5.3 Crankcase, Crankshaft and Gears

05-91

059102

059101

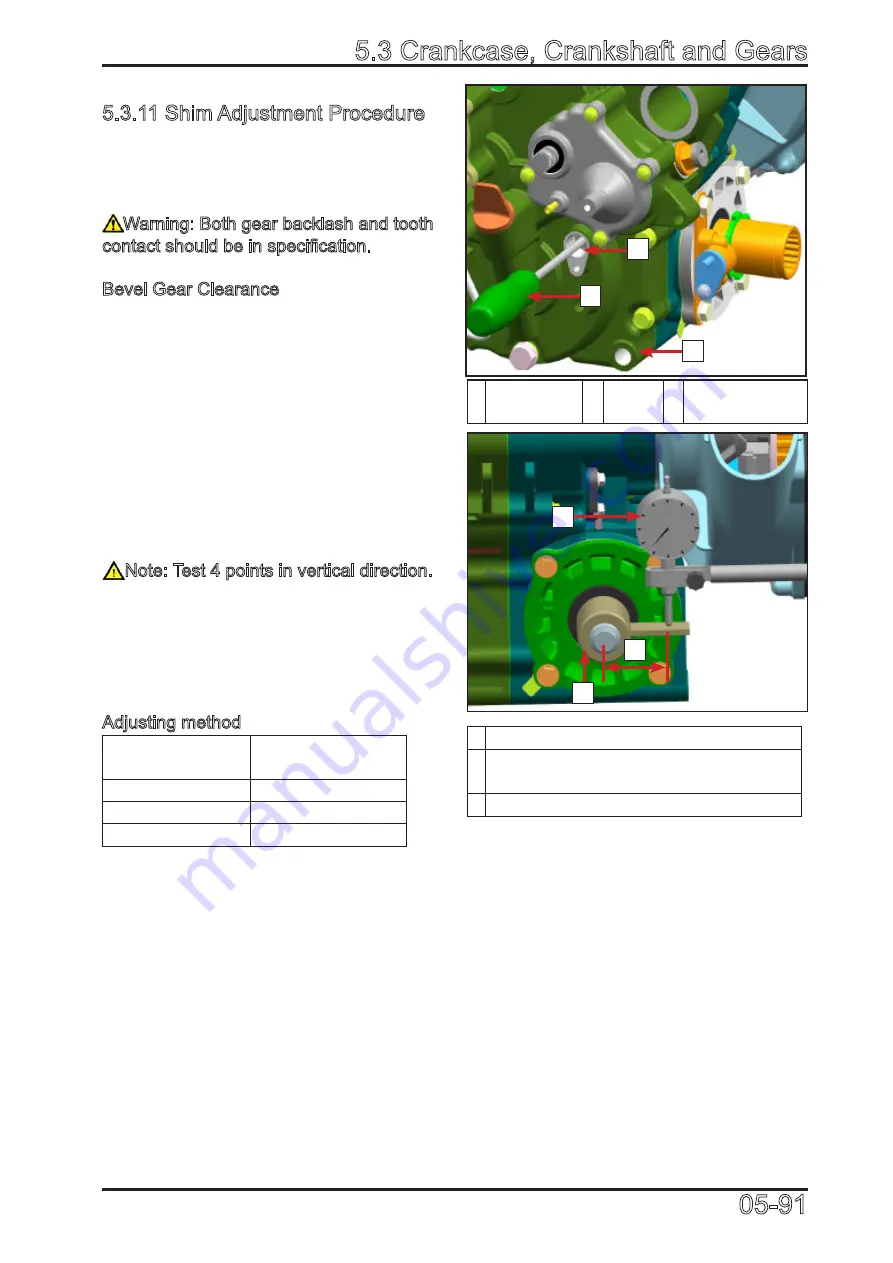

5.3.11 Shim Adjustment Procedure

When crankcase and/or drive pinion gear

and/or ring gear and/or bearing carrier are

replaced, the shim must be adjusted.

Warning: Both gear backlash and tooth

contact should be in specification.

Bevel Gear Clearance

Install the drive and driven bevel gear on

the crankcase. Set the gasket and close

the case . Then lock the case with several

bolts. Use a screw driver to go through the

sealing cap mounting hole and insert into

drive bevel bearing seat hole. Lock the

driven bevel gear.

Install bevel gear clearance measuring tool

(0JWA-062000-922-001) and dial gauge.

Turn the drive and driven bevel gear to

measure the clearance.

Note: Test 4 points in vertical direction.

If side clearance is not in standard, please

adjust the thickness of adjusting shim and

test the clearance again and again until

the clearance is up to standard. Bevel gear

clearance: 0.1mm~0.2mm

Adjusting method

Measure

clearance

Adjusting shim

thickness

<0.1mm

Get thicker

0.1mm~0.2mm

OK

>0.2mm

Get thinner

1 Crankcase

LH

2 Screw

Driver 3

Sealing Cap

Mounting Hole

1 46mm (1.81in)

2 Gear Clearance Measuring Tool (P/N:

0JWA-062000-922-001)

3 Dial Gauge

3

1

2

3

2

1

Summary of Contents for CF1000ATR 2018

Page 1: ...CFMOTO SERVICE MANUAL CF1000AU CF1000ATR CFORCE 1000 ...

Page 81: ...CFMOTO 05 6 5 1 4 EIN Location EIN Location Engine left side Engine right side 050601 050602 ...

Page 351: ...06 Vehicle chassis 06 41 6 7 3 Front and rear CV shaft disassemble view 064101 064102 ...

Page 363: ...Appendix A ...

Page 364: ...Appendix B ...

Page 365: ...Appendix C ...