5.2 Intake Pipe, Cylinder Head and Cylinder Body

05-27

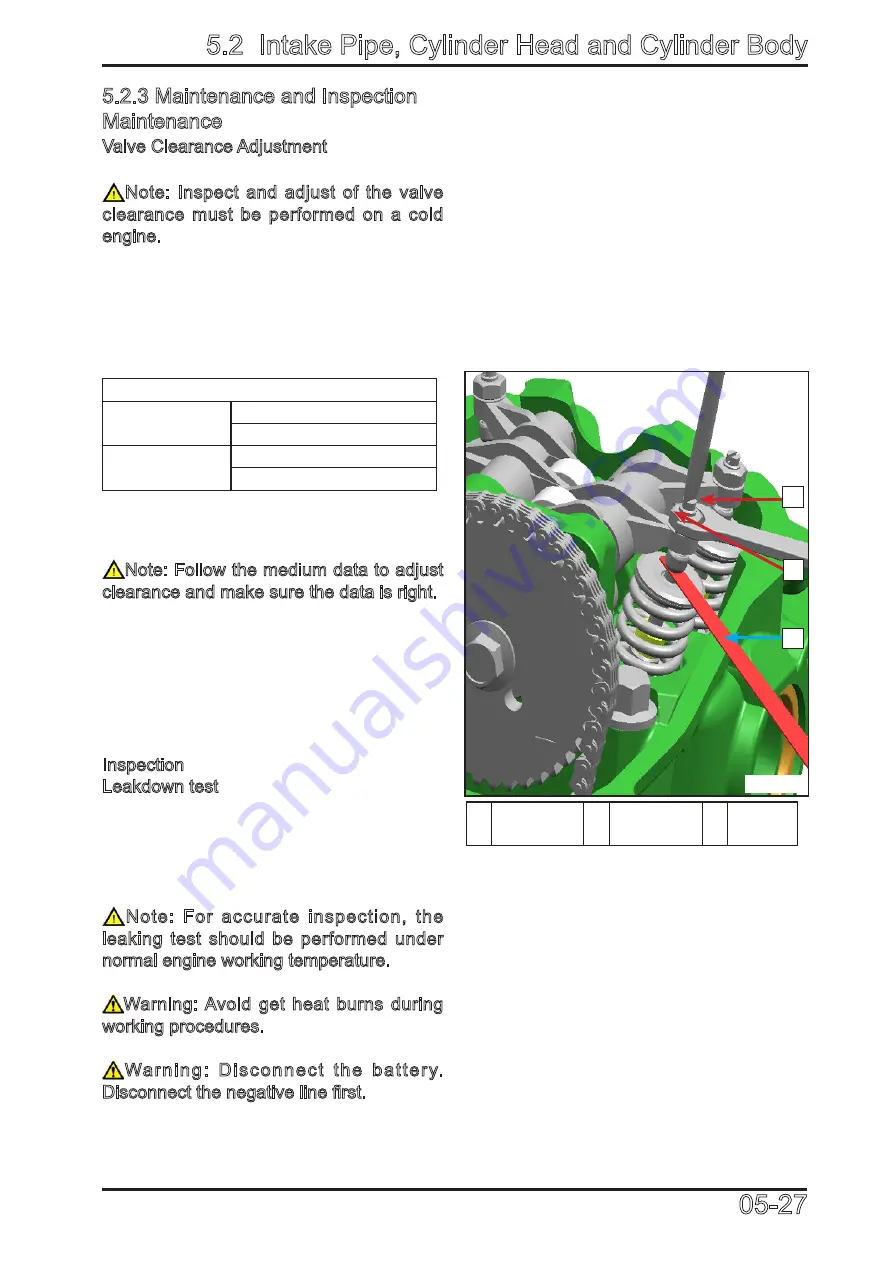

1 Adjusting

screw

2 Clearance

gauge

3 Locking

nut

052701

5.2.3 Maintenance and Inspection

Maintenance

Valve Clearance Adjustment

Note: Inspect and adjust of the valve

clearance must be performed on a cold

engine.

Remove the cylinder head cover.

Turn the crankshaft until the cylinder is at

TDC. See camshaft timing in this chapter.

Use clearance gauge to test the valve

clearance.

Valve clearance

Intake

0.06 mm~0.14 mm

(0.0024 in ~ 0.0055 in)

Exhaust

0.11 mm~0.19 mm

(0.0043 in ~ 0.0075 in)

If the clearance is out of limit, follow the

steps below to adjust:

Note: Follow the medium data to adjust

clearance and make sure the data is right.

Tighten up the locking nut after getting the

right clearance.

Repeat the work on every valve.

Check the valve clearance again before

installing the cylinder head cover.

Inspection

Leakdown test

Confirm the items below before cylinder

leaking test :

—Tight up the clamp

—Radiator and hose

Note: For accurate inspection, the

leaking test should be performed under

normal engine working temperature.

Warning: Avoid get heat burns during

working procedures.

Warning: Disconnect the battery.

Disconnect the negative line first.

3

2

1

Summary of Contents for CF1000ATR 2018

Page 1: ...CFMOTO SERVICE MANUAL CF1000AU CF1000ATR CFORCE 1000 ...

Page 81: ...CFMOTO 05 6 5 1 4 EIN Location EIN Location Engine left side Engine right side 050601 050602 ...

Page 351: ...06 Vehicle chassis 06 41 6 7 3 Front and rear CV shaft disassemble view 064101 064102 ...

Page 363: ...Appendix A ...

Page 364: ...Appendix B ...

Page 365: ...Appendix C ...