12

TEST

NOTE:

Refer to the Model LA500 operator manual for

programming or installation instructions.

Bench test the arm.

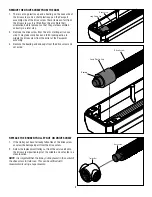

1. Connect the arm into an LA500 control box for testing.

a. Wire the cables from the arm to the arm one connector of

the LED circuit card in the LA500, following the wire colors

listed on the board and shown on the connector.

b. If the model of the ebox requires entrapment protection,

connect a set of photoelectric sensors to the board to the

close eyes input, and align the photoelectric sensors on the

bench top.

c. Place timer to close in the OFF position (fully

counterclockwise).

d. Place the reversal force setting to 1 o’clock.

e. Disconnect the expansion board.

2. Learn

arm

limits.

a. Clear previous limits from the board by pressing and

holding the set open and set close buttons simultaneously

until the operator beeps. Both the set open and set close

LEDs should be flashing.

b. Place the gate toggle switch into the arm1 position.

c. Using the move gate buttons, move the travel assembly to

the outer limit of the arm. Press set close.

d. Using the move gate buttons, move the travel assembly to

the inter limit of the arm. Press set open.

e. Make sure that both the set open and set close buttons are

extinguished.

f. If the arm fails to set limits, or presents an error code

during this operation, there is either a problem with the

assembly of the arm, or an additional failure within the

arm.

3. Perform a complete open and close cycle to the arm, making

sure that no unusual noise is heard, and that the trolley

smoothly moves from open to close limits and vice versa.

a. Press the close button.

• The travel assembly should move towards the outer

limit.

• The blue LEDs on the arm top should illuminate.

b. Press the open button.

• The travel assembly should move towards the inter

limit.

• The blue LEDs on the arm top should illuminate.

c. Listen to the trolley in motion to ensure that there are no

interference or nuisance noises from the arm while the

travel assembly is in motion.

d. The blue LEDs on the arm top should illuminate.

4. If the arm passes these steps, it is ready for field placement.