5.2 Intake Pipe, Cylinder Head and Cylinder Body

05-61

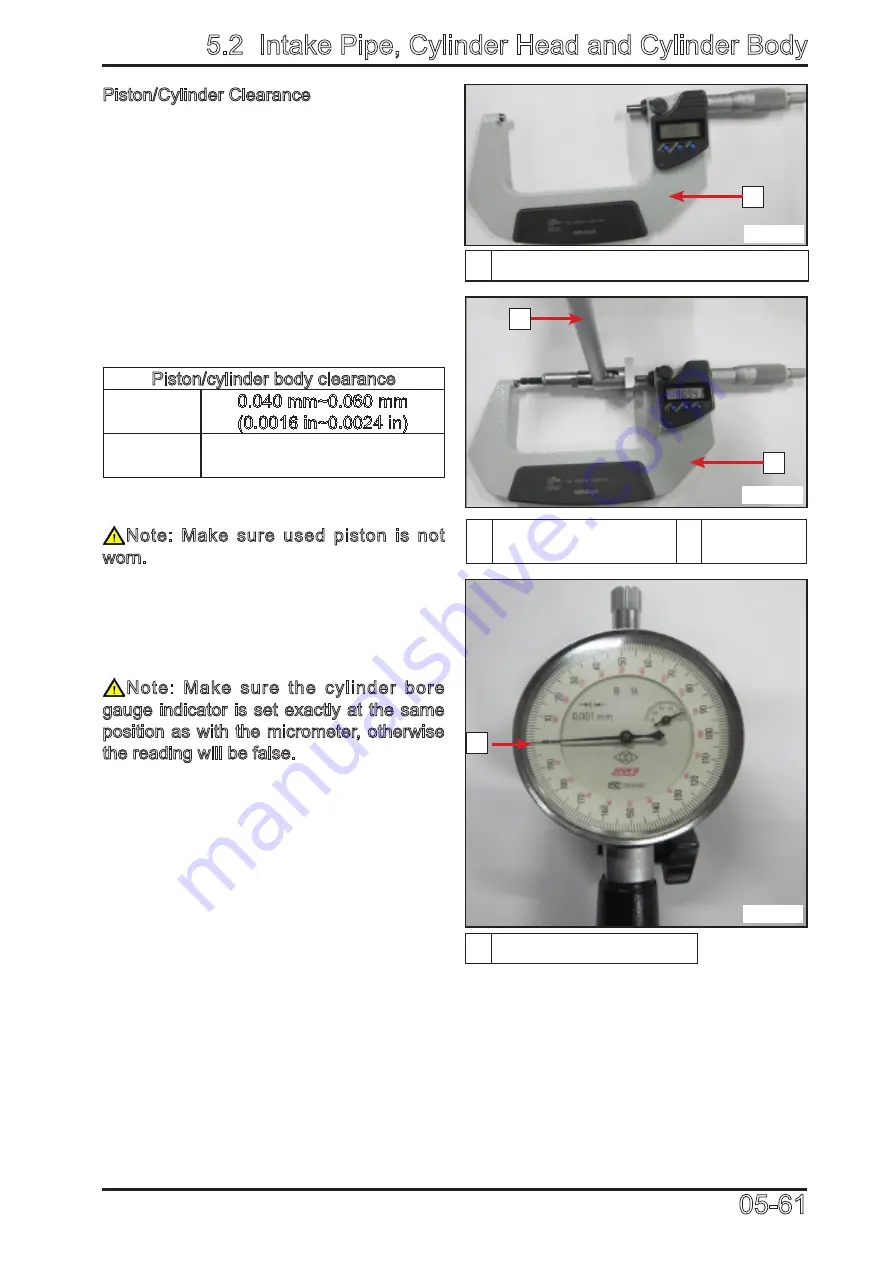

1 Micrometer Set to the Piston Dimension

1 Use Micrometer to

Adjust the Dial gauge 2 Dial Gauge

1 Indicator Set to 0 (zero)

056101

056103

056102

Piston/Cylinder Clearance

Adjust and lock micrometer to the piston

dimension.

With the micrometer set to the dimension,

adjust a cylinder bore gauge to the

micrometer dimension and set the indicator

to 0 (zero).

Position the dial bore gauge 20mm (0.787

in) above cylinder base, measuring

perpendicularly (90°) to piston pin axis.

Read the measurement on the cylinder

bore gauge. The result is the exact piston/

cylinder wall clearance.

Piston/cylinder body clearance

New

0.040 mm~0.060 mm

(0.0016 in~0.0024 in)

Service

limit

0.100 mm (0.0040 in)

Note: Make sure used piston is not

worn.

If clearance exceeds specified tolerance,

replace piston with a new one and

measure piston/cylinder clearance again.

Note: Make sure the cylinder bore

gauge indicator is set exactly at the same

position as with the micrometer, otherwise

the reading will be false.

2

1

1

1

Summary of Contents for CF1000ATR 2018

Page 1: ...CFMOTO SERVICE MANUAL CF1000AU CF1000ATR CFORCE 1000 ...

Page 81: ...CFMOTO 05 6 5 1 4 EIN Location EIN Location Engine left side Engine right side 050601 050602 ...

Page 351: ...06 Vehicle chassis 06 41 6 7 3 Front and rear CV shaft disassemble view 064101 064102 ...

Page 363: ...Appendix A ...

Page 364: ...Appendix B ...

Page 365: ...Appendix C ...