2

WIRING

TROUBLESHOOTING

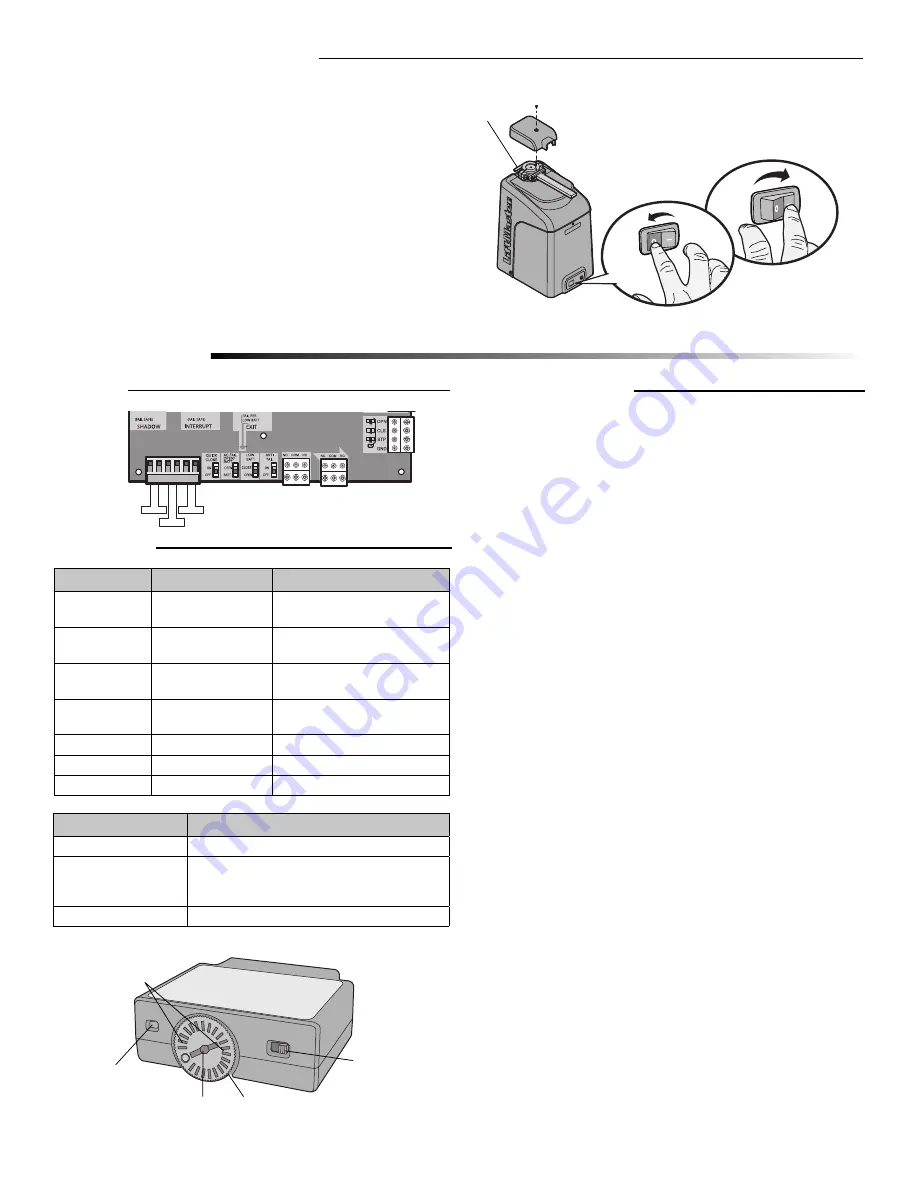

Blue LED

(located under dial)

Dial

Boost Switch

Frequency Button

OPERATION

White LEDs

(located under dial)

Exit Loop

Interrupt Loop

Shadow Loop

EXPANSION BOARD

LOOP DETECTOR

MANUAL DISCONNECT

Press the reset switch to RESET/DISCONNECT. Release the handle on the operator arm

to allow the gate to be opened and closed manually. On a dual gate application the

handle must be released on both operators. To resume normal function tighten the

handle by pushing it down.

RESET SWITCH

The reset switch is located on the front of the operator and serves several functions.

Toggling the reset switch will stop a moving gate during a normal open/close cycle,

like a stop button. The operator does not need to be reset after doing this. The reset

switch will disable the gate in the present position and will energize the solenoid lock

for two minutes and disable the maglock for two minutes.

Manual Disconnect

Handle

RESET/DISCONNECT

NORMAL OPERATION

MODELS CSW24V AND CSW24VH

1

Turn the dial to TEST. The loop detector will send a signal to the main board

simulating a vehicle over the loop.

Exit:

If the gate is closed, it will open or if the gate is already open it will

remain open.

Shadow:

Active ONLY when the gate is in the open position. If the gate is

open, it will remain open.

Interrupt:

If the gate is closing, it will open.

Turn the dial back to the desired sensitivity setting.

BLUE LED

WHITE LED

EXPLANATION

1 Blink (every 10

seconds)

OFF

Normal Operation

2 Blinks

Rapid Blinks (active fault)

or OFF

Open Loop (see TROUBLESHOOTING)

3 Blinks

Rapid Blinks (active fault)

or OFF

Shorted Loop (see TROUBLESHOOTING)

4 Blinks

Rapid Blinks (active fault)

Failed Authentication (see

TROUBLESHOOTING)

OFF

2 Blinks

Successful Reset

OFF

Slow Blinks

Loop detector is in TEST or PROG mode

Solid

Solid

Active Loop

DIAL SETTINGS

EXPLANATION

TEST Mode

Used to test the loop detector

1-8

Determines the sensitivity setting for the loop detector:

1 is the lowest sensitivity (large vehicle) setting and 8 is the

highest sensitivity (small vehicle). Default setting is 4.

PROG Mode

Used to change the frequency of the loop detector

2

Open or Shorted Loop (2 and 3 Blink errors):

Test the loop detector (refer to TEST THE LOOP DETECTOR section). If the loop

detector passes the test, this indicates the loop detector is working properly and there

is an issue with the loop wiring.

Failed Authentication (4 Blink error):

• Check the wire connecting the expansion board to the main board

or

• Unplug the loop detector then plug it back into the same slot (clears all faults and

keeps the current frequency settings, authenticates)

or

• Unplug the loop detector. Then unplug the J15 plug on the operator’s control

board and plug it back in after 2-3 seconds. This allows the loop detector to be

plugged into a different slot (clears all faults and keeps the current frequency

settings, authenticates).

To clear a fault:

• Press the reset button on the operator (clears all faults)

or

• Unplug the loop detector then plug it back into the same slot.

The loop is making false detections:

• There is crosstalk between the LOOPDETLM and the alternate loop detector

or

• Change the frequency or lower the sensitivity setting of the loop detector.

The loop will not activate when a vehicle passes over it:

• Turn the boost switch ON or increase the sensitivity of the loop detector

or

• If the blue and white LEDs are solid, indicating an Active Loop, and the operator

does not activate, there could be a fault. Once the loop is inactive, check the LED

codes for a fault (refer to LED table above).

TEST THE LOOP DETECTOR