7 Troubleshooting and after-sales services

7.3 Error message

96

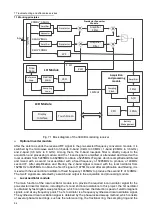

7.2.2.1 Problems During Startup

If the 3943 monitoring reveiver fails during startup, it may involve multiple aspects such as the power

supply, processor hardware, and instrument setup. This section helps to analyze the possible failures in

the startup process and the causes according to the power-on startup steps of the 3943B monitoring

receiver.

1) Orange standby light not on

When the adapter is connected, the power indicator in the upper right corner of the front panel will turn

orange. If the orange standby light is not on, check whether the adapter indicator is lit, and if available,

use a multimeter to measure whether the output voltage of the adapter is about 18V. If the adapter

indicator lights up or the output voltage of the adapter is 18V, the instrument power supply may be faulty.

Please contact the customer service center according to the contact information provided in this manual

and provide the collected error information, we will assist you to solve the problem as soon as possible.

2) No screen display

When 3943B monitoring receiver is powered on, the power indicator in the upper right corner of the front

panel from orange to green, while the screen does not light up, connect the network cable, if the network

port light blinks, and the network can be connected. It indicates that the instrument is powered on and

the CPU is working normally, and it may be that the LCD is malfunctioning; if the net port light is not on, it

may be that the power supply is abnormal. Please contact the customer service center according to the

contact information provided in this manual and provide the collected error information, we will assist you

to solve the problem as soon as possible.

7.2.2.2 Instrument Setup Problems

When the 3943B monitoring receiver enters the normal scanning state, a continuously refreshed trace

can be seen on the interface. However, if some parameters of the instrument are not set properly, the

user may not be able to see the desired track or signal. If the refresh of the track or the signal display is

malfunctioning, please check the following settings first.

1)

The track is not refreshed or refreshed abnormally

If the track on the interface does not refresh, or does not refresh properly, please refer to the following

steps:

a) Check if the machine is in running state, if the setting is correct and the track still does not refresh,

please proceed to the next step.

b) Turn on the frequency scale and see if the X1 and X2 readings change. If there is a reading change,

it may be due to the setting reason, for example, the instrument reference level is too high and so on,

which causes the traces to be below the screen, thus the traces cannot be seen, in this case, you can

slide the spectrum window up and down, beat the reference level smaller, and observe the traces again.

If the marker reading stays still, it may be a trackback error, please try to reboot the machine, and if the

fault still can't be eliminated, please contact the customer service center according to the contact

information provided in this manual and provide the collected error information, we will assist you to

solve the problem as fast as possible.

7.3 Error message

The monitoring receiver uses two ways to record errors that occur during measurements: a front panel

display error message queue and an SCPI (remote control mode) error message queue, both of which

are stored and managed separately.

E r r o r m e s s a g e f i l e

… … … … … … … … ……… … … … … … … … ……… … … … … … … … 1 05

E r r o r d e s c r i p t i o n

… … … … … … … … … … … … … … … … … … … … … … … … … … … … 1 0 6

7.3.1 Error message file

The random CD stores the file errormessage.pdf, which records the complete error message. The error

list consists of the error number and the error description. For multiple error messages corresponding to

the same error serial number, alphabetical order is used to distinguish different error messages.