28

FINE TUNE THE FORCE

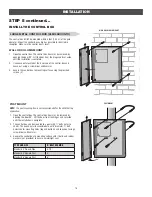

The REVERSAL FORCE DIAL on the control board is used for fine tuning

the force in cases where wind or environmental changes may affect the

gate travel.

Based on the length and weight of the gate it may be necessary to make

additional force adjustments. The force setting should be high enough

that the gate will not reverse by itself nor cause nuisance interruptions,

but low enough to prevent serious injury to a person. The force setting is

the same for both the open and close gate directions.

1. Open and close the gate with the test buttons.

2. If the gate stops or reverses before reaching the fully open or closed

position, increase the force by turning the force control slightly

clockwise.

3. Perform the “Obstruction Test” after every force setting adjustment

(see below).

OBSTRUCTION TEST

ADJUSTMENT

LIMIT AND FORCE ADJUSTMENT continued...

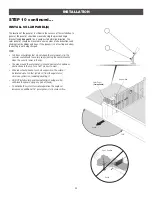

ADJUST THE LIMITS

After both limits are set and the operator is ready to run, one limit can be

adjusted independently from the other by following steps 1-3 of the Initial

Limit and Force Adjustment section, on page 27.

OPEN Limit

CLOSE Limit

3

2

1

60

180 MIN

MAX

ING

BATT LOW

ACC PWR OVLD

DIAG

C

SE

REVERSAL

FORCE

NETWORK

OPEN

CLOSE

ST

OP

TEST

BUTTONS

RSAL

RCE

XMITTER

NETWORK

2

1

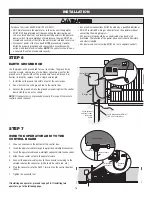

SET OPEN SET CLOSE

PRESS &

RELEASE

OPEN

CLOSE

ST

OP

TEST

BUTTONS

RSAL

RCE

XMITTER

NETWORK

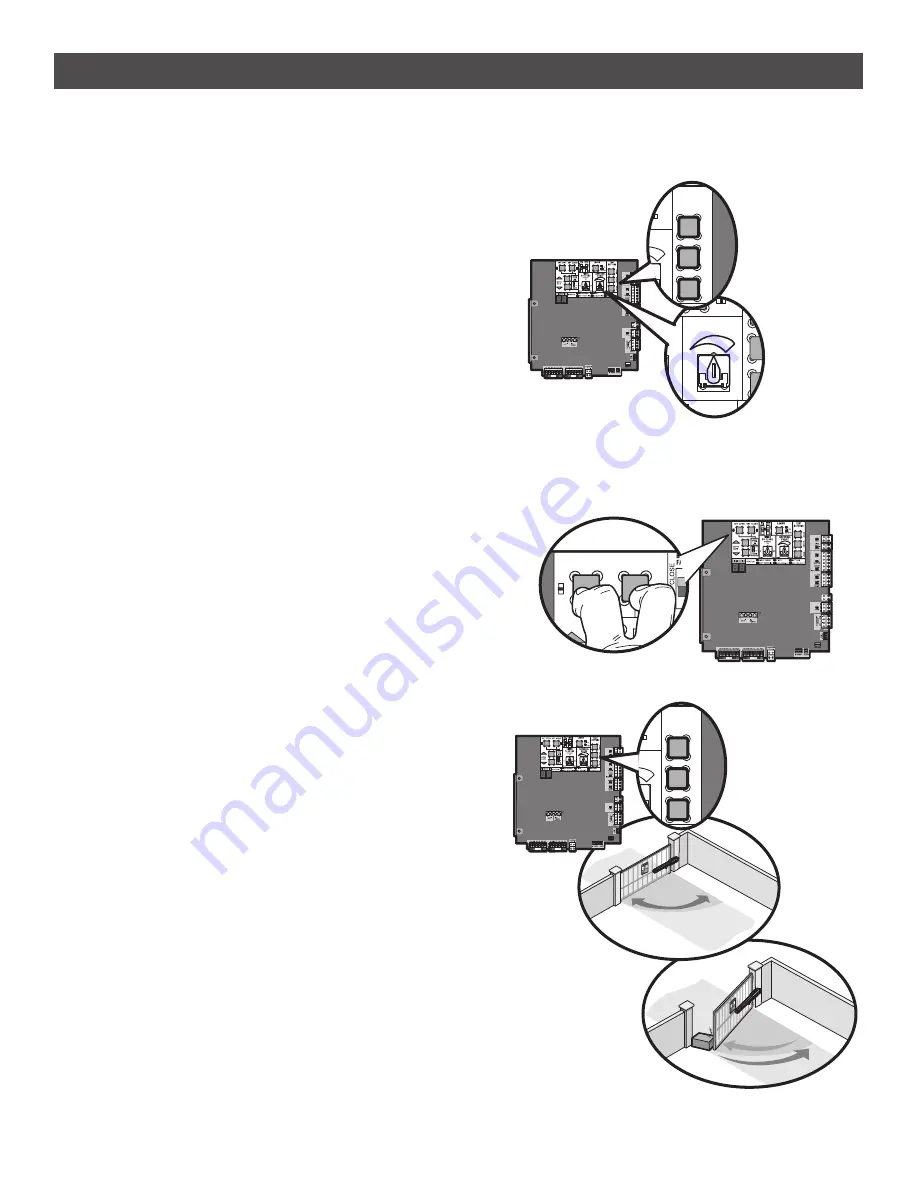

The operator is equipped with an automatic obstruction sensing feature.

If the gate encounters an obstruction during motion, the operator will

automatically reverse direction of the gate for a short time and then stop

the gate. After any adjustments are made, test the operator:

1. Open and close the gate with the test buttons, ensuring that the gate

is stopping at the proper open and close limit positions.

2. Place a solid object between the open gate and a rigid structure.

Ensure that the gate, the solid object, and the rigid structure can

withstand the forces generated during this obstruction test.

3. Run the gate in the close direction. The gate should stop and reverse

upon contact with the solid object. If the gate does not reverse off

the solid object, reduce the force setting by turning the force control

slightly counter-clockwise. The gate should have enough force to

reach both the open and close limits, but MUST reverse after contact

with a solid object.

4. Repeat the test for the open direction.