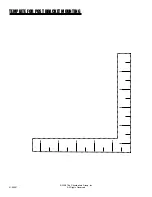

FAULT CODE

PROBLEM

CLEARED

1 Blink

Safety Sensors Disconnected. A loud beep will

be heard when a run command is given.

Check all low voltage wiring from sensors for breakage or poor

connections.

2 Blinks

Safety sensors connected wrong

Check for proper connections of (Red / +) and (Black / -) wires at

the control board. Polarity must to be maintained.

3 Blinks

Single button input "SWITCH" is shorted.

Check for shorted wires or stuck button on switch accessory.

4 Blinks

Safety Sensors are misaligned or blocked. A

loud beep will be heard when a run command

is given.

Check sensors path for obstruction or misalignment. When

sensors are properly aligned both indicator LED's on the sensors

will be lit.

7 Blinks

Control board issue.

Replace control board.

9 Blinks

Gate operator position sensor error

Check gate operator cable connections at the control board.

10 Blinks

Control board issue.

Replace control board.

11 Blinks

Force reversal while closing. Maximum safe

gate force was exceeded.

Check gate path for obstruction. Verify operator cable connections

at the control board.

12 Blinks

Force reversal while closing. Normal gate force

was exceeded.

Check for obstructions or excessive gate resistance. Relearn gate

force (press PURPLE BUTTON 2 times then cycle gate).

13 Blinks

Force reversal while opening. Normal gate

force was exceeded.

Power on reset

15 Blinks

Control board issue.

Replace control board.

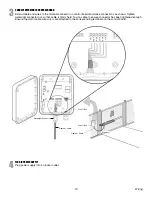

Troubleshooting

HAVING A PROBLEM?

Symptom: Operator will not run or respond to any

programming.

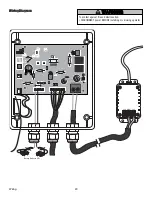

• Power supply not plugged into outlet or outlet without

power. Check circuit breaker.

• Issue with wiring from power supply to the gate

controller. Check connections at the power supply

terminals and the control board. To verify if power supply

is supplying appropriate power, check for 24Vac at the

terminals on the power supply marked

COM

and

24Vac

with a volt meter. Also, check for 24Vac at the end of the

two wires leading from the transformer to the control

board to verify wires are good.

Symptom: Operator will not respond to a remote

control.

• If the remote control battery is good, the

YELLOW

LED

on the control board will blink rapidly when the remote

control button is pressed. If not, replace battery.

• Remote control provided with operator is programmed

from the factory. If the LED blinks rapidly when pushing

on the remote control button and the operator does not

respond, try reprogramming the remote control.

Symptom: Relays on control board ‘click’ when remote

control command is given but the operator does not

move.

• Motor cable wiring from the operator to the control board

not connected correctly or loose. Check connections.

Symptom: Relays on control board ‘click’ when remote

control command is given but the operator does not

move.

• Motor cable wiring from the operator to the control board

not connected correctly or loose. Check connections.

Symptom: Gate stops and reverses.

• A fault has occurred. Check gate path for obstructions.

Check operation of gate manually to verify smooth

operation. Adjust force setting

(see

PROGRAMMING FORCE LEARN

).

Symptom: Gate opens but will not close.

• Safety Sensors are blocked or misaligned.

Symptom: Gate does not close automatically with TTC

enabled.

• Unit has lost power.

• Gate opened by a forced reversal.

• Safety sensors are blocked or misaligned.

• Party mode has been enabled.

Symptom: Alarm is sounding continuously.

• This indicates that the gate has had two consecutive

Gate Force obstructions and the control system requires

to be reset for continued operation. Check to ensure the

gate path is clear. To clear the alarm condition and

restore normal operation, push and release the

RESET BUTTON

on the outside of the control box.

Operation and Maintenance

28