14

INSTALLATION STEP 7

Install the Light

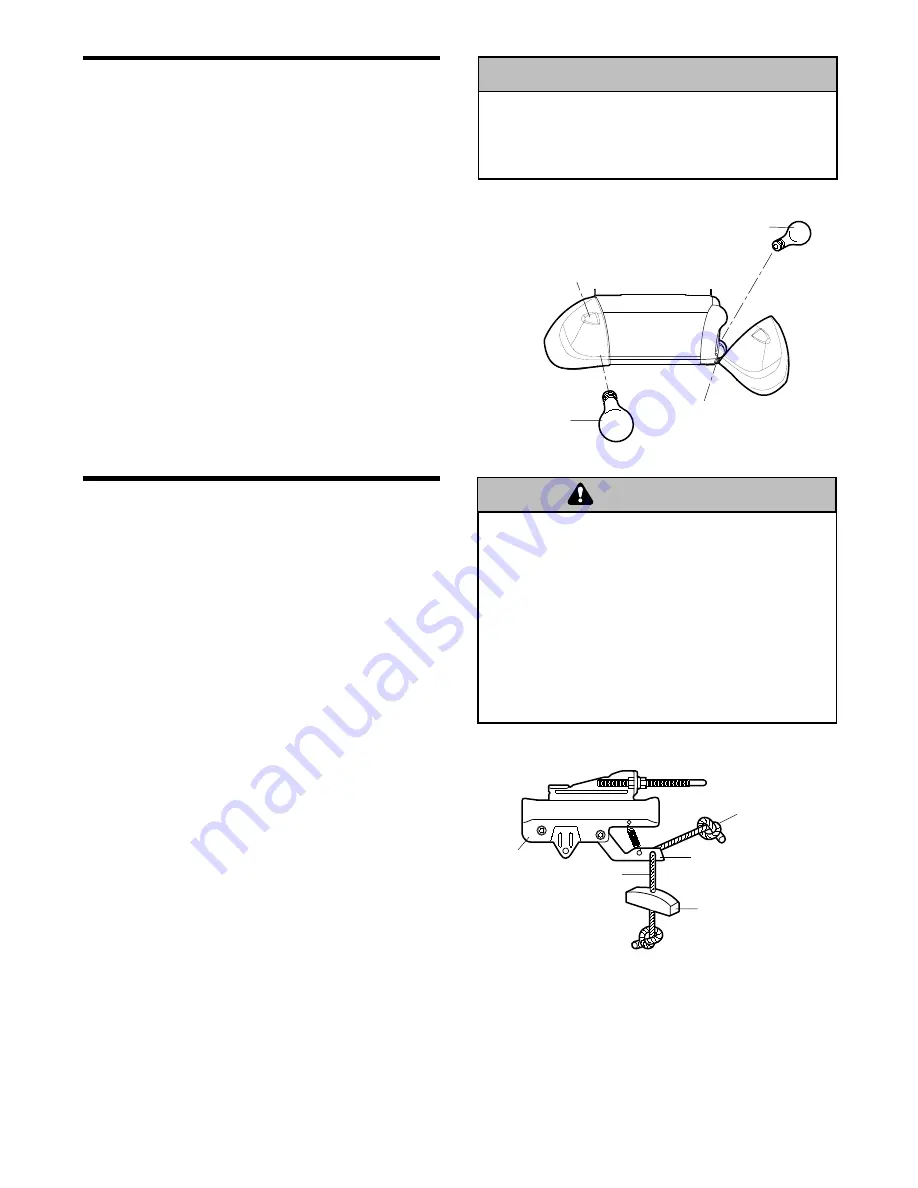

• Press the release tabs on both sides of lens.

Gently rotate lens back and downward until the

lens hinge is in the fully open position. Do not

remove the lens.

• Install up to a 100 watt maximum light bulb in each

socket. The light will turn O

N

and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the lights will turn OFF.

• Reverse the procedure to close the lens.

• If the bulbs burn out prematurely due to vibration,

replace with a Garage Door Opener bulb.

NOTE:

Use only standard light bulbs. The use of

short neck or speciality light bulbs may overheat the

endpanel or light socket.

INSTALLATION STEP 8

Attach the Emergency Release

Rope and Handle

• Thread one end of the rope through the hole in the

top of the red handle so “

N

OTICE” reads right side

up as shown. Secure with an overhand knot at

least 1" (2.5 cm) from the end of the rope to

prevent slipping.

• Thread the other end of the rope through the hole

in the release arm of the outer trolley.

• Adjust rope length so the handle is 6 feet (1.

8

3 m)

above the floor. Ensure that the rope and handle

clear the tops of all vehicles to avoid

entanglement. Secure with an overhand knot.

NOTE:

If it is necessary to cut the rope, heat seal

the cut end with a match or lighter to prevent

unraveling.

Trolley

NOTICE

Overhand

Knot

Emergency

Release Handle

Rope

Trolley

Release Arm

To prevent possible OVERHEATING of the endpanel or

light socket,

• DO NOT use short neck or specialty light bulbs.

• DO NOT use halogen bulbs. Use ONLY incandescent.

WARNING

CAUTION

WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH from a

falling garage door:

• If possible, use emergency release handle to

disengage trolley ONLY when garage door is

CLOSED. Weak or broken springs or unbalanced

door could result in an open door falling rapidly

and/or unexpectedly.

• NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

• NEVER use handle to pull door open or closed. If

rope knot becomes untied, you could fall.

WARNING

CAUTION

WARNING

WARNING

Lens

Hinge

100

W

att (Max)

Standard Light Bulb

Release Tab

100

W

att (Max)

Standard Light Bulb