32

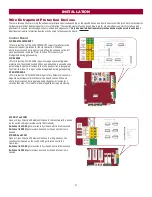

Maglock

LOCK (2 Terminals, N.C. and COM)

Relay contact output, Normally - closed (N.C.) output for maglocks.

Relay activates prior to motor activation and during motor run. Relay is

off when motor is off.

Miscellaneous wiring

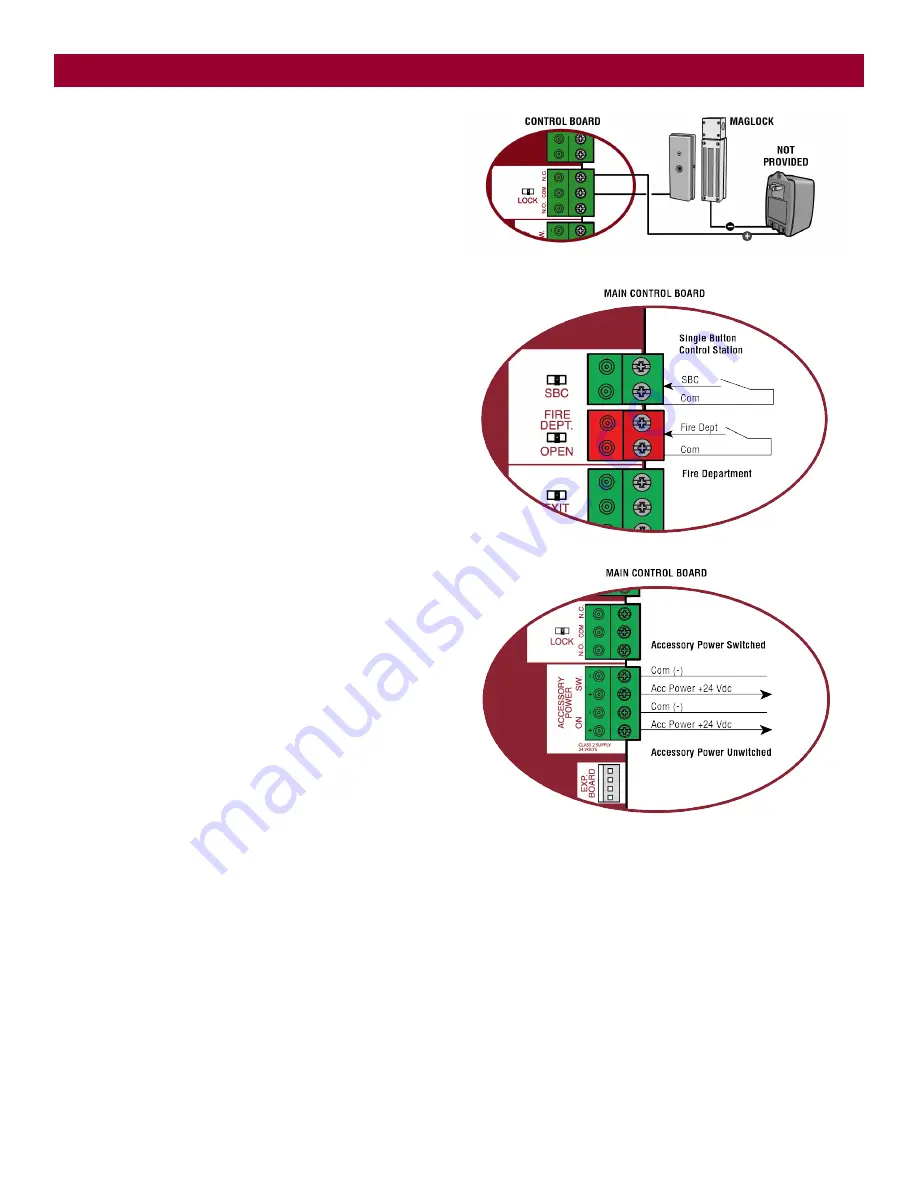

Single button control (SBC) (2 Terminals)

Gate command sequence - Open, Stop, Close, Stop,...

Soft open (maintained switch does not override external safeties and

does not reset alarm condition).

Fire department open input (2 Terminals)

Acts as hard open.

Maintained input overrides (ignores) external safeties (photoelectric

sensor and edge), pauses Timer-to-Close momentary input logic as

single button control and safeties remain active, re-enables Timer-to-

Close.

Accessory power 24 VDC, MAX 500 mA (4

Terminals)

l

SWITCHED: Switched ON with gate motion and at the open limit

when Timer-to-Close is active. Turns off 5 seconds after motion.

l

UNSWITCHED: 24 Vdc voltage out to power accessories, always ON.

ACCESSORY WIRING