I-MICN-01.doc

Issue

06

Mar10

5

IOM –

MICRONEX - ZONE 2

FLOODLIGHT (ATEX, Ex n)

supplies should be sought from

the Technical Department.

3.4

Lamps

The Micronex uses double

ended HPS and MBI lamps and

are of a standardised type, with

no preference between make or

colour. All have RX7 caps.

Care must be taken to fit the

correct new and replacement

lamp in order to preserve the

certification conditions and

obtain the designed

photometric performance.

The

lamp type is shown on the

rating plate

. Lamps should be

replaced shortly after they do

not light.

One indication of the

end of life for HPS lamps is

'cycling', where the lamp goes

out then re-ignites after a

minute or so interval. If

discharge luminaires are

burned continuously, they

should be switched off

occasionally to allow old lamps

to fail to re-ignite, rather than

possibly become diodes with

detrimental effects to control

gear.

The above information is

current at the time of

preparation. The development

of lamps and control gear is

ongoing and detailed advice on

lamp performance can be

obtained from the lamp supplier

or from Chalmit.

Note:

HPS and MBI

circuits should not be energised

without a lamp fitted. HPS and

MBI lamps with

internal

ignitors must not be used.

3.5

Mounting

Luminaires should be installed

where access for maintenance

is practical and in accordance

with any lighting design

information provided for the

installation. The stirrup

mounting arrangements should

be secured with lock washers

or self-locking nuts and bolts.

There are clearance holes for

M10 bolts. The luminaire

should be mounted with the

lamp axis horizontal.

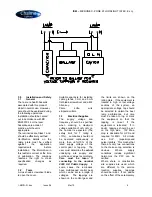

3.5.1 Weights

and

Windages

The weights and windages for

the various floodlight types are

outlined in TABLE 4.

3.6

Cabling and Cable

Glands

3.6.1 Cables

The cable entry temperatures

are given as the rise over the

maximum rated ambient. This

allows the user to adjust the

cable specification for the

actual site maximum

temperature. The terminals are

suitable for standard conductor

section up to 6mm² max. All

models are suitable for looping.

Standard 300/500V cable is

suitable. The cable makeup

must be suitable to ensure the

obtaining of a restricted

breathing enclosure when the

cable gland assembly is fitted.

It is strongly advisable to use a

high quality and well filled cable

with direct entry into restricted

breathing luminaires.

3.6.2 Cable Glands

Cable glands and sealing plugs

when installed must maintain

the restricted breathing

enclosure. Entries suitable for

M20 cable glands are standard.

To maintain the restricted

breathing properties of the

enclosure a suitable cable

gland such as a Hawke

501/453/RAC type should be

installed or a cable gland

satisfying the following

requirements:

The cable gland must

satisfy the requirements for

en 60079-0 and must

maintain an ingress rating

of at least IP65.

The certified cable gland is

to be a compression type

gland where the cable

sheath is evenly

compressed when

tightened or an Ex d

stuffing type or a punched

seal type.

To enable a reliable seal at

the cable entry face a

neoprene or silicone

rubber washer and a

stainless steel washer are

provided for each entry

and must be fitted.

3.7

Cabling and Fitting

Lamps

Access for cabling and fitting

lamps is by removing the front

cover. The cover is released by

undoing the two screws using a

screwdriver. Reselect the

voltage tappings if necessary.

Install the conductors in the

appropriate terminals. Take

care not to cut back the

insulation excessively, 1mm

bare conductor outside the

terminal is a maximum. Any

unused terminal should be fully

tightened.

When the cabling is complete,

make a final tightness and

connection check.

Lamps must be of the correct

type and correctly in place. The

cover is replaced and the

screws tightened down.

3.8

Inspection and

Maintenance

Visual inspection should be

carried out at a minimum of 12

monthly intervals and more

frequently if conditions are

severe. The time between

lamp changes could be very

infrequent and this is too long a

period without inspection.

3.8.1 Routine Examination

(a)

The equipment must be de-

energised before opening.

Individual organisations will

have their own procedures.

What follows are guidelines

based on

BS EN 60079-17

and

on our experience :

1.

Ensure the lamp is lit

when energised and