28

M

ANUAL

L

OWERING

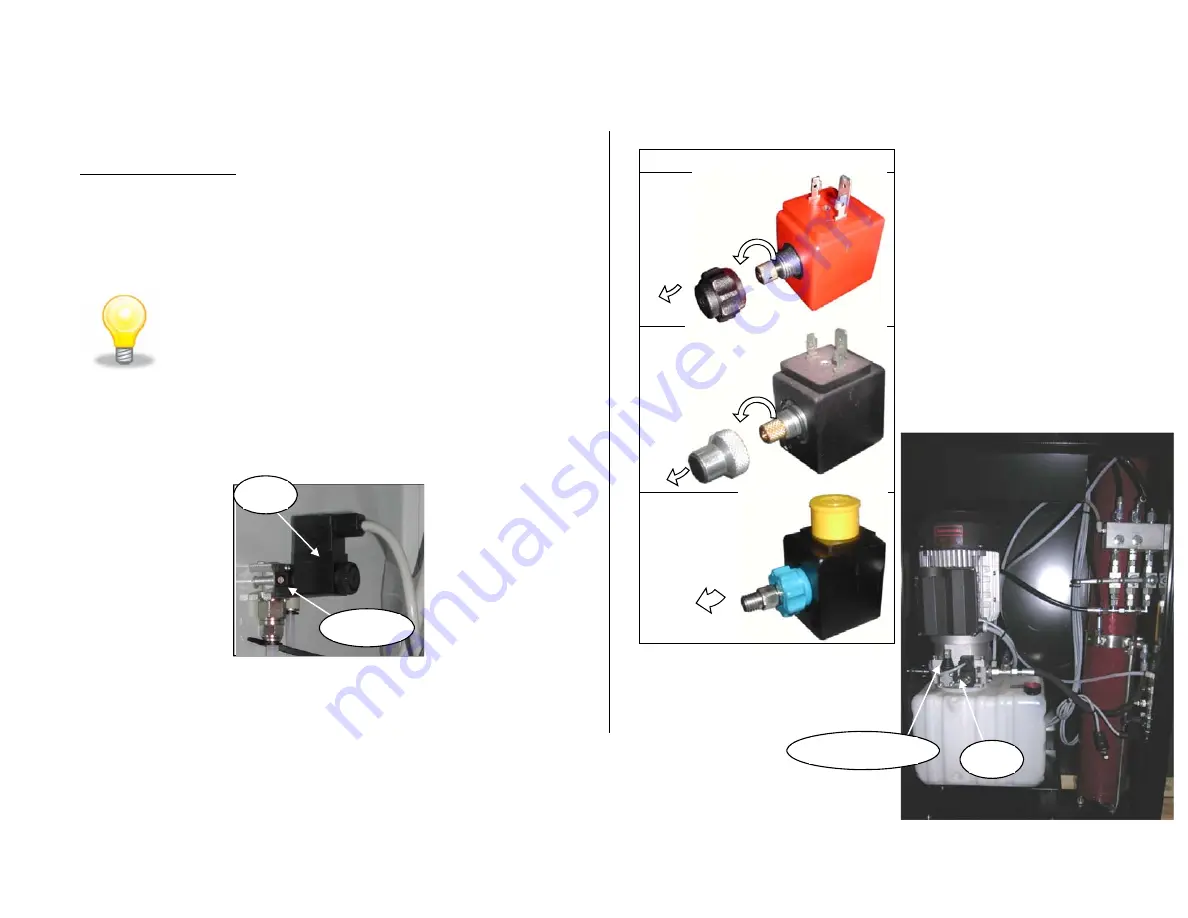

Operations to be performed to lower raised platform in the event of

loss of power to equipment:

Using pump handle, pump until the mechanical locks

are no longer engaged.

Activate Lock Release using the dedicated manual

valve on solenoid valve EV2 (turn screw 90°).

ENSURE THAT MECHANICAL LOCKS ARE OPEN.

Activate solenoid valve EV1 (see photograph:

A

or

B

or

C

) and

allow the lift to lower;

to restore, return the manual command of valve EV2 to its position

and tighten the knurled pins.

EV1

EV2

SCREW

A

B

C

Manual Pump

EV1

Summary of Contents for SX14

Page 4: ...4 LIFT BASE LAYOUT Fig 2 Base Layout PIT LAYOUT Fig 3 Pit Details...

Page 9: ...9...

Page 10: ...10 CONTROL UNIT 34 5 16 3 17 4 2 28 14 12 27 26 26 29 31 30 35...

Page 11: ...11 LABEL 2 LABEL 2A LABEL 3 LABEL 3A LABEL 4 LABEL 4A LABEL 5 LABEL 5A...

Page 12: ...12 LABEL 12 LABEL 14 LABEL 14A LABEL 16 LABEL 17...

Page 13: ...13 LABEL 22 LABEL 23 LABEL 25 LABEL 26 LABEL 27 LABEL 28 CHALLENGER SERIAL TAG LABEL 29...

Page 14: ...14 LABEL 30 LABEL 31 LABEL 34 LABEL 35 LABEL 35A...

Page 22: ...22 AIR SWITCH BASE SETTING...

Page 26: ...26 LUBRICATION POINTS repeat symmetrically on both sides of the lift...

Page 30: ...30 Fig 13 Electrical Wiring Diagram Console Lid Switches...

Page 31: ...31 Fig 13 Electrical Wiring Diagram Continued...

Page 32: ...32 Fig 14 Hydraulic Diagram...

Page 33: ...33 Fig 15 Pneumatic Diagram...

Page 34: ...34 PARTS BREAKDOWN 11 16 10 12 10 9 7 8 6 5 2 1 4 3 13 12 15 14...

Page 36: ...36 7 12 14 5 3 4 16 6 10 9 11 15 8 17 17 13 18 2 19 20 21 1 350 BAR 110 BAR...

Page 38: ...38 1 4 5 9 11 12 18 15 13 20 23 22 21 24 6 2 14 25 16 26 3 8 3 7 10...

Page 40: ...40 26 42 24 44 43 47 48 49 50 25 42 43 27 28 30 31 32 29...

Page 42: ...42...

Page 44: ...44 29 48 47 21...