10

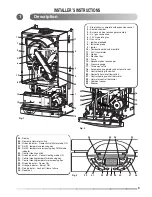

Making the Electrical Connections

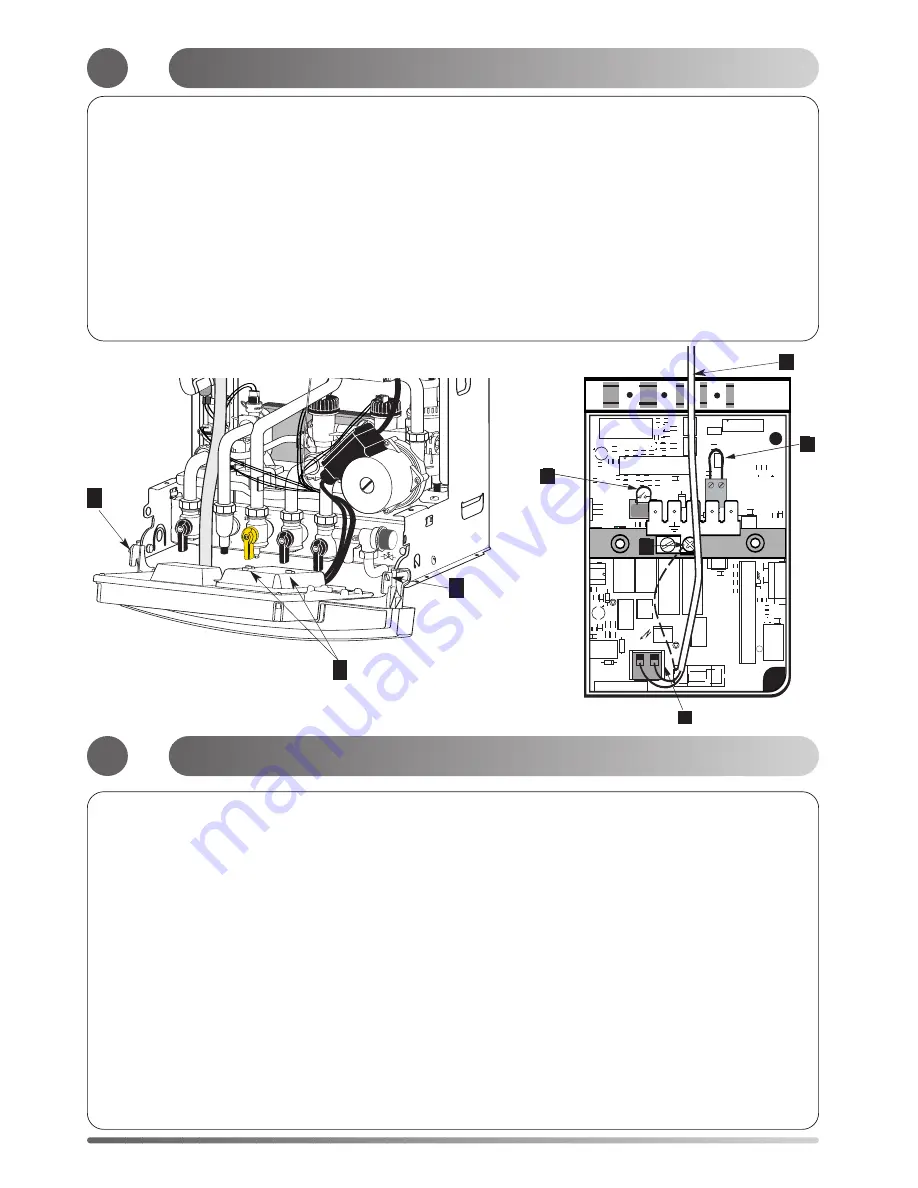

Hinge down the electrical box to gain access to the electrical connections. Push in the tabs P (fig 13) on either side of the

boiler and pivot the box forward. Undo the two retaining screws V , remove cover and remove cable clamp. C (fig 14)

Connect the live and neutral wires to the multipin plug leaving sufficient earth wire to connect to the earthing point

T fig 14 .

Note: The connections should be made so that should the lead be pulled from its anchorage, the current carrying wires

become taut before the earth wire.

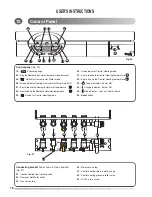

If using a room thermostat or other external control, they can be connected in place of the link S on the multipin

Plug (see fig. 14).

Note: Use only controls designed for voltage free switching or 24V supply. Do not connect to a 230V supply.

Connect multipin plug into the socket on the printed circuit board. Secure the cable using the cable clamp and

replace the cover. NB The room thermostat options setting can be made before replacing the electrical box cover (1 fig.14).

All necessary settings for room thermostat operations are described in paragraph 9 ADJUSTEMENTS AND SETTINGS.

T

R

C

O

M

R

E

P

8

M

/A

VITESSE

1

1

1

1

1

1

BUS

1

CALYDRA

OFF ON

11

12

2

1.23

OFF ON

11

12

1

SW2

PROG

SW1

TA

1

T2A

1

MCD

1

230V

MOTEUR

RL6

R

13

3

C

28

T15

R

36

R

35

C

80

C79

T1

6

R

34

T12

T11

R107

R

33

R

13

0

R129

D43

U9

Z7A

R

13

2

R16

R15

R14

C84

C

83

R

6a

Z4A

C78

R

L1

3

C73

Z6

R7a

Z7

Z4

D46

T10

T9

RL8

R

L7

A

RL7

RL10

R

L2

A

R

L2

RL9

R

11

9

R

11

8

R113

R

9

R

8

R7

R

6

R

31

R

32

R

29

R27

R

25

R24

R23

R19

R

18

R

17

R

14

0

R137

TH

4

R13

R12

R1

1

R

11

5

C82

C

81

T14

T13

R136

TH3

U

11

R64

R10

R63

R59

R

12

8

R112

J9

J6

J7

J4

J3

J2

J1

F1

D

5

D31

D

30

D

32

D42

D41

D40

D35

D

36

A

D36

D

17

D16

D

15

D14

J1

1

C34

J5

C

52

C51

C75

C74

C

31

C

38

C27

C26

C25

C1

J12

U

12

+5

V

J

T

S

J 1

Fig. 14

6

J

T

C

S

7

Pre-commissioning

Ensure that the system has been adequately flushed.

Purge gas supply of air and test for soundness.

Carry out final electrical tests to ensure the correct polarity and

earthing continuity.

DHW

Open the main cold feed valve 40.

Open all hot taps to purge DHW system.

Check for water soundness.

Check flow rate at the bath tap is set correctly (see technical data).

Central Heating

Open flow and return valves on the boiler 37 and 41 (Fig. 15)

Open the automatic air vent 18 (Fig. 2)

Fill system and vent radiators.

Set system pressure and remove filling loop.

Check for leaks.

Manually check pump is free to turn.

Switch on electrical supply.

Press the Central Heating switch 29 (Fig. 3) to switch on heating

mode.

Press the +

key

32 (Fig. 3) to set heating temperature to maximum.

Allow pump to run for several minutes.

Isolate the electrical supply.

Drain boiler and check water filter for installation debris.

Replace filter and recharge system.

Lighting the Boiler

Inspect the entire gas supply for soudness, including the gas meter,

the gas installation should be in accordance wiith the relevant

standards, in GB this is BS 6891 and in IE this is the current edition

of I.S.813.

Connect gas pressure gauge to test point 39 (Fig. 15).

Turn on the gas supply and boiler gas tap 39 (Fig. 15).

Ensure electrical supply is on.

Ensure all external controls are calling for heat.

Press on Central Heating switch 29 (Fig. 3) to switch on heating

mode.

Press the +

key

32 (Fig. 3) to set heating temperature to maximum.

The boiler will light. Allow the boiler to heat system.

Check the inlet gas pressure (working pressure) while boiler is

operating in hot water mode.(Refer to technicaldata).

Check the operation of the boiler controls and safety devices.(see

separate servicing leaflet for details).Set the by pass (refer to the

paragraph bellow).

Re-flush the system to remove any dissolved oils and fluxes.

Recharge system pressure and introduce any water treatment as

required.

P

V

P

Fig. 13

Electrical Connections

Commissioning and Testing

Summary of Contents for Centora green 24 Nat

Page 23: ...23 ...