11

INPUT COMMANDS CONNECTIONS

(Use common and normally open contacts from devices

connected to these inputs)

JP2 Input

This input will stop the gate and activate the siren.

This input is for connection to wired contact edge sensors at

pinch points and photo beams that run along either side the gate

panel when in open position (if dead panel is present one beam

should run along it).

Input Commands - J5 Connector Block at top of Control Board

Control wire connections at low voltage terminal strip will be at

the top of the electronic control board. Make connections to the

appropriate points for the desired operation. Wires should be UL

approved 600 volt rated and at least 18 awg. All external control

devices must have normally open dry contacts.

DO NOT

CONNECT ANY DEVICE WHICH WOULD DELIVER ANY VOLTAGE

OF ANY KIND TO THESE TERMINALS.

Terminals 9, 10, 11, 12 are the commons (0 Vdc) used to activate

the following inputs.

Terminals 1, 2, 3 Open -

These inputs will trigger gate open

when pulsed or hold gate open with maintained contact. When

released gate will close if closing timer is on or if close input is

given.

Terminal 4, Auxiliary Open

- This is the wired line of sight,

intended manual reset input. Use this input to reset the unit

after a 2nd sequential obstruction is sensed and gate is locked

with siren running. This input normally functions as listed

below.

Acts same as 1, 2, 3 above with S2-6 off. With S2-6 ON this

will operate as a pulse-open, pulse-close.

NOTE:

Pulse to close will only work when gate is at full open

position.

SIREN will run for 5 minutes after

2nd sequential obstruction

,

then turns itself off, however operator will require a reset signal

to J5 #4 to re-activate gate. In addition, cycling the ac power

will also reset unit.

Terminal 5, Safety -

Safety edge(s) and safety loop input. This

function will make the gate reverse and go back to the open

position if it was closing. Input is for all NORMALLY OPEN

contact safety devices. This input is disabled when gate is in the

full closed position. Use with vehicle loops, photo beams and

sensors.

Terminal 6, Close -

ANTI-TAIL GATE close input. When using a

vehicle detector, you must use the presence contacts (N.O. and

C.) This input will QUICK close gate after input is applied and then

removed. It will stop the open cycle and reverse gate to close.

(Example: Car crosses over close loop before gate reaches full

open position – gate will reverse and close).

NOTE:

The close input also acts as a safety-stop in that if gate is

closing and a tail-gater is sensed at the close input, the gate WILL

STOP its closing motion and not continue to close until the close

input is removed or gate is re-opened.

Terminal 7, Back-Away (For Barrier Arm Gate Only) -

This input

is recommended for use with our Mega Arm barrier gates. For

your Mega Slide X, please use terminals 1, 2 or 3 for your free

exit loop input.

Terminal 8, Shadow Loop -

This input operates as a hold open

only when gate is a full open position.

Terminals 9, 10, 11, 12 Common -

These inputs used for

common (0 Vdc) to above listed functions.

NOTE:

J5 inputs 1-8 are tied to LED indicators to assist in trouble

shooting.

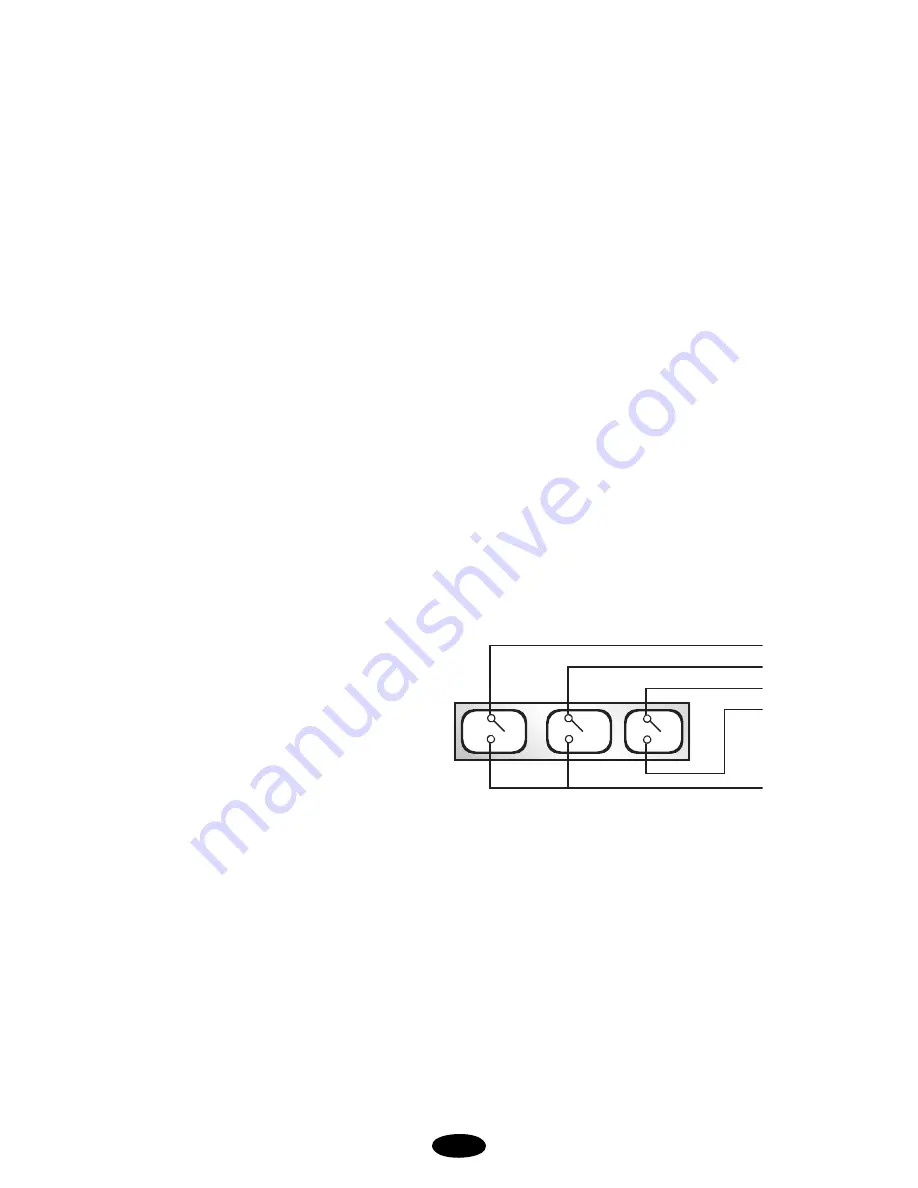

3-Button Control Station -

Not already in place. See diagram

below.

J5 Input #6

J5 Input #1

J5 Commons #9-12

Stop

Close

Open

JP2 Connector

(

NOTE:

Siren will sound

when stop button is

depressed)