2

3

4

NOTIC

E

2

1

17

2

1

24V/21W Max.

18

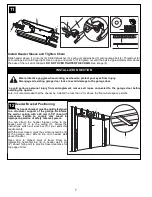

Attach Emergency Release Rope & Handle

Thread one end of rope (1) through hole in top of red handle

so "NOTICE" reads right side up as shown (3). Secure with

an overhand knot (2). Knot should be at least 25mm (1")

from end of the rope to prevent slipping.

Thread other end of rope through hole in release arm of the

outer trolley (4). Adjust rope length so that handle is 1.8m

(6 feet) above the floor. Secure with an overhand knot.

NOTE:

If it is necessary to cut rope, heat seal cut end with

a match or lighter to prevent fraying.

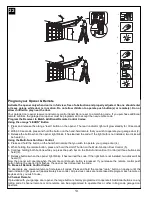

Connect Electric Power

TO AVOID INSTALLATION DIFFICULTIES, DO NOT RUN THE GARAGE DOOR OPENER UNTIL

INSTRUCTED TO DO SO.

Ensure door opener is installed to a power outlet with trip switch or fuse.

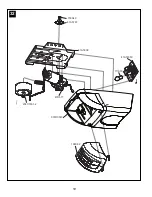

Replacing the light

Gently pull lens (2) downward until the lens hinge is in the fully

open position. Do not remove the lens. Install a 24V/21W

maximum light bulb (1) in the socket as shown. The light will

turn on and remain lit for 2-1/2 minutes when power is

connected. After 2-1/2 minutes it will turn off. To close, gently

push diffuser up until engaged.

Replace burnt out bulbs with heavy duty light bulbs.

19

1

2

A. 0-100mm

B. 150-250mm

3

4

7

6

2

1

4

5

3

A

4

B

7

6

A

B

1

4

C

1

2

3

3

1

2

4

10

1

2

1

2

1

2

3

3

1

2

4

4

1

4

3

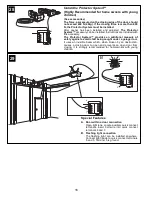

Fasten Door Bracket

If you have a canopy garage door, a door arm conversion kit is required. Follow the installation instructions included with the

replacement door arm. Exercise care in removing and assembling arm conversion kit. Keep fingers away from the sliding

parts.

NOTE:

Horizontal and vertical reinforcement is needed for lightweight garage doors.

Sectional and One-Piece Door Installation Procedure:

Door bracket (1) has left and right side fastening holes. If your installation requires top and bottom fastening holes use

both the door bracket and door bracket plate (2) as shown.

1. Center door bracket (with or without door bracket plate, as required) at the top inside face of door as shown. Mark

holes.

A.Standard Sectional or One-piece doors: locate bracket at inside face of the door.

B. Sectional doors with two horizontal roller channels: 150 - 250mm below the top of the door.

2. A. Wooden doors

Drill 8mm holes (5/16") and fasten the door bracket with nut, lock washer, and carriage bolt (3).

B. Sheet metal doors

Fasten with wood screws (4).

C. One-piece door optional

Fasten with wood screws (4).