3-en

MICRO SWITCHES

The micro switches installed on the inside of the ART300XXX (24V) are

not meant as limit switches, if the CB24 and CB124 controls are used.

They generate a pulse for the control.

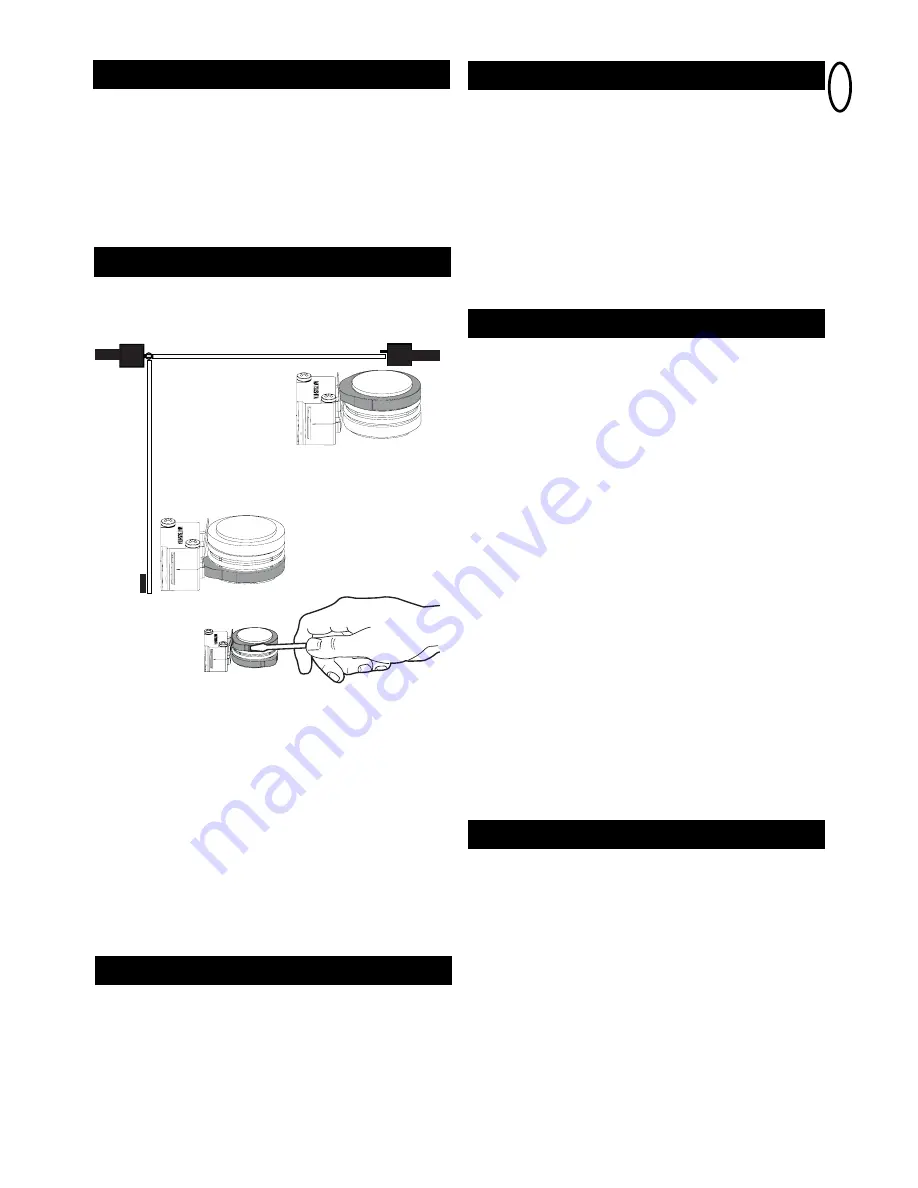

Adjustment:

The two superposed cams activating the micro switches

are to be adjusted in a way that they trigger between the open position

and the closed position. The cams are not especially assigned for open

or closed position.

The correct adjustment can be checked very easily when the operator is

disengaged. The micro switches make a “clicking sound” when

triggered.

Using a flat screwdriver, adjust the cams so that one cam triggers

approximately in the first third, the other one approximately in the last

third of the gate movement. (see illustration)

Having a problem?

Both cams are triggered at once.

In this case the travel cannot be set and the control flashes.

Remedy: Enlarge distance between cams.

Operator does not accept travel.

Remedy: Are both micro switches triggered correctly as described?

In this case, check if motorcabel is interchanged.

SAFETY MEASURES

A WING GATE OPENER SHOULD ALWAYS BE OPERATED IN

CONJUNCTION WITH CONTACT STRIPS AND / OR LIGHT

BARRIERS AS SAFETY FEATURES.

Please ensure that you comply with the standards, regulations and

safety devices applicable to your particular case.

Should the force generated by the moving wing at its

closing edge exceed 400 N, additional safety features must

be fitted suitable for the application.

FINAL REMARKS

Arrange the handover of the wing gate opener with your customer Make

sure that persons will operate the gate are familiar with its functions and

can operate them without problems. Have your customer practice

operating the gate until he is fully acquainted with all the following:

• Main switch.

• Rules of operation (e.g. do not drive through while the gate is still

opening).

• Additional safety features (photoelectric barrier, contact strip, flashing

lights, etc.).

• Switch to manual operation in case of power failure.

• Provide the customer with a full set of instructions. Inform him to keep

them in a safe place and read them when possible.

• Reference a checklist, so that you have a record of which functions

have been explained and of any points not dealt with.

ACCESSORIES

Model 94335E

3-channel mini transmitter, 433.92MHz

Model 9747E

Keypad, 433.92MHz

Model 760E

Key switch

Model 100027

1-Function Keyswitch, surface mount

(Flush mount - 100010)

Model 100041

2-Function Keyswitch, surface mount

(Flush mount - 100034)

Model 100263

Infrared barrier

Model 203285

E-Lock 12 Volt

Model 203292

Loop Detector 1 Channel

Model 203308

Loop Detector 2 Channel

Model 203315

Standard Hardstop

Model 203322

Hard Stop High

Model 203339

Mechanical Floor Lock for Double Wings

Model 600008

IR Sensor Stand - 530mm

Model 600015

Key Switch Stand - 1100mm

Model 600046

2.5 Safety Edge Set (Small)

Model 600053

20m Bulk Pack Safety Edge Profile (Small)

Model 600060

Assembly Pack Safety Edge (Small)

Model 600077

Bulk pack (not shown)

Model 600091

Main switch

Model 600138

20m Bulk Pack Safety Edge Profile (Medium)

Model 600145

20m Bulk Pack Safety Edge Profile (Large)

Model 600152

Assembly Pack Safety Edge

(Medium/Large)

Model 600169

1m (3.2 ft.) Safety Edge Profile (Medium)

Model 600176

1m (3.2 ft.) Safety Edge Profile (Large)

Model 600213

Interface Box for Safety Edges

TECHNICAL DATA

Modell

ART300XXX (24V)

Voltage in

230V AC/24AC/24VDC

Voltage out (Motor)

24VDC

Power

60W

Current (max)

2,5A

Current (no load current)

0,3A

Torque

280Nm

Motor speed

1800rpm

Duty cycle (max)

50 cycles/h

Working temperature range

deg C -20°C/+55°C

Protection class

I

Degree of protection

IP44

Weight

9Kg

Max. gate wing lenght

2,5m

Max. gate weight at max. wing lenght

300Kg

incl. 20% reserve

GATE FITTING

For steel gates, fixings should be welded on or through bolted. When

through bolting the gate, use large washers or a plate on the other side.

The drive mechanism exerts an extremely high force on this joint.

Fixings must be through bolted for wooden gates. Wood deflects under

load and the bolt will become loose. Due to movement caused by

repeated loading, the wood deflects more and more until the gate no

longer closes correctly and has to be repaired.

The arm should not be mounted while fully extended

(see Fig. 4).

The

drive is self-locking. Mount the drive provisionally (e.g. with finger-tight

thumb-screws), and check the mounting position by opening the gate

manually.

Closed position

Open position

Gate closed

Gate open

Summary of Contents for ART300 series

Page 23: ...ART 1 ART 2 ART 3 ART 6 ART 7 115 o 90 o 90 o 90 o 115 o 115 o 115 o 90 o 1 A B 2 3 A...

Page 25: ...6 7 8 9 A B 10 11 A B C D...

Page 26: ...ART 6 ART 7 41ABSC 5 41ASWG 454 41AART 63 ART 3AL 41AART 1022SA 41AART 1026SA 13 12...

Page 27: ......

Page 28: ...709446D 2010...

Page 234: ......

Page 235: ......