24

To avoid SERIOUS PERSONAL INJURY or DEATH disconnect

electric power BEFORE performing ANY adjustments.

ATTENTION

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

WARNING

WARNING

CAUTION

WARNING

WARNING

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

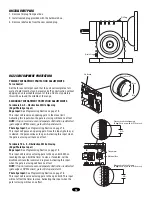

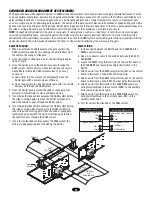

SOLENOID ACTUATED BRAKE

The brake minimizes over-travel caused by gate coasting. An

added feature of the brake is to assist in preventing back driving

of the gate. The brake is spring-applied whenever the motor is not

running. Anytime the motor is running, the electric solenoid

physically releases the brake.

A solenoid brake is standard on SL585/595 operators. The brake

is adjusted at the factory and should not need additional

adjustment for the the life of the friction pad.

Replace friction pads when necessary. Refer to the illustration for

identification of components for the solenoid type brake system.

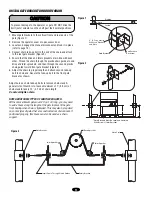

FRICTION CLUTCH

The friction clutch system is not an automatic reversing device. It

only serves to minimize damage to the gate operator and gate,

and to help minimize vehicle damage. If you need an external

automatic obstruction sensing device, items such as gate edges

and photo beams are available to help protect pedestrians

(page 4).

The clutch mechanism must be adjusted properly. During the

installation of the operator, you must tighten the clutch spring

lock nut so it is tight enough to operate the gate, yet loose

enough so that if the gate meets an obstruction, the clutch will

slip.

1. Loosen set screws of torque adjustment nut on the gear

reducer output shaft.

2. Back off torque nut until there is very little tension on the

Belleville washers.

3. Tighten torque nut gradually until there is just enough tension

to permit the operator to move the gate smoothly through a

complete open/close cycle, but to allow the clutch to slip if the

gate is obstructed.

4. Re-tighten the set screw that is directly over the flat portion of

the shaft.

CONTROL BOARD PROGRAMMING AND FEATURES

MOTOR LEARN FUNCTION (FORCE PROFILE)

This function is preprogrammed at factory. If either board or

motor is replaced, the control board will need to be

reprogrammed to “LEARN” the specific motor RPM profile of

your operator, the red button “S3” is provided for this. This is

important for accurate force control. Failure to do so may result

in improper and unsafe operation.

NOTE:

Motor Learn must be performed in stand alone mode.

1. Ensure that the operator remains attached to the gate

throughout the entire process.

2. Press the motor learn button. The yellow LED should start to

flash rapidly.

3. Push and hold down either the open or the close buttons. The

motor will run for a few seconds and then stop. If the LED

goes out the motor is learned. If the unit activates a limit

before completing the learn or some other error occurs the

LED will go back to on continuously. If this happens try

learning while running in the opposite direction.

Motor

Learn

Button (S3)

Brake Plate

Assembly

Release

Lever

Friction

Pads

Solenoid

Friction Clutch

Summary of Contents for LiftMaster Professional SL585

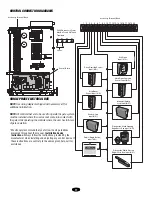

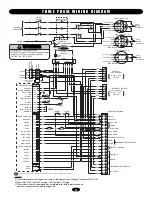

Page 32: ...32 T H R E E P H A S E S C H E M AT I C...

Page 39: ...39 N O T E S...