14

RIGHT OR LEFT HAND OPERATION

UNIT SHIPS AS RIGHT-HAND

Method 1:

No longer used as of August 16, 2003. The S1-7

switch will be redefined.

Method 2:

Reverse the BLUE and ORANGE wire from the

motor and at J4 from the limit switches. With this method

DO NOT switch S1-7 to the ON position – leave in OFF position.

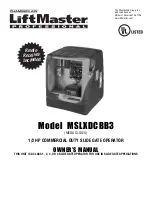

RIGHT HAND OPERATION

the motor (J4) and limit switch (J2)

wires will be

BLUE

then

ORANGE

NOTE:

Right hand operation is the default setting from the

factory.

LEFT HAND OPERATION

the motor (J4) and limit wires (at J2)

will be

ORANGE

then

BLUE.

As a

RIGHT HAND OPERATOR

the

LIMIT SWITCH

closest to the

gear box is the

CLOSE LIMIT.

As a

LEFT HAND OPERATOR

the

LIMIT SWITCH

closest to the

gear box is the

OPEN LIMIT.

LIMIT SWITCH ADJUSTMENTS

Disconnect power from operator. In order to adjust limit nuts, the

detent plate must be pushed down to allow free movement.

Spinning the nut closer to the switch will cause the gate to stop

sooner when approaching that switch. Spinning it away will delay

the nut in reaching that switch. With power disconnected,

(batteries and ac power) gate can be pushed open and closed to

assist in limit switch adjustments. After initial settings connect

power then run gate open and close to fine tune settings.

Remember to set the fast run timer (page 13) to allow gate to run

at the fast speed for as much of the gate travel as possible, but

still ensuring that it will slow down just before reaching the

closed position.

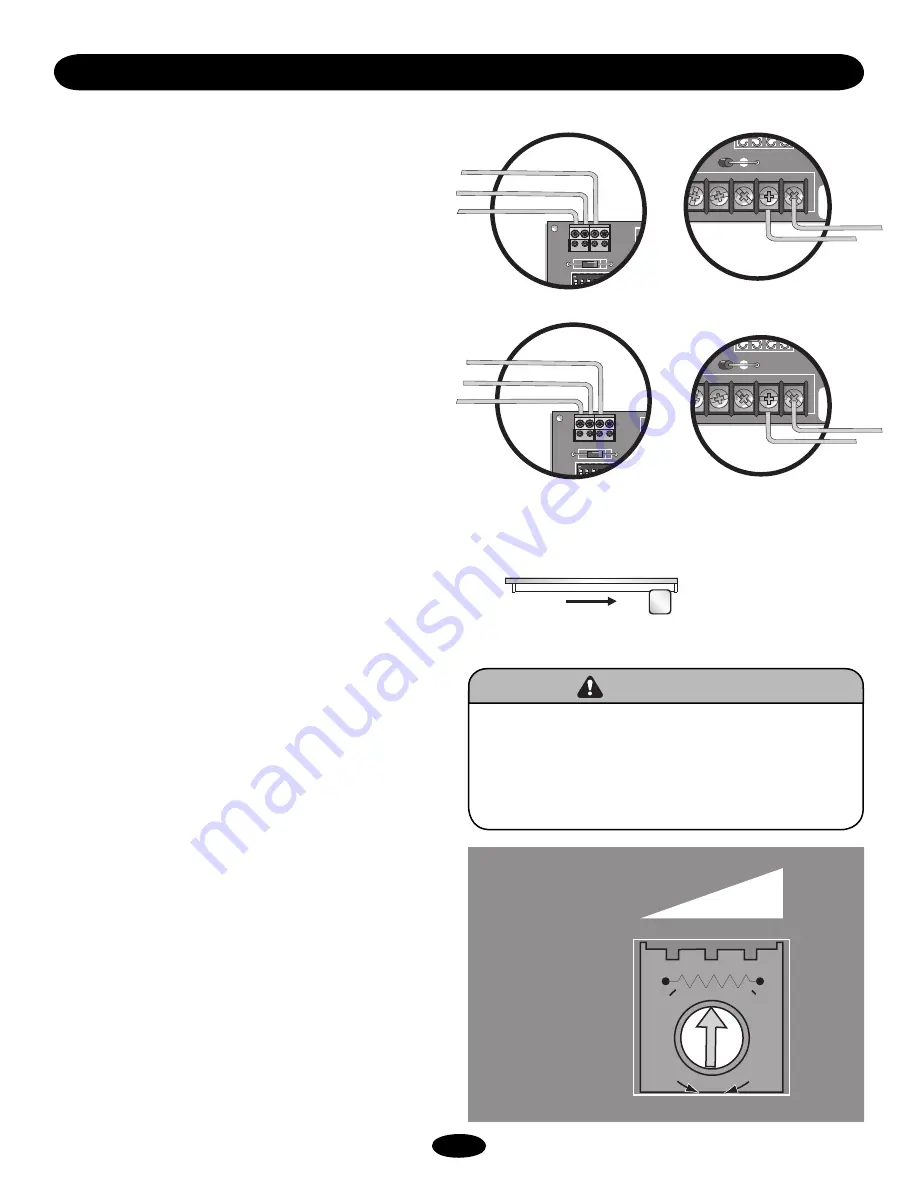

INSTANT REVERSE DEVICE (IRD)

The reverse device is an internal circuit that continuously

monitors the motor’s current for increased draw. This operator

has been shipped with the IRD1 set to a typical setting that will

likely move the gate from limit to limit. If necessary, the

sensitivity of this device can be adjusted by turning the IRD1 to

the right (CW, more sensitive) or left (CCW, less sensitive) in

small increments.

ADJUSTMENT

While running the gate open and closed, verify that the gate

travels as expected. Verify that the operator reverses off a rigid

obstruction located 1' from both the open and close limit. If the

operator does not reverse, adjust the IRD1 CW (more sensitive)

in small, 1 hour increments until the gate reverses off the 1'

obstruction. The gate should continue to travel from the open and

closed limits as expected.

If the gate did not complete the full open and closed travel, the

IRD1 setting should be incremented CCW (less sensitive) in

small, 1 hour increments until the gate travels the full distance.

Verify that the operator reverses off a rigid obstruction located 1'

from both the open and closed limit.

Seasonal ambient temperature changes may make IRD1

adjustments necessary. If during the setup, a double entrapment

condition occurs, refer to the troubleshooting section to rest the

gate.

A D J U S T M E N T S

To prevent possible SERIOUS INJURY or DEATH:

• After ANY adjustments, verify that the operator reverses off a

rigid obstruction located 1' from both the open and close

limits.

• Test instant reverse device (IRD) monthly.

• Adjustment MUST be made by qualified service personnel.

IRD1

C7

12

9

3

2

1

5

4

10

8

7

11

6

M

O

R

E

S

E

N

S

IT

IV

E

LE

S

S

S

E

N

S

IT

IV

E

ATTENTION

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

WARNING

WARNING

CAUTION

WARNING

WARNING

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

24VAC XFMR

F3

MOV

AT+

MOTOR

MOTOR

OF FUSE

24VAC XFMR

F3

MOV

BAT+

MOTOR

MOTOR

OF FUSE

AUX LIMITS

1

J2

S1

1

2

3

4

5

6

7

8

S2

1

D1Ø

AUX LIMITS

1

J2

S1

1

2

3

4

5

6

7

8

S2

1

D1Ø

RIGHT HAND OPERATION

LEFT HAND OPERATION

Blue

Green

OR

AUX. LIMITS

(Open & Close Limits)

AUX. LIMITS

(Open & Close Limits)

Orange

Blue

Green

Orange

Blue

Orange

Blue

Orange

RIGHT HAND OPERATION

Righthand operation is viewed

from the same side of the gate as

the operator with the operator to

your right.

Operator

NOTE:

Unit ships out as a right hand (default wiring setup).

Gate

Open