GENERAL INFORMATION - A-15

79019435B

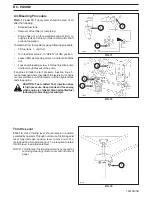

TORQUE CHART FOR INCH FASTENERS (ZINC COATED)

Nominal

Size

Strength Class-

SAE 2 (plain head)

Strength Class-

SAE 5

Strength Class-

in Inches (SAE 8)

Torque Nm (lbf ft)

Torque Nm (lbf ft)

Torque Nm (lbf ft)

Min. Max. Min.

Max.

Min.

Max.

1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

1

1-1/8

1-1/4

1-1/2

6.8 (5)

13.5 (10)

24 (18)

41 (30)

61 (45)

122 (90)

217 (160)

-

-

-

-

-

8.1 (6)

16.2 (12)

28 (21)

46 (34)

70 (52)

142 (105)

250 (185)

-

-

-

-

-

10.8 (8)

22 (16)

39 (29)

64 (47)

99 (73)

198 (146)

350 (258)

569 (420)

847 (625)

1051 (775)

1491 (1100)

2576 (1900)

15 (11)

30 (22)

53 (39)

85 (63)

131 (97)

263 (194)

464 (342)

759 (560)

1119 (825)

1390 (1025)

1966 (1450)

3390 (2500)

16.2 (12)

31 (23)

56 (41)

91 (67)

140 (103)

279 (206)

495 (365)

800 (590)

1200 (885)

1681 (1240)

2386 (1760)

4121 (3040)

21.7 (16)

42 (31)

75 (55)

121 (89)

185 (137)

371 (274)

658 (485)

1071 (790)

1580 (1165)

2224 (1640)

3159 (2330)

5437 (4010)

TORQUE CHART FOR METRIC FASTENERS (ZINC COATED)

Nominal

Size

Strength Class-

ISO 4.6 (4T)

Strength Class-

ISO 8.8 (7T)

Strength Class-

ISO 10.9 (9T)

in mm

Torque Nm (lbf ft)

Torque Nm (lbf ft)

Torque Nm (lbf ft)

Min. Max. Min.

Max.

Min.

Max.

M3

M4

M5

M6

M8

M10

M12

M16

M20

M24

M30

M36

0.5 (0.3)

1.2 (0.9)

2.2 (1.6)

4.0 (2.9)

9.5 (7.0)

19 (14)

33 (24)

84 (62)

160 (118)

280 (207)

540 (398)

950 (700)

0.7 (0.5)

1.6 (1.2)

3.0 (2.2)

5.0 (3.7)

12.5 (9.2)

25 (18)

43 (32)

110 (81)

210 (155)

360 (266)

720 (531)

1250 (922)

1.3 (0.9)

3.1 (2.3)

6.0 (4.4)

10 (7.4)

25 (18.4)

50 (37)

90 (66)

200 (148)

420 (310)

720 (531)

1400 (1033)

2500 (1844)

1.7 (1.3)

4.1 (3.0)

8.0 (5.9)

14 (10.3)

35 (26)

70 (52)

120 (89)

260 (192)

560 (413)

860 (634)

1800 (1328)

3300 (2434)

1.8 (1.3)

4.3 (3.2)

8.5 (6.3)

14 (10.3)

36 (26)

72 (53)

120 (89)

300 (221)

600 (443)

1000 (738)

2100 (1549)

3600 (2655)

2.4 (1.8)

5.7 (4.2)

1.5 (8.5)

20 (14.8)

46 (34)

96 (71)

160 (118)

40 (295)

800 (590)

1300 (959)

2800 (2065)

4800 (3540)

STANDARD TORQUE CHART

NOTE: Above torques are for “rigid” joints, or joints meet-

ing the following conditions:

1. Damage will not occur to joined members of

an assembly.

2. It is desirable to use a higher clamping force.

3. Fastener threads are NOT lubricated prior to

assembly.

The following conditions will require a torque value differ-

ent than stated above:

1.

Reduced torque required; non-parallel clamping sur-

faces, thick or highly compressible gaskets are used,

or when a higher torque may damage joined assem-

blies.

2.

Clip nuts, weld nuts, self-tapping hardware, or any

condition that causes reduced thread engagement will

warrant a torque less than stated above.

3.

Special torque values, stated in this manual, must

be strictly adhered to as stated in the specific opera-

tion.

NOTE: A number of special torques are used in assem-

bly of tractors. See list.