbols. The symbols and their

definitions are as follows:

V Volts

A Amperes

Hz Hertz

W Watts

min Minutes

Alternating

Current

Direct current

n

0

No-load speed Rational

speed

,

at no load.

Class II Construction Double-insulated construction.

/

min Per

Minute

Grounding terminal

BPM Beats per minute

Read

The

Operator’s

Manual

To reduce the risk of injury user must read and

understand

,

.

•

Use clamps or another practical way to support the workpiece and secure it to a stable

platform. Holding the workpiece by hand or against your body is unstable and may lead to loss of control.

•

Inspect the tool cords periodically and, if damaged, have them repaired by a qualified

repair person. Constantly stay aware of the cord location. Following this rule will reduce the risk of

Corded drill and instruction manual.

Remove the drill from the package and examine it carefully. Do not discard the carton or

any packaging material until all parts have been examined.

7

8

WARNING!

S

A

FE

TY G

U

ID

EL

IN

ES

D

ES

C

R

IP

TI

O

N

WARNING!

•

electric

shock

or

fire

.

Contents

:

Symbol

Name Designation/Explanation

Type or a characteristic of current.

Revolutions, strokes, surface speed, orbits minute.

operator’s

manual

before

using

this

product

Switch

3

1

2

4

5

6

6

Type of current.

Time

.

Power.

Frequency (cycles per second).

Current

.

Voltage.

model number 054-5847-8

Direction of Rotation Selector