9-en

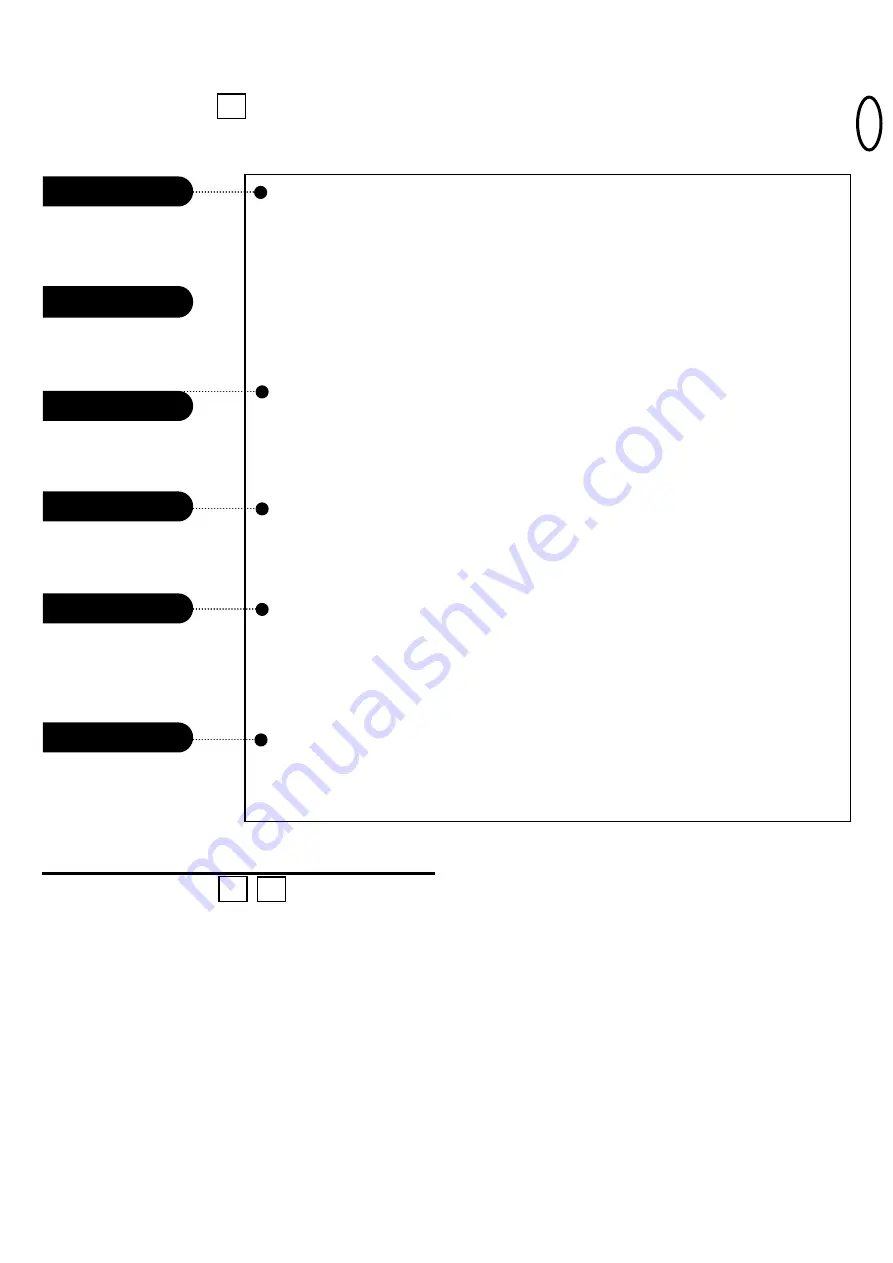

Your door operator is programmed with self-diagnostic capabilities. The “Learn” button/diagnostic LED will flash a number of times then pause

signifying it has found a potential issue. Consult Diagnostic Chart below.

Diagnostic Chart

Symptom: One or both of the Indicator lights on the safety reversing sensors do not glow steady.

• Inspect sensor wires for a short (staple in wire), correct wiring polarity (black/white wires reversed),

broken or disconnected wires, replace/attach as needed.

• Disconnect all wires from back of motor unit.

• Remove sensors from brackets and shorten sensor wires to 30-60mm from back each of sensor.

• Reattach sending eye to motor unit using shortened wires. If sending eye indicator light glows steadily,

attach the receiving eye.

• Align sensors, if the indicator lights glow replace the wires for the sensors. If the sensor indicator lights

do not light, replace the safety reversing sensors.

Symptom: LED is not lit on door control.

• Inspect door Control/wires for a short (staple in wire), replace as needed.

• Disconnect wires at door control, touch wires together. If motor unit activates, replace door control.

• If motor unit does not activate, disconnect door control wires from motor unit. Momentarily short across

red and white terminals with jumper wire. If motor unit activates, replace door control wires.

Symptom: Sending indicator light glows steadily, receiving indicator light is dim or flashing.

• Realign receiving eye sensor, clean lens and secure brackets.

• Verify door track is firmly secured to wall and does not move.

Symptom: The RPM Sensor = Short travel 150-200mm.

• Unplug unit to reset. Try to operate motor unit, check diagnostic code.

• If it is still flashing 5 times and motor unit moves 150-200mm (6-8"),The unit’s APE (Absolute Positioning

Encoder) may need to be replaced, for details contact your Chamberlain reseller.

Symptom: Door reverses while closing.

• Check for possible door obstructions and remove.

• Check that the cable tension monitor is properly connected to the operator.

• Replace the cable tension monitor.

Cable tension monitor

reversal.

Possible RPM sensor

failure. Unplug to reset.

Safety reversing sensors

slightly misaligned

(dim or flashing LED).

Door control or

wire shorted.

Safety reversing sensors

wire shorted or black/white

wire reversed.

Safety reversing sensors

wire open (broken or

disconnected).

1 FLASH

2 FLASHES

3 FLASHES

4 FLASHES

5 FLASHES

9 FLASHES

OR

3

6

Your door operator has already been programmed at the factory to operate with your hand-held remote control.

Below are instructions for programming your operator to operate with additional remote controls.

1. To enter the universal remote controls programming mode: Push and hold left and right button on the universal remote control simultaneously until

its LED goes constantly on for approx. 30 sec (= time frame for programming).

2. Press and release the orange “learn” button on the motor unit. The learn indicator LED will glow steadily for 30 seconds.

3. Within 30 seconds, select a button on the universal remote control, push it repeatedly until the programming LED respond.

4. Release the button when the motor unit LED blinks twice.

5. Push a different button on the universal remote control to exit (LED goes off) its programming mode.

To Add or Reprogram a Hand-held Remote Control

USING THE “LEARN” BUTTON

PROGRAMMING

3

8

3

7