Model 4030

Installation, Operation and Maintenance

2

Rev. 5/22/2019

4030-IOM-A.doc

G

ENERAL

S

PECIFICATIONS

M

ODEL

:

4030[E

OR

X]

[A

OR

F]

[O

OR

X]

[

LENGTH

)

]

[

ALIGN OR FLAT DECK

]

[

OPEN OR CLOSED FRONT

]

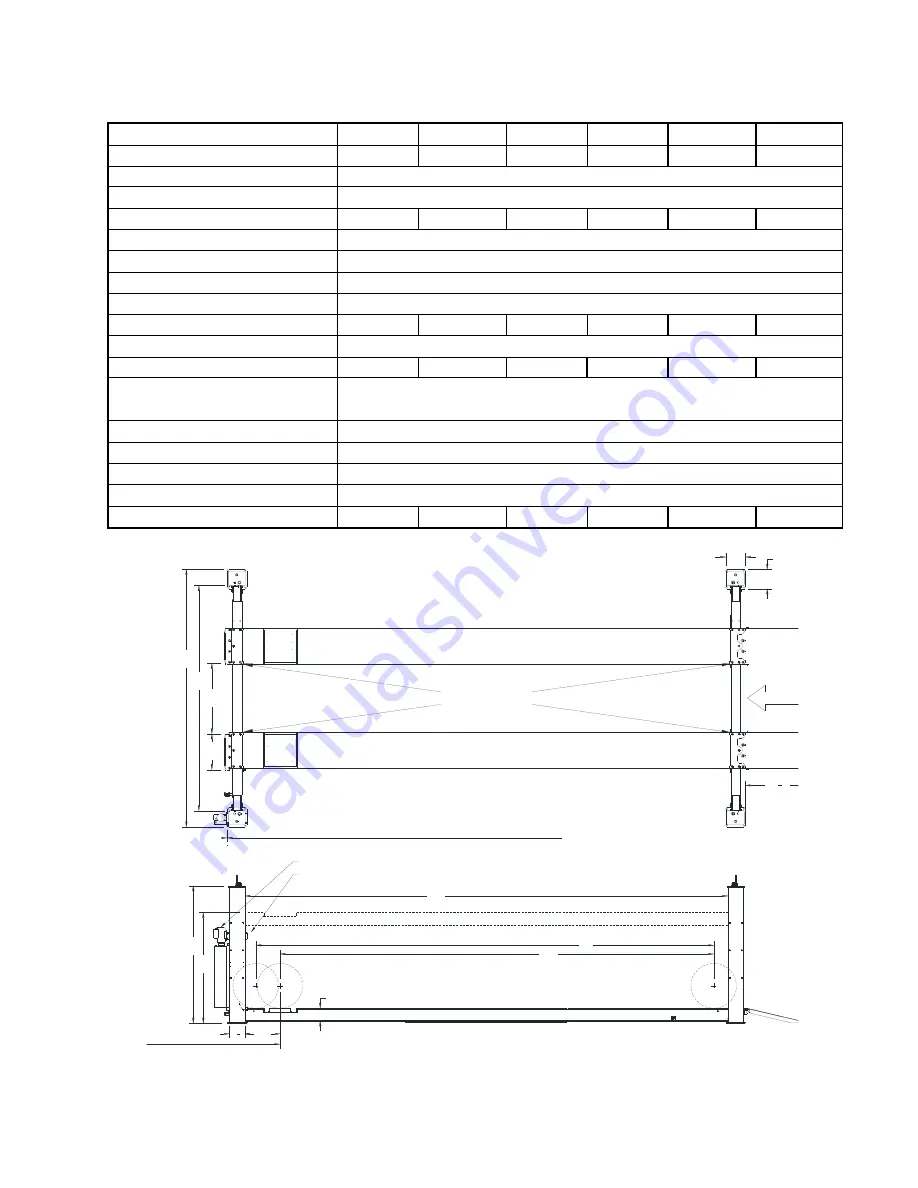

SPECIFICATIONS

4030SFX

4030EFX

4030XFX

4030SAX

4030EAX

4030XAX

A

Length Overall

308” 344” 380”

308” 344” 380”

B

Width Overall

172.75”

C

Inside Columns

152”

D

Between Columns

246” 282.5”

318.5”

246.5” 282.5” 318.5”

E

Height of Columns

92.25

”

F

Height of Runways

8.5

”

G

Width of Runways

24"

H

Width Between Runways

46” & 52"

I

Maximum Wheelbase *

244.5

”

281

”

317

”

244.5

”

281

”

317

”

J

Rise Height

71.75"

K

Max. 2 Wheel Alignment

N/A N/A N/A

219.5"

256" 292

Lifting Capacity

(Hydraulic Pressure at Cap.)

30,000 lbs.

(2190 psi)

Air Supply Required

90-120 psi Clean & Dry

Motor

3HP

Voltage (Single Phase Std.)

230v

Rise Time

126 Seconds

(approximate)

Min. Recommended Bay Size

28' x 17'

31' x 17'

34' x 17'

28' x 17'

31' x 17'

34' x 17'

* Maximum wheelbase is based on a tire diameter of 30”

A

38

3

4

"

2' MIN. TO NEAREST

OBSTRUCTION FOR

ON-ALIGNMENT LIFTS

FRO

N

T

REA

R

DRIVE ON

IDLER RUNWAY

POWER RUNWAY

13"

BASE PLATE

13"

DIAGONALS TO BE WITHIN 1/4"

H

C

B

G

J

E

K

I

23"

10

1

2

"

D

F

POWER UNIT

OPTIONAL POWER UNIT LOCATION

SEE NOTE

NOTE: IF USING THIS LIFT IN CONJUNCTION WITH AN ALIGNMENT SYSTEM, CONSULT ALIGNER'S

MANUAL FOR MANUFACTURER'S MINIMUM RECOMMENDED DISTANCE TO FRONT TURN PLATE AND

ADJUST THIS DIMENSION ACCORDINGLY.

Fig 1 – General Specifications and Service Bay Layout