SECTION 7

CESSNA

AIRPLANE AND SYSTEMS DESCRIPTION

MODEL 172S NAV III

ENGINE

(Continued)

ENGINE LUBRICATION SYSTEM

The engine utilizes a full-pressure, wet-sump type lubrication

system with aviation-grade oil used as the lubricant. The capacity of

the engine sump (located on the bottom of the engine) is eight

quarts. Oil is drawn from the sump through an oil suction strainer

screen into the engine-driven oil pump. From the pump, oil is routed

to a bypass valve. If the oil is cold, the bypass valve allows the oil to

bypass the oil cooler and go directly from the pump to the full flow

oil filter. If the oil is hot, the bypass valve routes the oil out of the

accessory housing and into a flexible hose leading to the oil cooler

on the right, rear engine baffle. Pressure oil from the cooler returns

to the accessory housing where it passes through the full flow oil

filter. The filter oil then enters a pressure relief valve which

regulates engine oil pressure by allowing excessive oil to return to

the sump while the balance of the oil is circulated to various engine

parts for lubrication. Residual oil is returned to the sump by gravity

flow.

An oil filler cap/oil dipstick is located at the right rear of the engine.

The filler cap/ dipstick is accessible through an access door on the

top right side of the engine cowling. The engine should not be

operated on less than five quarts of oil. For extended flight, fill to

eight quarts (dipstick indication only). For engine oil grade and

specifications, refer to Section 8 of this handbook.

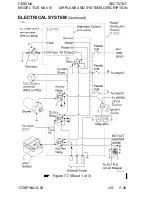

IGNITION AND STARTER SYSTEM

Engine ignition is provided by two engine-driven magnetos, and two

spark plugs in each cylinder. The right magneto fires the lower right

and upper left spark plugs, and the left magneto fires the lower left

and upper right spark plugs. Normal operation is conducted with

both magnetos due to the more complete burning of the fuel/air

mixture with dual ignition.

(Continued Next Page)

7-34 U.S.

172SPHAUS-00