2

MOTOR

TYPE:

.................................Intermittent Duty

HORSEPOWER:

................

MGJ:

1/2Hp 1 or 3 Phase

LGJ

: 1/4 Hp 1 Phase

SPEED:

...............................

MGJ:

1050 RPM

LGJ:

1725 RPM

VOLTAGE:

..........................

MGJ:

115, 60HZ, 1Ph

230V, 50 or 60Hz, 3Ph

230V, 60Hz, 1Ph

380V, 50Hz, 3Ph

460V, 60Hz, 3Ph

LGJ:

115V, 60Hz, 1Ph

CURRENT:

See motor nameplate

MECHANICAL

DRIVE REDUCTION:

.... . . . . . . . . . . . 40:1 Reduction

(Heavy duty wormgear-in-oil-bath speed reducer)

OUTPUT SPROCKET:.

..........Size #41

DOOR SPEED:

. . . . . . . . . .

MGJ:

1Ph, 23RPM

3Ph, 39RPM

LGJ:

.1Ph, 43RPM

BEARINGS:

.................Heavy duty wormgear-in-oil-bath

speed reducer.

SAFETY

DISCONNECT :

.......................Floor level disconnect for

emergency manual door operation.

REVERSING EDGE:

...............(Optional) Electric or

pneumatic sensing device attached to the bottom edge

of door

A REVERSING EDGE IS STRONGLY RECOMMENDED

FOR

ALL

COMMERCIAL OPERATOR INSTALLATIONS.

REQUIRED

WHEN THE 3 BUTTON CONTROL STATION

IS OUT OF SIGHT OF DOOR OR ANY OTHER

CONTROL (AUTOMATIC OR MANUAL) IS USED.

SPECIFICATIONS

ELECTRICAL

T

RANSFORMER:

.............24VAC

CONTROL STATION:

......NEMA 1 three button station.

OPEN/CLOSE/STOP

WIRING TYPE:

MGJ:

B2-C2 (Factory Shipped)

LGJ:

G2 (Factory Shipped)

See pages 13 and 14 for optional control settings and

operating modes.

LIMIT ADJUST:

................Linear driven, fully adjustable

screw type cams. Adjustable to 24 feet.

7.50”

7.00”

11.00”

9.25”

LGJ WEIGHTS AND DIMENSIONS

HANGING WEIGHT:

..........

80-110 LBS.

10.50”

11.05”

MOUNTING DIMENSIONS

3.00”

5.50”

4.75”

8.90”

7.90”

1.97”

10.88”

4.50”

2.25”

.98”

1.96”

MOUNTING DIMENSIONS

MGJ WEIGHTS AND DIMENSIONS

HANGING WEIGHT:

..........

80-110 LBS.

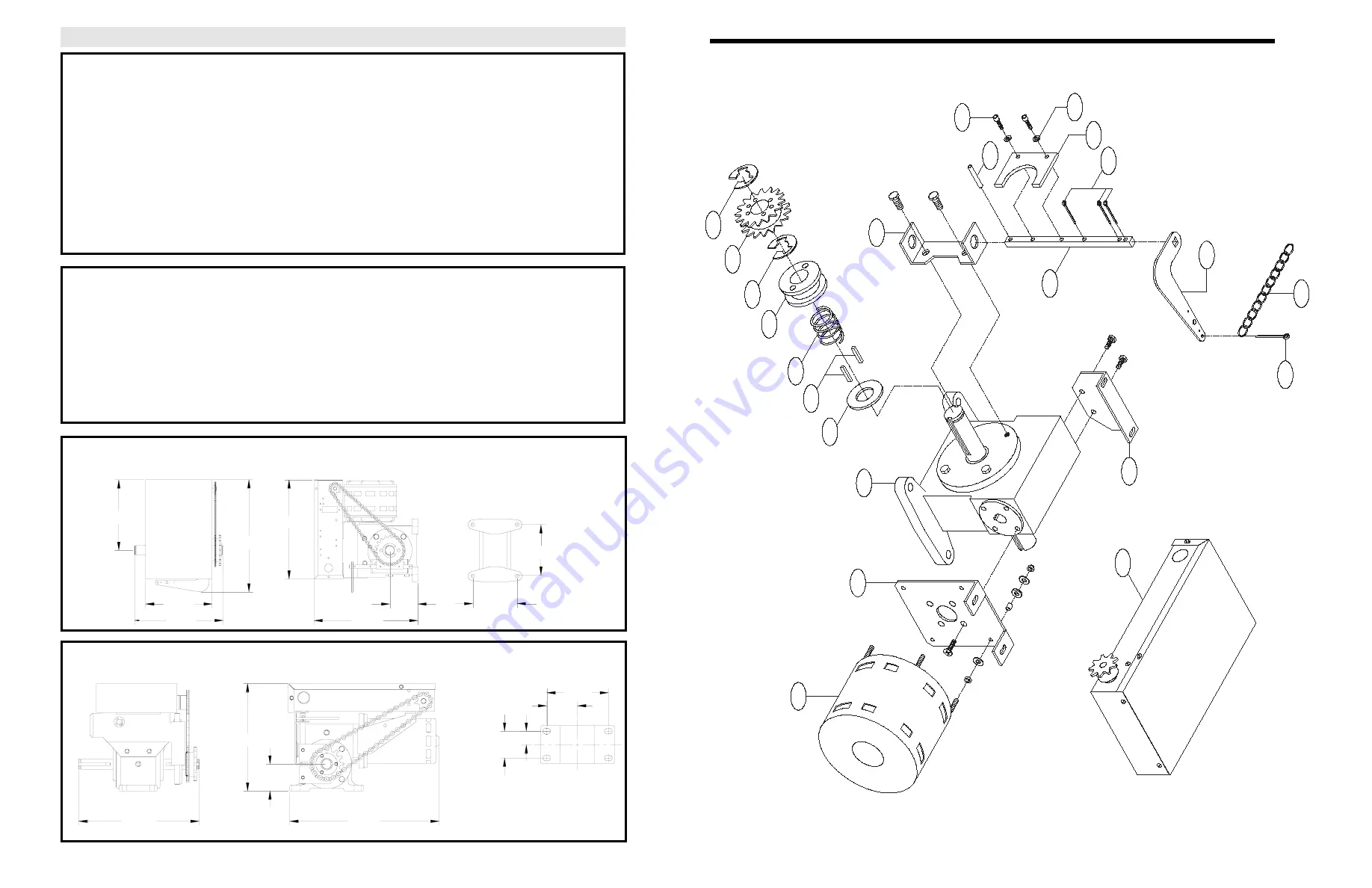

23

ILLUSTRATED PARTS – MODEL

MGJ

D8

D13

4

5

1

3

D10

D9

D7

D1

D15

D6

D15

D3

D4

D5

D13

D2

D12

D14

D1

1

2