1

INTRODUCTION

The following procedure replaces the LA500 arm trolley nut,

should it become damaged by a car strike to the gate or other

similar event. This procedure is intended to be performed in a

clean shop by personnel confident in performing such

procedures.

Most of the LA500’s internal drive train parts are factory

assembled under tight tolerances. Should any of these parts lose

alignment, reliable performance will be impacted. This

procedure’s performance may impact the arm warranty coverage;

therefore, if the subject arm is still covered under product

warranty, please consider replacing the arm instead of performing

this procedure. Retain all hardware; it will be needed for

reassembly.

To reduce the risk of INJURY or DEATH:

• DISCONNECT power and battery BEFORE installing or

servicing operator.

• See manual regarding maintenance and required safety

testing prior to servicing.

TROLLEY NUT SERVICE KIT

MODEL K75-39337

TOOLS NEEDED

•

LA500 control box with photoelectric sensors

• Torque

screwdrivers

• Metric

Allen

wrench

• 12V,

7A

battery

•

Flathead and Phillips head screwdrivers

•

Fastener (E-ring) pliers

• Needle

nose

pliers

CARTON INVENTORY

Description

QTY

Trolley nut

1

ADDITIONAL PARTS INCLUDED

The following items are provided for additional damage that

occurred when the trolley nut was broken, or for parts that may

have become lost in the performance of this procedure.

Description

QTY

Pan Head Screw, M5

2

Split Washer, M6

3

Pan Head Screw, M6

1

Nut, M6

3

O-ring

1

Pin

1

Retaining Ring

1

Retaining Ring

1

Bearing

1

Trolley Plate

2

Bushing Retainer

1

Flat Washer, M6

2

Screw M6

2

Trolley Pin

1

Base plate

1

Arm Gasket

1

Screw, M5

12

WARNING:

This product can expose you to chemicals

including lead, which are known to the State of California to

cause cancer or birth defects or other reproductive harm.

For more information go to

www.P65Warnings.ca.gov.

INSTALLATION

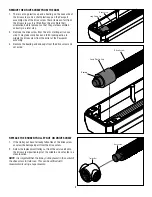

OPEN THE ARM

1. Invert the arm to gain access to the top cover screws.

2. Remove the 12 top cover screws using a T25 torque

screwdriver or wrench.

3. Turn the arm back to normal operating orientation.

4. Carefully separate the top cover from the rest of the arm.

Note that the post bracket might fall out.

5. Place the top cover in a safe, clean location. Make sure that

the arm gasket does not get contaminated.

Post Bracket

Top Cover

Top Cover Screws