25

M

AINTENANCE

/

I

NSPECTION

S

CHEDULE

Periodically check the electrical safety devices and report any faults to the Challenger Lifts Technical Support.

-To avoid personal injury, permit only qualified personnel to perform maintenance on this equipment. Maintenance personnel should follow lockout/tagout

instructions per ANSI Z244.1.

-The following maintenance points are suggested as the basis of a routine maintenance program. The actual maintenance program should be tailored to the

installation. See ANSI/ALI ALOIM booklet for periodic inspection checklist and maintenance log sheet.

-Replace all Safety, Warning or Caution Labels if missing or damaged (

See page 8.

)

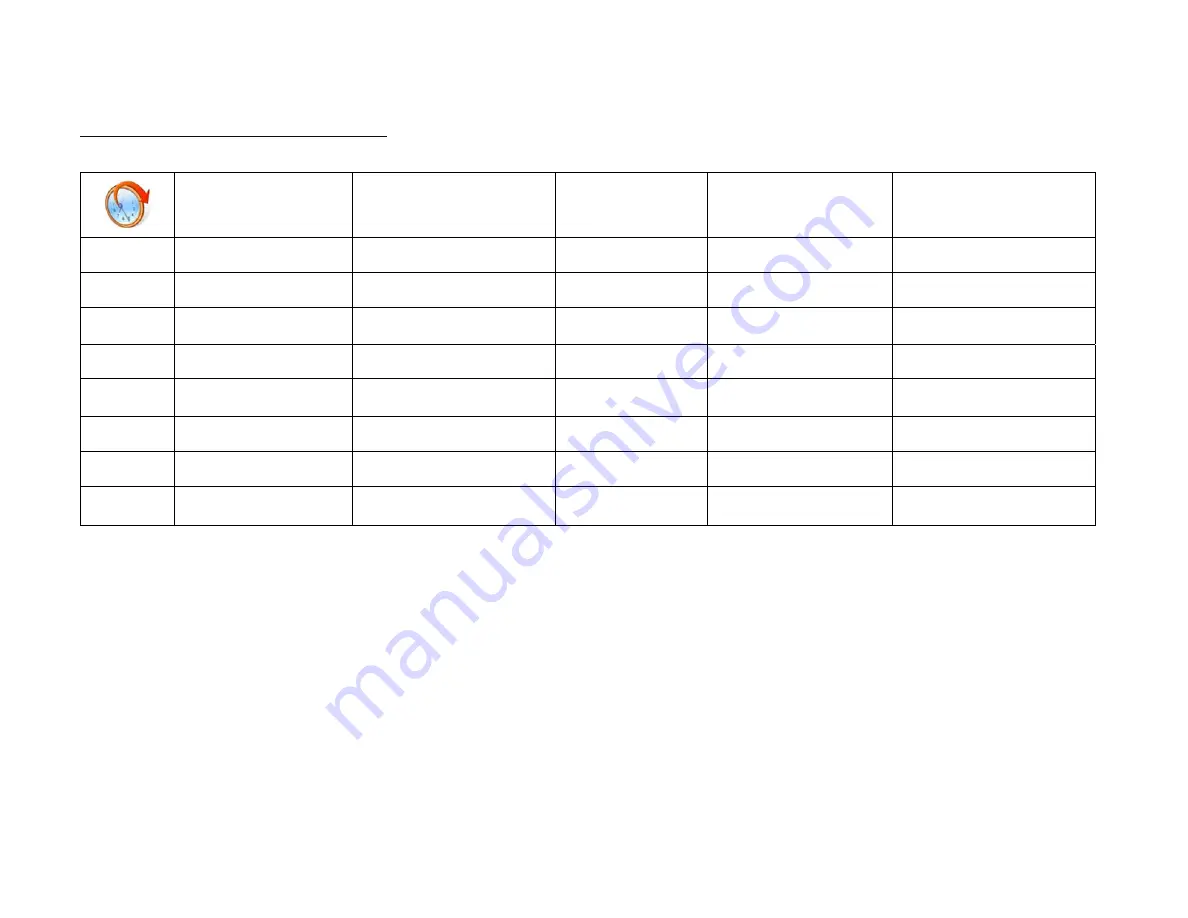

WHAT WHERE

MACHINE

STATUS

HOW

USE

Daily

SYNCHRONIZATION PLATFORMS

IN

MOTION VISUAL

INSPECTION SYNC

PROCEDURE

Daily

MECHANICAL LOCKS

UNDER PLATFORMS

IN MOTION

VISUAL INSPECTION

Weekly

PHOTOCELL

REAR END OF

PLATFORM

IN MOTION

VISUAL INSPECTION

See “PHOTOCELL”

Weekly

AIR CONNECTIONS

PNEUMATIC CIRCUIT

IN MOTION

VISUAL INSPECTION

Weekly

HYDRAULIC

CONNECTIONS

HYDRAULIC CIRCUIT

FULLY RAISED

VISUAL INSPECTION

Bi-Weekly

SLIDE BLOCKS

BASES & PLATFORMS

FULLY RAISED

GREASE

MOLYCOTE G-4700

Bi-Weekly

PINS AND SUPPORTS

STRUCTURE

OFF

GREASE

MOLYCOTE G-4700

Annually

TANK HYDRAULIC

UNIT

OFF OIL

CHANGE

AGIP LH 46

ESSO OSO H 46

Summary of Contents for SX14

Page 4: ...4 LIFT BASE LAYOUT Fig 2 Base Layout PIT LAYOUT Fig 3 Pit Details...

Page 9: ...9...

Page 10: ...10 CONTROL UNIT 34 5 16 3 17 4 2 28 14 12 27 26 26 29 31 30 35...

Page 11: ...11 LABEL 2 LABEL 2A LABEL 3 LABEL 3A LABEL 4 LABEL 4A LABEL 5 LABEL 5A...

Page 12: ...12 LABEL 12 LABEL 14 LABEL 14A LABEL 16 LABEL 17...

Page 13: ...13 LABEL 22 LABEL 23 LABEL 25 LABEL 26 LABEL 27 LABEL 28 CHALLENGER SERIAL TAG LABEL 29...

Page 14: ...14 LABEL 30 LABEL 31 LABEL 34 LABEL 35 LABEL 35A...

Page 22: ...22 AIR SWITCH BASE SETTING...

Page 26: ...26 LUBRICATION POINTS repeat symmetrically on both sides of the lift...

Page 30: ...30 Fig 13 Electrical Wiring Diagram Console Lid Switches...

Page 31: ...31 Fig 13 Electrical Wiring Diagram Continued...

Page 32: ...32 Fig 14 Hydraulic Diagram...

Page 33: ...33 Fig 15 Pneumatic Diagram...

Page 34: ...34 PARTS BREAKDOWN 11 16 10 12 10 9 7 8 6 5 2 1 4 3 13 12 15 14...

Page 36: ...36 7 12 14 5 3 4 16 6 10 9 11 15 8 17 17 13 18 2 19 20 21 1 350 BAR 110 BAR...

Page 38: ...38 1 4 5 9 11 12 18 15 13 20 23 22 21 24 6 2 14 25 16 26 3 8 3 7 10...

Page 40: ...40 26 42 24 44 43 47 48 49 50 25 42 43 27 28 30 31 32 29...

Page 42: ...42...

Page 44: ...44 29 48 47 21...