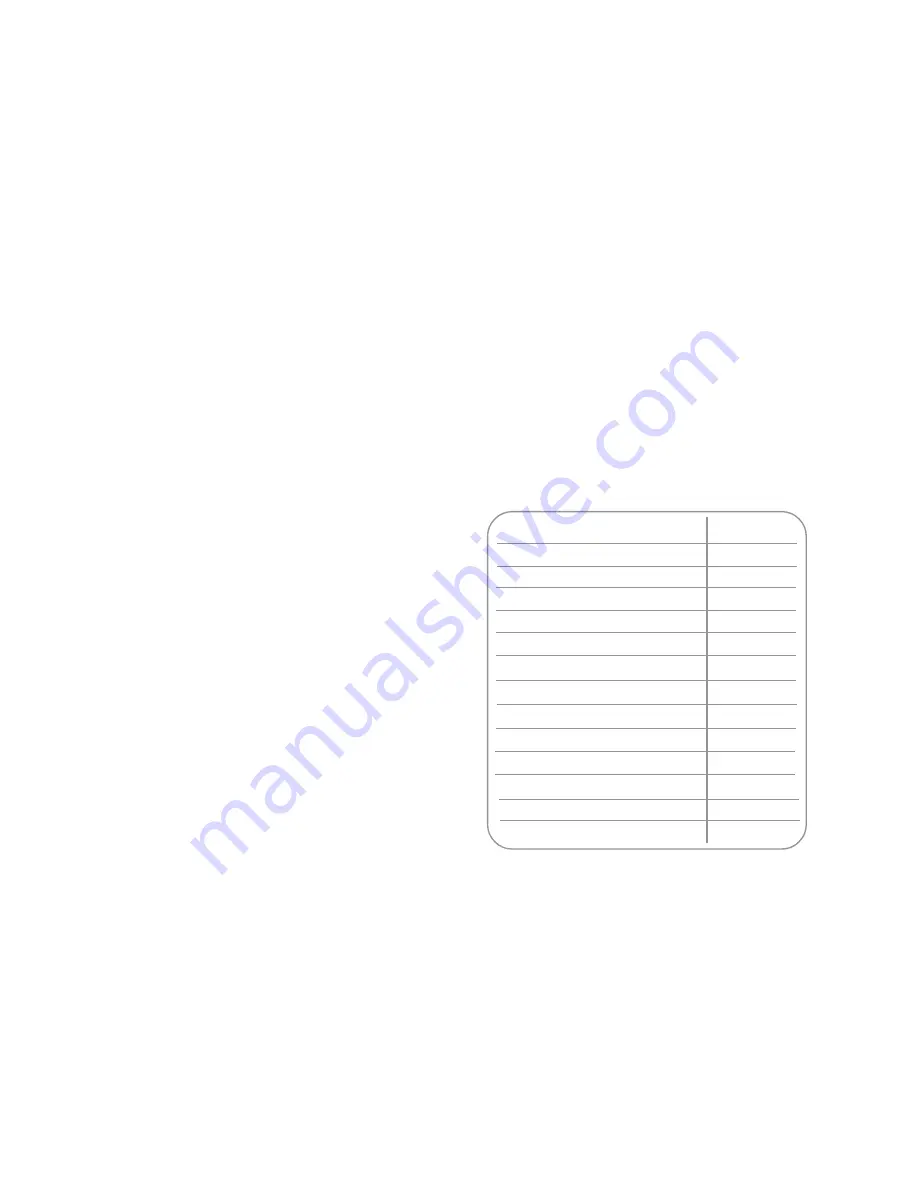

Terminal Position

Minimum

Below window or vent

300 mm

Below gutter or pipes

75 mm

Below eaves

200 mm

Below balcony or roof

200 mm

From a window

200 mm

From vertical pipe

75 mm

From corners

300 mm

Above ground, roof or balcony

300 mm

From facing surface

600 mm

From facing terminal

1200 mm

From opening under a car port

1200 mm

Vertically from a terminal

1500 mm

Horizontally from a terminal

300 mm

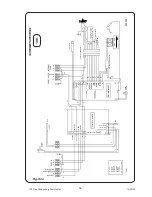

An Over Temperature Thermostat (Overheat).

Internal Pump control with run on.

Pool Pump control with run on and out-of-season

exercise. (Requires external contactor)

Pool Temperature and Setting display. Engineer

selectable °C or °F.

User Indicators for Pool, Heating, Overheat, and

Service.

Engineer indicators of all switched outputs for

simple diagnosis.

Priority selection of Pool or Heating, engineer

selectable.

Memory of: Filter occurrences.

Sensor failure detection and indication.

Control self checking with fault indication.

For more detail see the

Commissioning (6:1) an

Fault Finding (7:1) sections.

2:5 Gas Supply

The Local Gas Region should be consulted, at the

installation planning stage, in order to establish the

availability of an adequate supply of gas.

An existing service pipe must NOT be used without

prior consultation with the Local Gas Region, or by

a local Gas region contractor. An existing meter

should be checked preferably by the Gas region, to

ensure that the meter is adequate to deal with the

rate of gas supply required.

Installation pipes should be fitted in accordance

with BS.6891

Do NOT use pipes of a smaller size than the Heater

inlet gas connection.

3 FLUEING

Detailed recommendations for flueing are given in

BS.5440: 1. The following notes are intended for

general guidance.

1. Be aware of the plume from the flue and the

wetting effect it has to adjacent property.

2. The flue can be taken upwards, left, right or to

the rear of the appliance.

3. The Heater is supplied with a Twin Pipe flue

suitable for terminating on an outside wall 1

metre away. More complex and lengthy flues

are possible, please consult the Flue Application

Guide for designs and the components.

4. The Heater MUST be installed so that the

terminal is exposed to external air.

5. It is important that the terminal allows the free

passage of air across it at all times.

Table 1.

IMPORTANT.

It is absolutely ESSENTIAL to ensure, in practice,

that products of combustion discharging from the

terminal cannot re-enter the building, or any other

adjacent building, through ventilators, windows,

doors, other sources of natural air infiltration or

forced ventilation/air conditioning.

If this should occur, the appliance MUST be

turned OFF IMMEDIATELY and the Local Gas

Region consulted.

6. The acceptable spacing from the terminal to

obstructions and ventilation openings are

specified in Table 1.

7. Because the flue gases and terminal are at very

low temperature it is not necessary to fit a

Terminal guard to protect against burns. If a

guard is required for any other reason the

following is recommended.

For the Twin Flue Terminal:

Model B (black plastic coated).

For the Single Flue Terminal:

Model H (black plastic coated).

All are available from:

Tower Flue Components Ltd.

Tower House.

Vale Rise.

Tonbridge

KENT

TN9 1TB

01732 351555

7

100 Gas Condensing Pool Heater

01/06/02