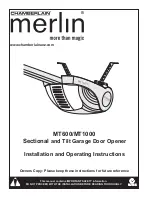

POSITION THE HEADER BRACKET

NOTE: The header bracket must be rigidly fastened

to a structural support of the garage. Reinforce the

wall or ceiling with a 40mm (1-1/2") board if

necessary. Failure to comply may result in improper

operation of safety reverse system

You can attach the header bracket either to the header

wall (1) or to the ceiling (3). Follow the instructions which

will work best for your particular requirements. With the

door closed, mark the vertical centreline (2) of the

garage door. Extend line onto header wall above the

door.

Open door to highest point of travel. Draw an

intersecting horizontal line (4) on header wall 50mm to

200mm above high point to provide travel clearance for

top edge of door (height varies depending on door type

see section 15).

3

1

2

4

12

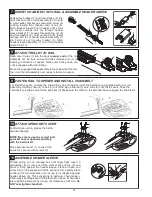

INSTALL THE HEADER BRACKET

NOTE: Refer to vertical centre and horizontal lines

created in section 12 for proper placement of header

bracket.

A. Wall Mount: centre the header bracket (1) on the

vertical centre line (2) with the bottom edge of the

header bracket on the horizontal line (4) (with the

arrow pointing toward the ceiling). Mark all of the

header bracket holes (5). Drill 4.5mm (3/16") pilot

holes and fasten the header bracket with wood screws

(3).

B. Ceiling Mount: Extend vertical centre line (2) onto the

ceiling. Centre the header bracket (1) on the vertical

mark no more than 150mm (6") from the wall. Make

sure the arrow is pointing toward the opener. Mark all

of the header bracket holes (5). Drill 4.5mm (3/16")

pilot holes and fasten the header bracket with wood

screws (3). For concrete ceiling mount, use concrete

anchors provided.

2

50mm

3

1

4

B

A

150mm

(6")

1 2

3

5

5

2

3

1

4

200mm

(50 to 200mm depending on door type)

13

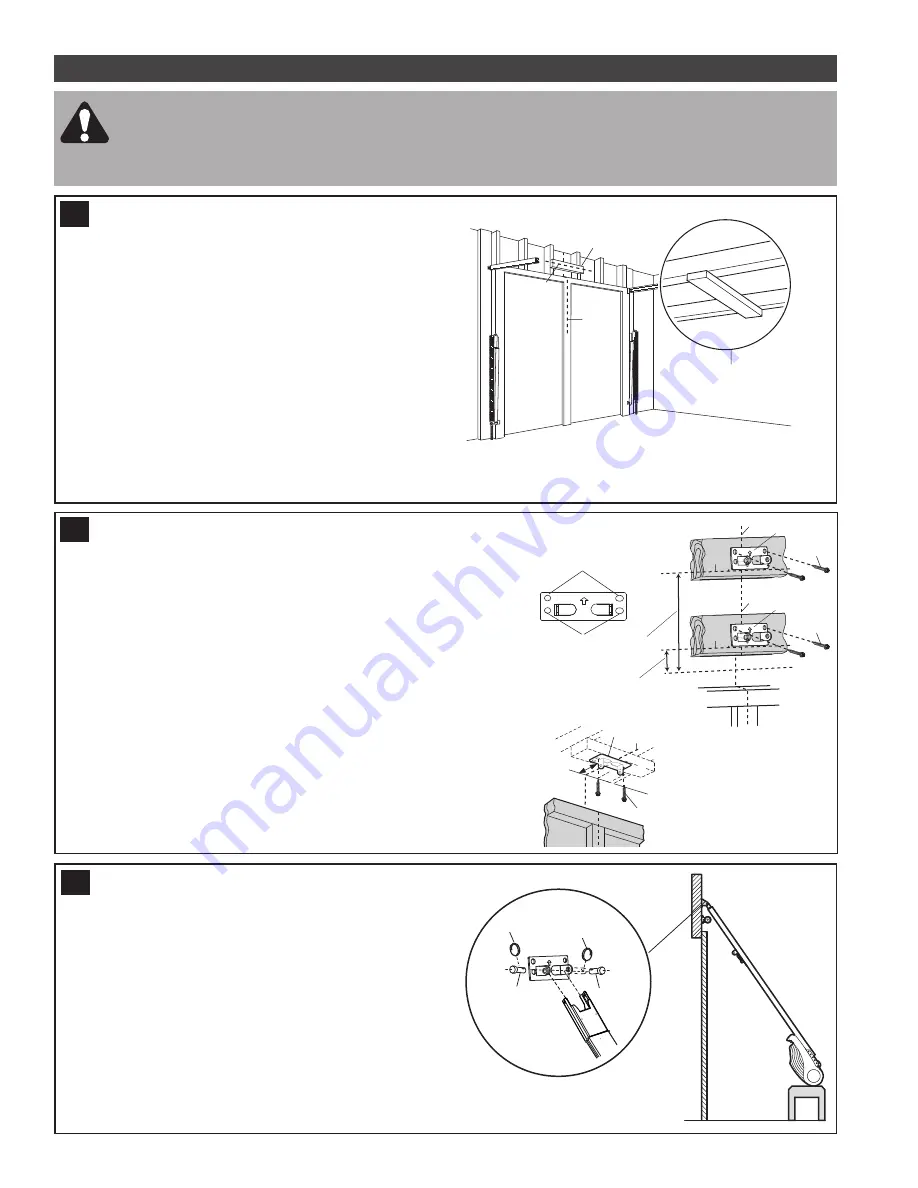

ATTACH RAIL TO HEADER BRACKET

Position opener on garage floor below the header bracket.

Use packing material to protect the cover. Raise rail until

holes in the header sleeve and holes in the header bracket

align. Join with clevis pin (1). Insert ring fastener (2) to

secure.

NOTE: To enable the rail to clear sectional door

springs, it may be necessary to lift opener onto a

temporary support. The opener must either be secured

to a support or held firmly in place by another person.

2

1

1

2

14

Wear protective goggles when working overhead to protect your eyes from injury.

Disengage all existing garage door locks to avoid damage to the garage door.

To avoid serious personal injury from entanglement, remove all ropes connected to the garage door

before installing the opener.

It is recommended that the opener be installed 2.1m (7 feet) or more above the floor where space permits.

INSTALLATION SECTION

5