11

7

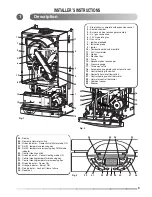

By pass and Pump

The boiler is fitted with a pre-adjusted by pass. Although

adjustment is not normally necessary, the by pass can be reset by

turning screw D (fig. 15 ) anticlockwise to open the by-pass using

the chart below for guidance. If used on a system with thermostatic

radiator valves, the flow rate with the thermostatic valves closed

should be adjusted to at least 300 l/hr. The enclosed charts indicate

the residual head of the pump available for the system. The pump

fitted on the boiler is a double speed model. (GV = High speed and

PV = low speed). The speed setting is described in chapter 9.

Speed selection is only available in C.H. mode.

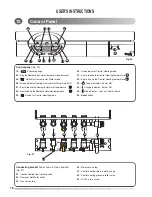

Post Commissioning

Ensure system pressure has been set correctly.

Set all parameters of the boilers as shown in chapter 9

ADJUSTMENTS AND SETTINGS.

Set boiler thermostat and controls.

Set programmer to householder’s requirements.

Set external controls.

Ensure the Logbook is fully completed with your contact details and

required readings and details of the

installation.

Handing Over to the Householder

Demonstrate the lighting and operation of the boiler.

Demonstrate how to maintain the system pressure.

Demonstrate the operation and setting of the built-in clock.

Explain the benefits of annual maintenance by a competent person.

Explain how to register guarantee.

Ensure the Householder countersigns the Log Book to confirm that

these demonstrations have been carried out and understood.

For IE, it is necessary to complete a “Declaration of Conformity” to

indicate compliance to I.S.813. An example of this is given in the

current edition of I.S.813. An example of this is given in the curent

edition of I.S.813. in addition it is necessary to complete the

“Benchmark” Log Book.

T

T

1

2

Fig. 17

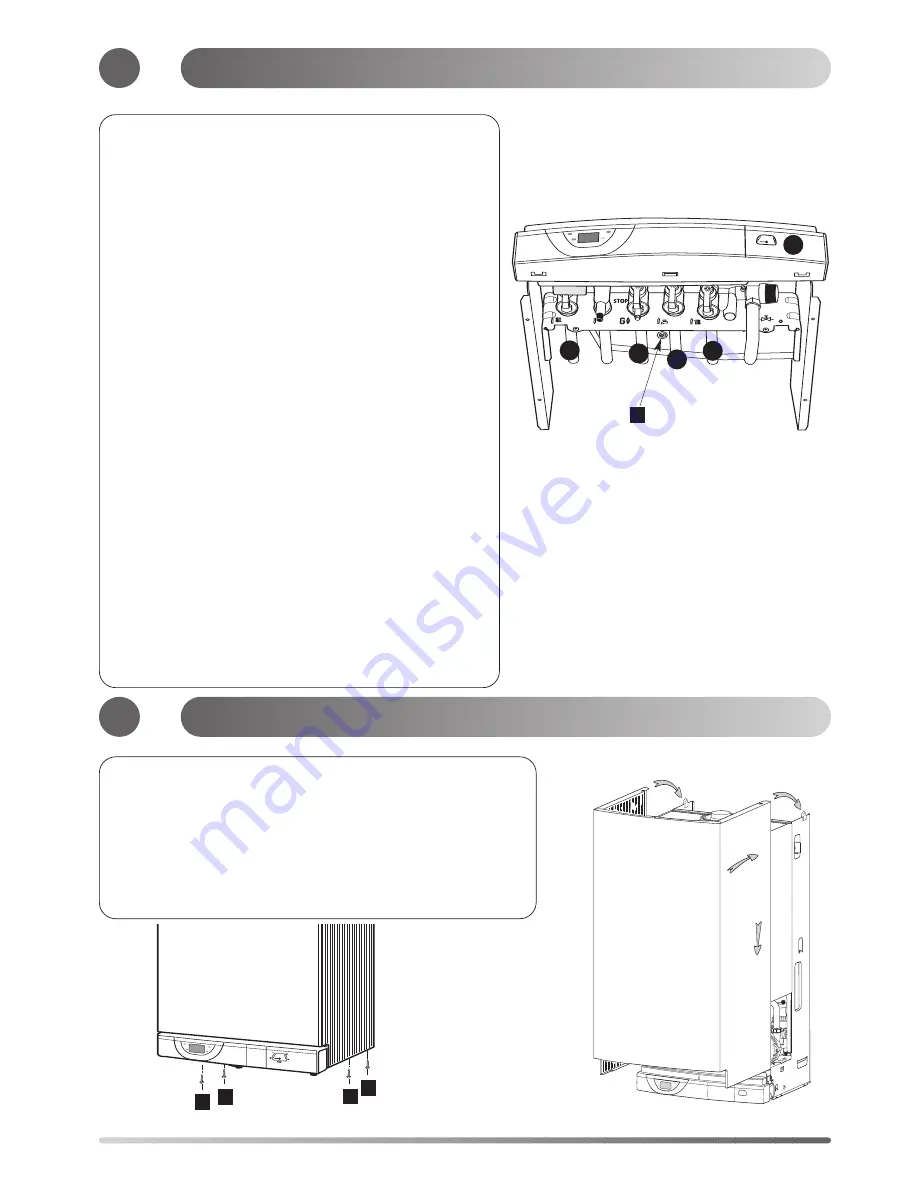

Fitting the casing

Remove the protecting film from the casing :

- Position the casing as shown fig. 17

- Slide down the casing and put the casing holes on the plastic pins

located on the top of the chassis

- Control the correct position of the casing onto the boiler

- Tighten the 4 screws located at the bottom as shown in fig. 16.

8

A A

A

A

Fig.16

bar

0

1

3

4

Fig. 15

D

16

37

39

40

41

Commissioning and Testing

(continued)

Fitting the Casing

Summary of Contents for Centora green 24 Nat

Page 23: ...23 ...