8

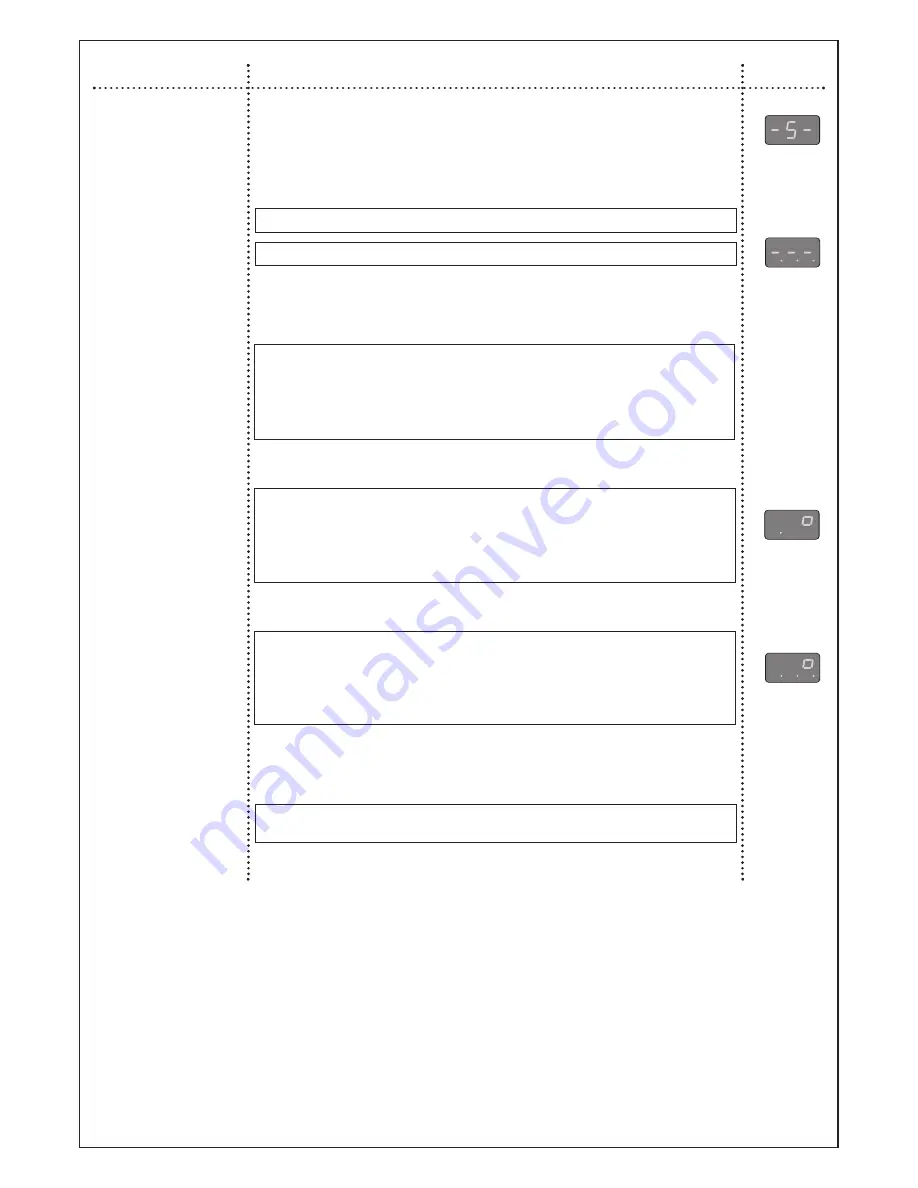

Menu - 5 - Combustion rate control mode

X X

DISPLAY

ACTION

CONFIGURATION

wait 5 ”

Combustion rate control mode OFF

Switching on the combustion rate

control mode. Central heating output

reach the maximum power set in

menu 4 section 9.

Central heating temperature is dis-

played in celsius degrees.

The 3 dots indicate that the combus-

tion rate control is ON at maximum

output.

Switching the combustion rate

down to minimum power.

Central heating temperature is dis-

played in celsius degrees.

The dot indicates that the combus-

tion rate control is ON at minimum

output.

Switching on the combustion rate to

maximum output set in menu 4 sec-

tion 9.

Central heating temperature is dis-

played in celsius degrees.

The 3 dots indicate that the combus-

tion rate control is ON at maximum

output.

X X

Switching off the combustion rate

control mode.

press once

press once

press once

press once

press once

Effect

Display

Locking conditions of the combustion rate control mode :

- boiler in stand by mode

- D.H.W. draw off

- room thermostat is not calling for heat

- room thermostat is calling for heat but the maximum temperature is reached

- boiler in lockout mode

- after a reset or if the main supply fails

- end of the mode if operator leave menu 5

- after 15 minutes if there is no actions on keyboard

Nota :

As soon as the combustion rate control mode is on, Central Heating and Domestic Hot Water keys

are inactive.