27

FAULT POSSIBLE

CAUSE

FIX

MASTER OR SECOND

OPERATOR IS NOT

FUNCTIONING PROPERLY

OPERATOR RUNS IN

WRONG DIRECTION

OPERATOR RUNS BUT

THEN STOPS AND

REVERSES DIRECTION

MOTOR RUNS BUT GATE

DOES NOT MOVE;

OPERATOR STOPS AND

ALARMS

OPERATOR OPENS

IMMEDIATELY UPON

POWER UP AND DOES NOT

CLOSE

OPERATOR HAS TROUBLE

LEARNING THE MOTOR

PROGRAMMING CHANGES

DO NOT EFFECT THE GATE

GATE EDGE PAUSES GATE

WHEN STRUCK DURING

OPENING

GATE DOES NOT ACTIVATE

TIMER TO CLOSE AFTER

THE CLOSE PHOTO EYE IS

BROKEN

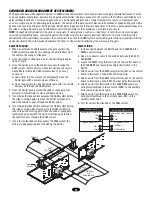

1) Failure to cycle power after setup

2) Communication wiring may be

damaged or improperly wired for dual

gate operation

3) Master or second unit is not

programmed correctly

T R O U B L E S H O O T I N G

➤

The power to each unit must be cycled in order to initiate proper

master/second communication if the operators were previously in

stand-alone mode.

➤

Make sure that the communication wire that is used is twisted pair

and not run in the same conduit with any power wiring. Failure to do

so will result in interference across the master/second

communication line.

➤

Review program settings page 20 and check both the master and

second for proper programming.

1) Operator’s main power is out of phase

(three phases only)

➤

Turn off the unit’s main power at the breaker and swap any two

power leads at the operator’s main power switch. Apply power and

retest the operator. See important note on page 12.

1) Entrapment (force pot) incorrectly set

2) Gate is binding or not running

smoothly

3) Clutch is not adjusted properly

4) Brake is not functioning properly

5) Observe red LEDs D29 and D31

6) RPM (Hall Effect) Sensor

is not aligned

➤

This pot must be set so that the gate will run smoothly normally and

reverse when encountering an obstruction.

➤

Disengage the manual release and roll gate open and close by hand at

normal operating speed. Make sure that the gate runs smoothly and

does not bind. If the gate is hard to move or binds, repair the gate.

➤

Adjust the clutch so that the operator can move the gate throughout

its travel without slipping but will slip when the gate hits an

obstruction.

➤

Make sure that the brake operates correctly. The brake should

disengage when the contactor activates and engage when the

contactor releases.

➤

Both LEDs will indicate the activation of entrapment protection

devices on terminals TB1-9 and TB1-10 on the control board.

Remove the devices and retest. If the operator now runs without fault,

check those accessories as well as their wiring.

➤

Make sure that the sensor is adjusted so that it is centered over the

limit shaft’s magnet and is 10-15 thousandths of and inch (business

card thickness) from the magnet.

➤

Replace the sensor if it is adjusted correctly but continues to fail.

1) Clutch is not adjusted properly

2) Operator’s manual release is not

aligned

➤

Adjust the clutch so that the operator can move the gate throughout

its travel without slipping but will slip when the gate hits an

obstruction.

➤

Make sure that the manual release is not engaged. The operator’s

manual release, when engaged, will set off the entrapment if the gate

is given a command to move.

1) Active or malfunctioning accessory

check the red input status LEDs,

D11-D13

➤

If any red LEDs are on, check the corresponding input. An installed

accessory may be wired incorrectly or malfunctioning. Remove the

accessory and test the operator.

➤

If the soft open or interrupt (safety) loop LED is on, make sure

factory plug-in loop detectors are working properly and appropriate

loops are installed on the loop input terminals.

1) Operator’s manual release is engaged

➤

Make sure the manual release is not engaged. The operator’s manual

release, when engaged, will not allow the entrapment sensor to

provide feedback to the control board when the operator is moving.

1) Check the save switch on switch S1-1

➤

If the switch S1-1 is in the on position, any subsequent programming

changes will not affect the gate. To make programming changes,

switch S1-1 off, make desired changes, and then switch S1-1 on.

1) Open obstruction input is

programmed incorrectly

➤

The open obstruction input has been programmed to function with

photo eyes, not gate edges. Refer to page 15 and reprogram the

obstruction inputs for correct operation.

1) Close obstruction input is

programmed incorrectly

➤

The close obstruction input has been programmed to function with

gate edges, not photo eyes. Refer to page 15 and reprogram the

obstruction inputs to match the accessories that are installed on

operator.

Summary of Contents for LiftMaster Professional SL585

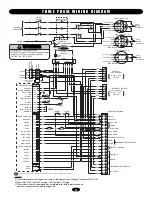

Page 32: ...32 T H R E E P H A S E S C H E M AT I C...

Page 39: ...39 N O T E S...