WIRING OF CONTROL / SUMMARY

a) start with 230Volts supply cable.

Run cable through large cable bushing on the lefthand side.

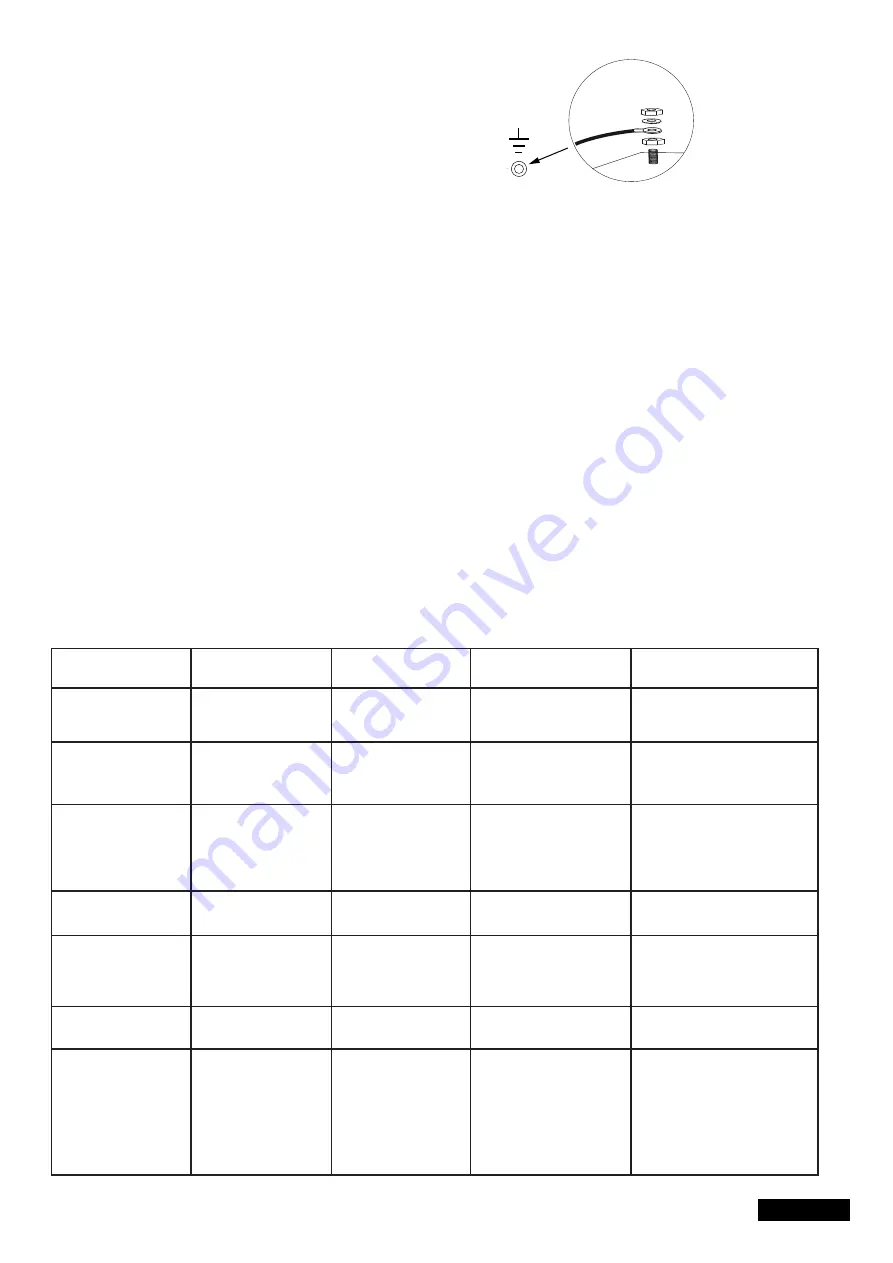

b) Attach cable eye to ground wire. Then connect ground wire to

base plate with washer and nut (exactly as shown in picture detail).

Connect all other cables to control.

CABLES AND WIRING

The usage of shielded cable in order to connect the motor to control board is highly recommended. Magnetic and inductive in

fl

uence of the signal in

the cables can produce electric noise and may disturb the function of the gate .

Generally avoid:

- Control board location far away from gate.

- 230Volt and low voltage in the same power line. Not allowed by electrical rules.

- Wiring of the infrared sensors, switches,

fl

ashing lamps & electric locks require a cable separately from the motor wiring.

- Other wirings like telephone intercoms, lights for garden etc. must be in separate cables.

- Rigid copper cables especially when thicker diameters are dif

fi

cult to manage during the installation and may result in bad connections with

functional issues. Use instead

fl

exible cables.

- Cable material not suitable for outside use. Use cables suitable for outside use and underground. Run the cables in conduits if the cable is not

suitable for placing in the ground (armoured or suitably protected). You may also consult your local electrician.

We recommend the following accessories:

- LA400-JB40E Kit for cable extension of one installation unit. Consists of 12m of cable 6-pole with identical colours, distribution box IP65,cable

screw joints and fastening material.

- 041ASWG-0482-50 Cable 50m for professional use. Consists of 50m of cable 6-pole with identical colours. Cut only as much as you need for the

current installation.

General wiring sizes:

The numbers mentioned in the table below are minimum requirements. It is always possible to use larger diameters.

- 230Volt Supply Power to controller: min. 0,75mm² 3-pole

- 230Volt Supply transformer installed separately (i.e. in the garage) and low voltage to gate. See table.

- Motor wiring: 2 wires min. 1,0mm², 4 wires min. 0,75mm² (or shielded cable)

- Electric locks: See table

- Switches, infrared sensors,

fl

ashing lamp: See table etc. min.0,5mm²

4/16 en

Operator Model

LYN, SCS, ART

motor wiring

SUB (underground)

motor wiring

Transformer separately

installed (in garage) and

low voltage supplied to

control board box.

Electric lock (12Volt)

wiring

External antenna

(Remove original

antenna of logic board)

Switches, Flashing lamp

etc.

Infrared Sensors

Distance

0m - 6m

2 x 1,0mm²

4 x 0,75mm²

2 x 1,0mm²

3 x 0,75mm²

0,75mm²

0,75mm²

Coax cable (Satellite

cable)

50 Ohm

0,5mm²

0,5mm²

Distance

6m - 10m

2 x 1,0mm²

4 x 0,75mm²

2 x 1,0mm²

3 x 0,75mm²

0,75mm²

0,75mm²

Coax cable (Satellite

cable)

50 Ohm

0,5mm²

0,5mm²

Distance

10m - 12m

Normal

Wiring

Use shielded cable for

the 3 smaller motor wires

1,0mm²

1,0mm²

Coax cable (Satellite

cable)

50 Ohm

0,75mm²

0,75mm²

Distance

12m – xx

Max. 15m

Use shielded cable for the 4

smaller motor wires.

Use shielded cable for the 3

smallermotor wires

Max. 30m; Min. 1,5mm²

Gate weight maximum 50% of

maximum motor power rating.

Max. 30m; Min. 1,5mm²

Coax cable (Satellite cable)

50 Ohm

(max. 25m)

Min. 0,75mm²

Max. 30m

Min. 0,75mm²

Max. 20m