2

SAFETY INFORMATION

3

APPLICATION 4

OPERATOR SPECIFICATIONS

5-6

Weights and Dimensions . . . . . . . . . . . . . . . . . . . 5

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . 6

CARTON INVENTORY

6

PREPARATION 7

Preparing Your Door. . . . . . . . . . . . . . . . . . . . . . 7

Handing Identifi cation . . . . . . . . . . . . . . . . . . . . . 7

ASSEMBLY 7

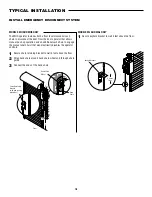

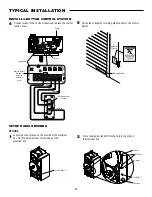

TYPICAL INSTALLATION

8-14

Determine Mounting Location for Operator . . . . . . . . . . 8

Install the Operator . . . . . . . . . . . . . . . . . . . . . 8-9

Install Emergency Disconnect System . . . . . . . . . . . . .10

Power and Ground Wiring Connections . . . . . . . . . . 11-12

Install 3-Button Control Station . . . . . . . . . . . . . . 12-13

Setup Radio Antenna . . . . . . . . . . . . . . . . . . . 13-14

ADJUSTMENT 15

Adjust the Limits. . . . . . . . . . . . . . . . . . . . . . . .15

Adjust the Clutch. . . . . . . . . . . . . . . . . . . . . . . .15

ENTRAPMENT PROTECTION

16-19

LiftMaster Monitored Entrapment Protection (LMEP) . . . . .16

Install the Photoelectric Sensors. . . . . . . . . . . . . . . .17

Mount the Photoelectric Sensors . . . . . . . . . . . . . . .18

Entrapment Protection Wiring Options . . . . . . . . . . 18-19

LOGIC BOARD LAYOUT

19

BASIC PROGRAMMING

20-23

Determine the Wiring Type . . . . . . . . . . . . . . . . 20-21

Remote Controls . . . . . . . . . . . . . . . . . . . . . . 21-22

Timer-to-Close (TTC) . . . . . . . . . . . . . . . . . . . 22-23

TESTING 23

EMERGENCY DISCONNECT

24

TROUBLESHOOTING 25-26

DIAGRAM 26

ACCESSORIES 27

CONTROL CONNECTION DIAGRAM

BACK COVER

TABLE OF CONTENTS