17

BATTERY CHECKOUT

When the batteries become weak the gate will begin to run

noticeably slower.

(

NOTE:

Batteries should only be checked when

you are sure they have had adequate time to fully charge.)

Turn

off the ac power and run gate for 5 to 10 cycles while observing

low battery indicator LED D12. If LED 12 comes ON, batteries are

too weak to function properly. If LED 12 does not light, then

voltage should be checked as they still maybe near failure.

Correct voltage is approximately 25.5 Vdc.

(

NOTE:

If LED D12

does light, gate will open to conserve batteries in this test or in a

real power loss, even if mode switch 8 on S2 is off.)

Return of ac

power will clear low battery indicator. Correct charge voltage is

27.5 Vdc with batteries not connected (Set with R63, shown on

the Control Board Layout page).

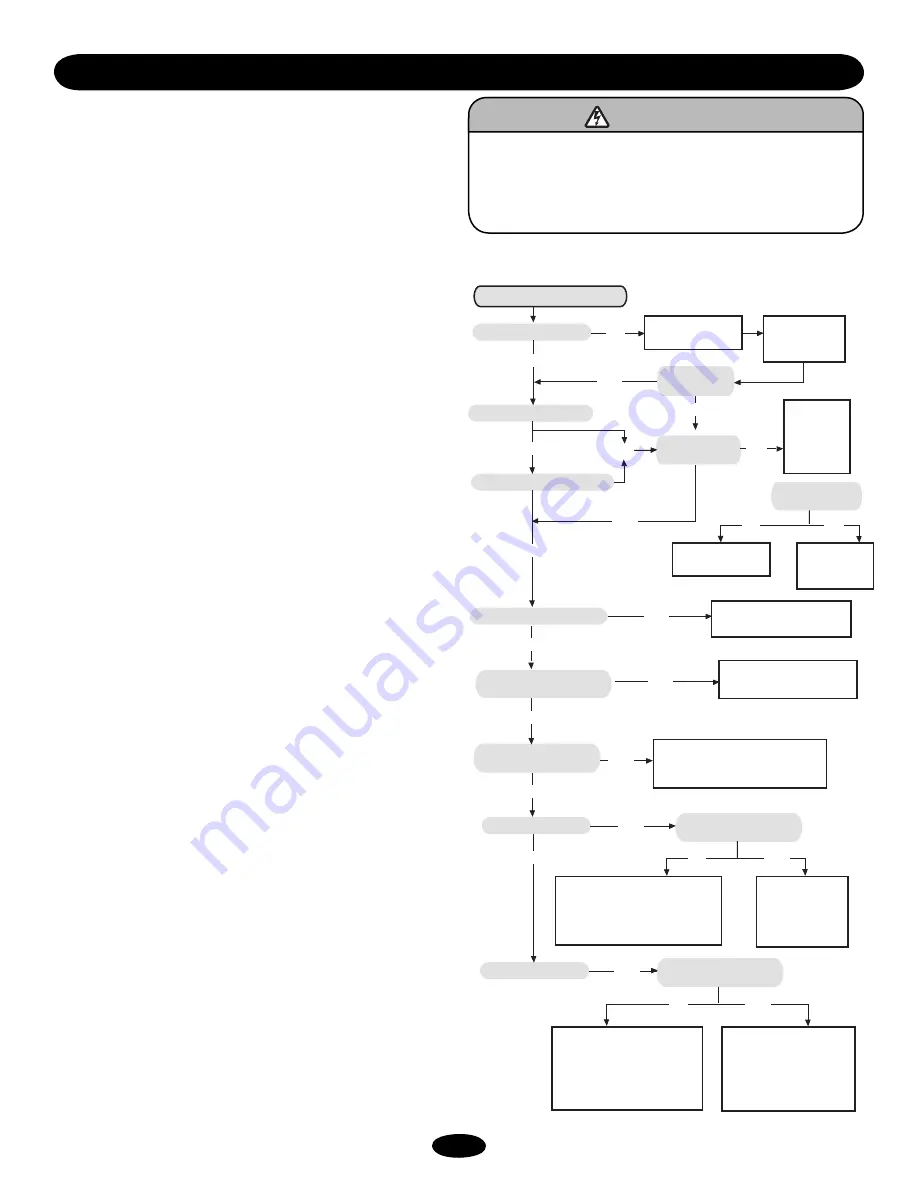

T R O U B L E S H O O T I N G

GATE NOT OPERATING

To prevent possible SERIOUS INJURY or DEATH from

electrocution or fire, BEFORE proceeding

• Disconnect ac power at the fuse box.

• Disconnect dc power at the battery connection.

ATTENTION

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

WARNING

CAUTION

WARNING

WARNING

WARNING

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

Gate will not operate.

Is the HBEAT flashing?

Check the battery

connections.

Check fuse F4.

Replace if blown.

No

Is the battery lo LED on?

Is the HBEAT

flashing now?

Yes

Is S2-8 (open on ac fail) on?

Yes

No

No

Is the ac power

LED on?

Yes

No

Restore ac

power and/or

turn ac

power switch

ON.

Is the ac power

LED on now?

Is the shadow input active?

No

Yes

No

Allow unit to

charge before

operation.

Check fuse F3, Replace

if blown.

No

Is the Safety, Backaway, or Open

input active?

No

Does the IRD light while

operating?

Remove the active input to allow

the gate to open.

Yes

Remove the active input to allow

the gate to close.

Is the IRD flashing?

Make sure the gate is not binding, then

adjust the IRD. Verify the gate reverses

when obstructed.

Yes

Yes

Is the IRD on solid?

Yes

Yes

No

Is the Entrapment

Alarm On?

Yes

No

The Edge input

(JP2) is active.

Clear obstruction

to restore

operation.

The run timer has expired. Inspect

the belt for slippage and verify the

fast run timer settings are correct.

Re-issue a command to start the

gate.

No

Yes

Is the Entrapment

Alarm On?

Yes

No

A double entrapment (E2)

condition has recently

occurred. Clear all

obstructions and use the

AUX input to reset the alarm

and gate.

A double entrapment (E2)

condition has occurred over 5

minutes ago. Clear all the

obstructions and use the AUX

input to reset the gate.