6. Install the filler bolt and tighten to the specified torque.

Filler bolt (rear gear case) tightening torque: 23 N

m (2.3 m

kgf, 16 ft

lbf)

7. Check for oil leakage. If oil leakage is found, check for the cause.

Be sure no foreign material enters the rear gear case.

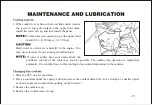

1. Place the machine on a level place.

2. Remove the oil filler bolt and check the oil level. It should be

up to the brim of the hole. If the level is low, add sufficient oil

to raise it to the specified level.

3. Install the oil filler bolt and tighten it to the specified torque.

Oil filler bolt tightening torque: 2

3 Nm (2.3 m

kgf, 16 ft

lbf)

1. Place the machine on a level place.

2. Place a container under the front gear case to catch the oil.

3. Remove the filler bolt and drain bolt to drain the oil.

Summary of Contents for CF500-A

Page 1: ...READ THIS MANUAL CAREFULLY...

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 65: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 146: ......