15/16 en

INDICATION OF THE DIAGNOSIS LED

The LED diagnostics show the

fi

rst upcoming issue. If several issues are existing the LED diagnostics may not show them.

Indication

1x blinking

2x blinking

3x blinking

4x blinking

5x blinking

6x blinking

7x blinking

8x blinking

9x blinking

10x blinking

11x blinking

12x blinking

13x blinking

14x blinking

15x blinking

Description

Motor 1 has insuf

fi

cient connection to control board

Control board does not see motor sensor.

Travel distance programming was not successful

Motor 2 has insuf

fi

cient connection to control board

Limits for motor 2 have not been accepted

A: After or during programming travel: Wing 1 did not

open wide enough and did not meet the integrated

passpoint which is located inside the operator half-

way above the spindle.

B: Motorcables have insuf

fi

cient connection to contol

board

Yellow or white cable not wired or badly connected

Limits for motor 1 have not been accepted

Travel has not been programmed

The process of programming has been interrupted

Force to operate the gate is too high

A: Gate is out of order

B: Gate is rough-running

C: Gate stopped through windload

D: Wrong mechanical installation

Photocells 1 block instal LED PHO1 =OFF

A: Object blocks photocells

B: Alignment of the sensors is incorrect

C: Power supply to photocells is insuf

fi

cient

Photocells 2 block installation

Photocells 3 block installation

Emergency stop switch blocks installation

Safety edge blocks installation

A: Object obstructs safety edge

B: Defective safety edge

C: Power too low or broken wire in supply

Power supply to control board is too low

A: Defective supply 230V or malfunctioning contact

B: Broken wire in supply cable (copper cable)

C: The battery (accessory) to operate the gate whilst

power failure is dead.

EEPROM Fault

Power up failed

Only LYN/SCS

Release lever OPEN

Defect on relay or major electrical component

A: Overload

B: Bad wiring (wrong)

C: water in photocells (bad installation)

D: a photocell was connected before but not removed

(disconnected)

Remedy

Cables not wired or badly connected.

Check terminals precisely. Consider wire lengths

The gate must be closed completely before programming the

travel distance

Refer to 1x blinking

A: Open gate wide enough when programming the travel (50%

over maximum)

B: Check terminals precisely. Consider wire lengths

C: See 1x blinking (wiring)

Refer to 3x blinking

The gate must be closed completely before programming the

travel distance.

Refer to 5x blinking also

A: Repair gate

B: Check if gate can be easily moved

C: Do not operate gate in very windy conditions

D: Reprogram to achieve suf

fi

cient level of force

A: Remove object

B: Check alignment

C: Check cable widths and contacts

Refer to 7x blinking

Refer to 7x blinking

A: Check wiring

B: Check basic setting of control board (DIPs)

A: Remove object

B: Check wiring. Check resistor 8.2KOhms

C: Check basic setting of control board (DIPs)

A: Check electric contact

B: Check by electrician

C: Allow battery to charge 24 hours

Replace contol board

Close (re-connect) release lever

Replace logic board

Check wiring

Reprogram the travel distance from gate fully closed

Summary of Contents for ART300 series

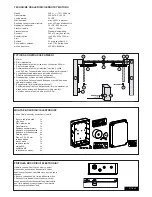

Page 23: ...ART 1 ART 2 ART 3 ART 6 ART 7 115 o 90 o 90 o 90 o 115 o 115 o 115 o 90 o 1 A B 2 3 A...

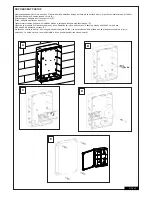

Page 25: ...6 7 8 9 A B 10 11 A B C D...

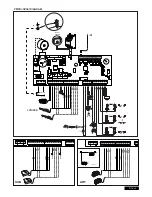

Page 26: ...ART 6 ART 7 41ABSC 5 41ASWG 454 41AART 63 ART 3AL 41AART 1022SA 41AART 1026SA 13 12...

Page 27: ......

Page 28: ...709446D 2010...

Page 234: ......

Page 235: ......