4

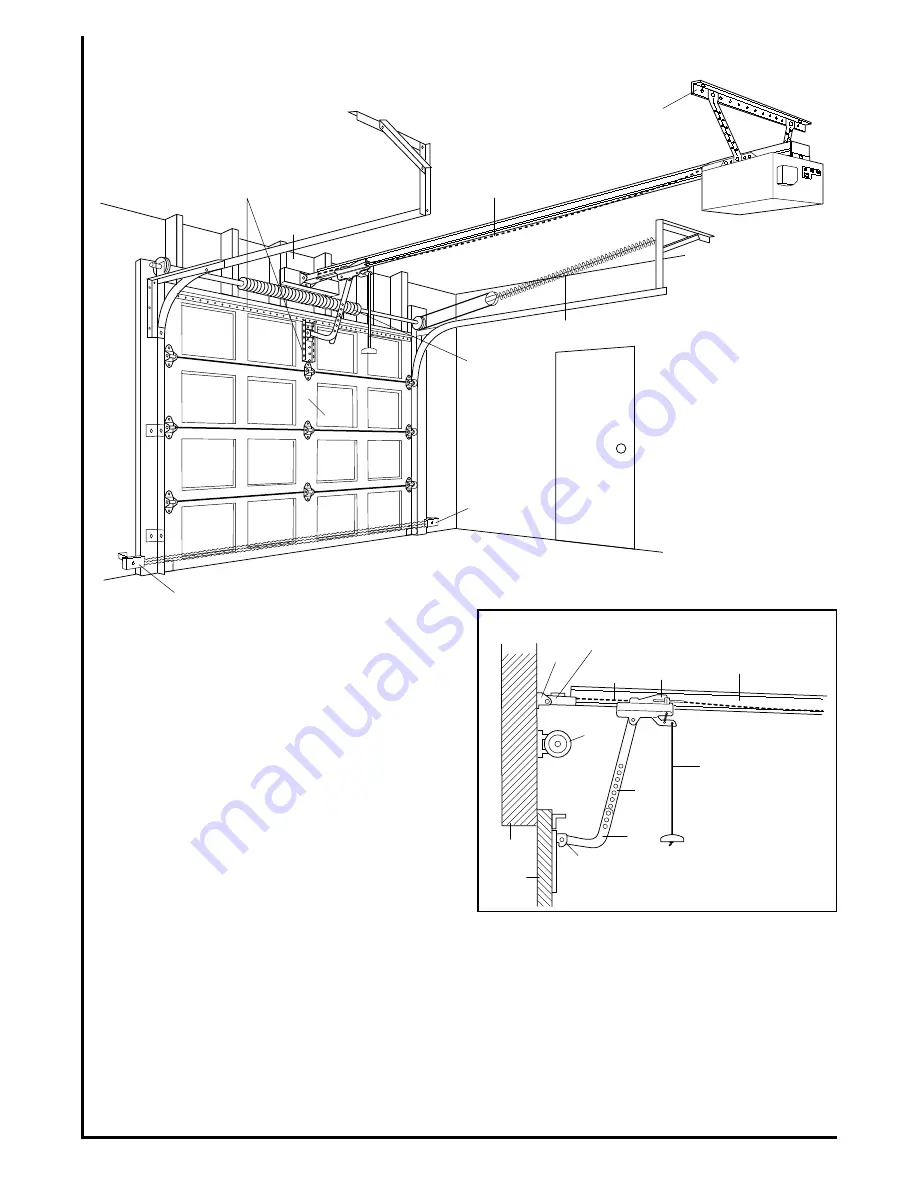

Safety Reversing Sensor

Horizontal and vertical reinforcement

is needed for lightweight garage doors

(fiberglass, steel, aluminum, door with glass panels, etc.).

See page 19 for details.

Support bracket &

fastening hardware

is required.

See page 12.

— — — — — — — —

Door Center

Header Wall

Safety

Reversing

Sensor

Floor must be level

across width of door

FINISHED CEILING

Extension Spring

Torsion Spring

Access Door

OR

Slack in chain tension

is normal when

garage door is closed.

Based on your particular requirements, there are

several installation steps which might call for

materials and/or hardware not included in the

carton.

• Step 1, page 8 - Look at the wall or ceiling above

the garage door. The header bracket

must be

securely fastened to structural supports.

• Step 5, page 12 - Do you have a finished ceiling in

your garage? If so, a support bracket and

additional fastening hardware may be required.

• Safety reversing sensor, page 16 - Depending

upon garage construction, wood blocks may need

to be fastened to mounting locations before

sensors are installed.

• Step 10, page 17 - Alternate floor mounting of the

safety reversing sensor will require hardware not

provided.

• Step 11, page 19 - Do you have a steel, aluminum,

fiberglass or glass panel door? If so, horizontal

and vertical reinforcement is required.

• Look at the garage door where it meets the floor. It

must close on the floor all the way across. Other-

wise, the safety reverse system may not work

properly. See page 23. Floor or door should be

repaired.

• If your door is more than 7 feet high, see longer

rails available on page 30.

Chain Pulley

Bracket

Header

Bracket

Trolley

Straight

Door

Arm

Manual

Release

Rope & Handle

Door Bracket

Garage

Door

Curved

Door

Arm

Garage

Door

Spring

Header

Wall

Chain

Closed Position

Rail

• The opener can be installed within 2 feet to the left or

right of the door center if there is a torsion spring or

center bearing plate in the way of the header bracket

or door bracket area. If your door has extension

springs, the opener

must be installed in the center of

the door. See pages 8 and 19.

Do you have an access door in addition to the garage

door? If not, Model 1702 Outside Quick Release is

required. See page 30.

You may find it helpful to refer back to this page as

you proceed with the installation of your opener.

Before you begin, survey your garage area. Do any of the following conditions apply to you?