www.jbstools.com

www.jbstools.com

www.jbstools.com

9

9

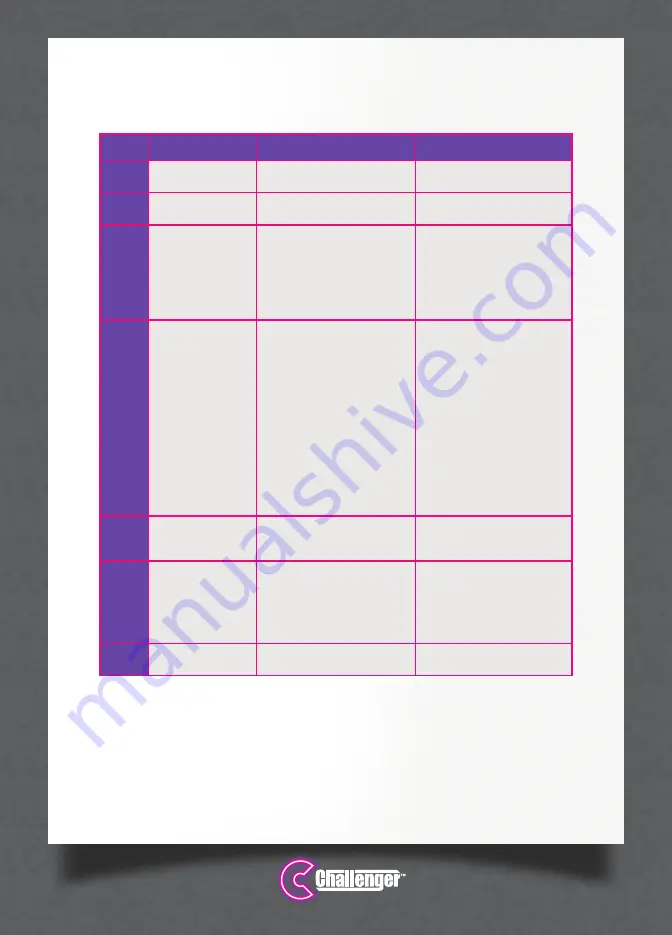

TROUBLE SHOOTING

No.

Fault

Cause

Countermeasures

1

The forks cannot

reach the max. height

•

Low hydraulic oil level

•

Inject hydraulic oil

2

The forks cannot be

raised

•

No hydraulic oil

•

Hydraulic oil is impure

•

Check hydraulic oil

•

Replace the hydraulic oil

3

Pump station motor

cannot run

•

Emergency button is not

switched on

•

Low voltage of the storage

battery

•

Wiring terminal of the power

line is loose

•

Motor contactor is damaged

•

Turn the emergency button

clockwise

•

Charge the battery

•

Fasten the wiring terminal

•

Replace the parts

•

Contact you distributor

4

The forks will not

lower

•

Uneven centre of gravity

of goods or overloading

causes deformation of the

large piston rod or the oil

tank body

•

The forks are rusted

and hard to move due to

long-term exposure to air

when the platform stays in

the higher position for an

extended period of time

•

The release valve of the

hydraulic pump station is

worn or damaged and thus

cannot be opened

•

Replace the large piston

rod or the oil tank body

•

Lower the forks to the

lowest position when not

using the crane and make

sure to lubricate the piston

rods

•

Replace the release valve

of the pump station

•

Contact you distributor

5

Oil leakage

•

Sealing parts are aged or

damaged

•

Some parts are broken

•

Replace the parts

•

Replace the parts

•

Contact you distributor

6

Forks lower itself

•

The relief valve is unable to

be shut tightly due to impure

hydraulic oil

•

Sealing parts are aged or

damaged

•

Release valve is damaged

•

Replace the hydraulic oil

•

Replace the parts

•

Replace the parts

•

Contact you distributor

7

Storage battery

cannot be charged

•

Storage battery is damaged

•

Charging plug is loose

•

Replace the parts

•

Check connections

Summary of Contents for EPS0412

Page 2: ...www jbstools com 2 WWW CHALLENGERHOISTS COM AU ...

Page 4: ...www jbstools com 4 WWW CHALLENGERHOISTS COM AU SPECIFICATIONS ...

Page 12: ...www jbstools com 12 WWW CHALLENGERHOISTS COM AU SPARE PARTS ...

Page 14: ...www jbstools com 14 WWW CHALLENGERHOISTS COM AU SPARE PARTS ...

Page 16: ...www jbstools com 16 WWW CHALLENGERHOISTS COM AU SPARE PARTS ...

Page 18: ...www jbstools com 18 WWW CHALLENGERHOISTS COM AU SPARE PARTS ...

Page 20: ......