CARE OF THE OPENER

When properly installed, opener will provide high

performance with a minimum of maintenance. The opener

does not require additional lubrication.

Most complaints of unsatisfactory opener operation can

be traced to problems with the door itself. When operated

manually, a properly balanced door will stay in any point

of travel while being supported entirely by its springs.

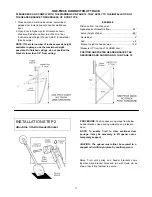

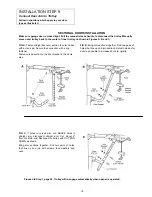

CHAIN TENSION ADJUSTMENT: After installation of the

opener and adjustment of forces and limits, the chain may

appear loose. This is normal.

TO CHECK THE CHAIN TENSION: Disconnect the trolley

by pulling the red handle. If the chain returns to the

position described and illustrated in Step 3 page 9, DO

NOT make ANY further adjustments.

THE OPENER IS NOT INTENDED TO CORRECT ANY

PROBLEMS THAT ARE CAUSED BY AN UNBALANCED

OR BINDING DOOR, BROKEN DOOR SPRINGS OR BY

FAULTY DOOR HARDWARE.

REMOTE CONTROL TRANSMITTER: The portable

remote control may be secured to a car sun visor with the

clip provided. Additional remotes can be purchased at any

time for use in all vehicles using garage. Refer to

Accessories on page 4.

Any new remotes must be set to the same code as the

original remote. Code setting procedures are described on

page 23.

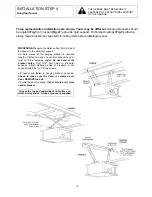

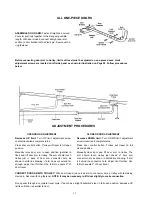

LIMIT AND FORCE ADJUSTMENTS: These adjustments

must be checked and properly set when opener is installed.

Only a screwdriver is required. Pages 20 and 21 refer to the

limit and force adjustments. Follow the instructions carefully.

REMOTE CONTROL BATTERY: The 12 Volt battery

should produce power for at least one year. As long as

there is adequate power, the transmitter battery test light

will glow when the push button is pressed (and the opener

will operate). When the light becomes dim or does not

come on, replace the battery. If transmission range

lessens, check the battery test light.

TO CHANGE BATTERY: Slide the battery compartment

cover back. Discard the old battery and Position the new

battery as indicated on the case.

REPEAT THE SAFETY REVERSE TEST AFTER ANY

ADJUSTMENT. Weather conditions may cause some

minor changes in the door operation, requiring some

readjustments, particularly during the first year of

operation.

THE SAFETY REVERSE SYSTEM IS IMPORTANT (SEE

GARAGE DOOR MUST REVERSE ON CONTACT WITH

A 1-lNCH OBSTACLE PLACED ON THE FLOOR.

FAILURE TO PROPERLY ADJUST OPENER MAY

RESULT IN SERIOUS PERSONAL INJURY FROM A

CLOSING GARAGE DOOR.

MAINTENANCE OF YOUR OPENER

TWICE A YEAR

MANUALLY OPERATED DOOR. If it is unbalanced or

binding, call for professional garage door service.

CHECK TO BE SURE DOOR OPENS & CLOSES FULLY.

Adjust Limits and/or Force if necessary.

REPEAT SAFETY REVERSE TEST. Make any necessary

adjustments (See Page 22).

CHECK CHAIN TENSION. Adjust if necessary.

ONCE A YEAR

OIL DOOR ROLLERS, BEARINGS AND HINGES.

ONCE A MONTH

7

Summary of Contents for 1145-1/3HP

Page 5: ...5...