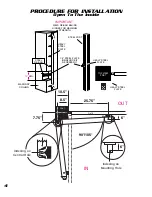

Procedure For Installation

(cont.)

7

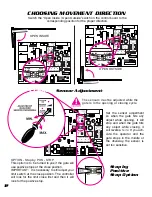

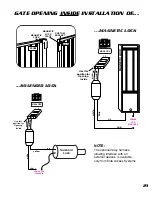

CORRECT

CORRECT

WRONG

P L A C E M E N T O F M I R A C L E • 1 O N G A T E

For strength purposes, the front bracket must be welded in an area that can withstand heavy

forces. Do not weld a cross bar on just a few pickets or the pickets will bend. Weld a cross bar

across all of the pickets or weld the front bracket at the top of the gate directly to the frame.

ACCESS SYSTEMS INC

™

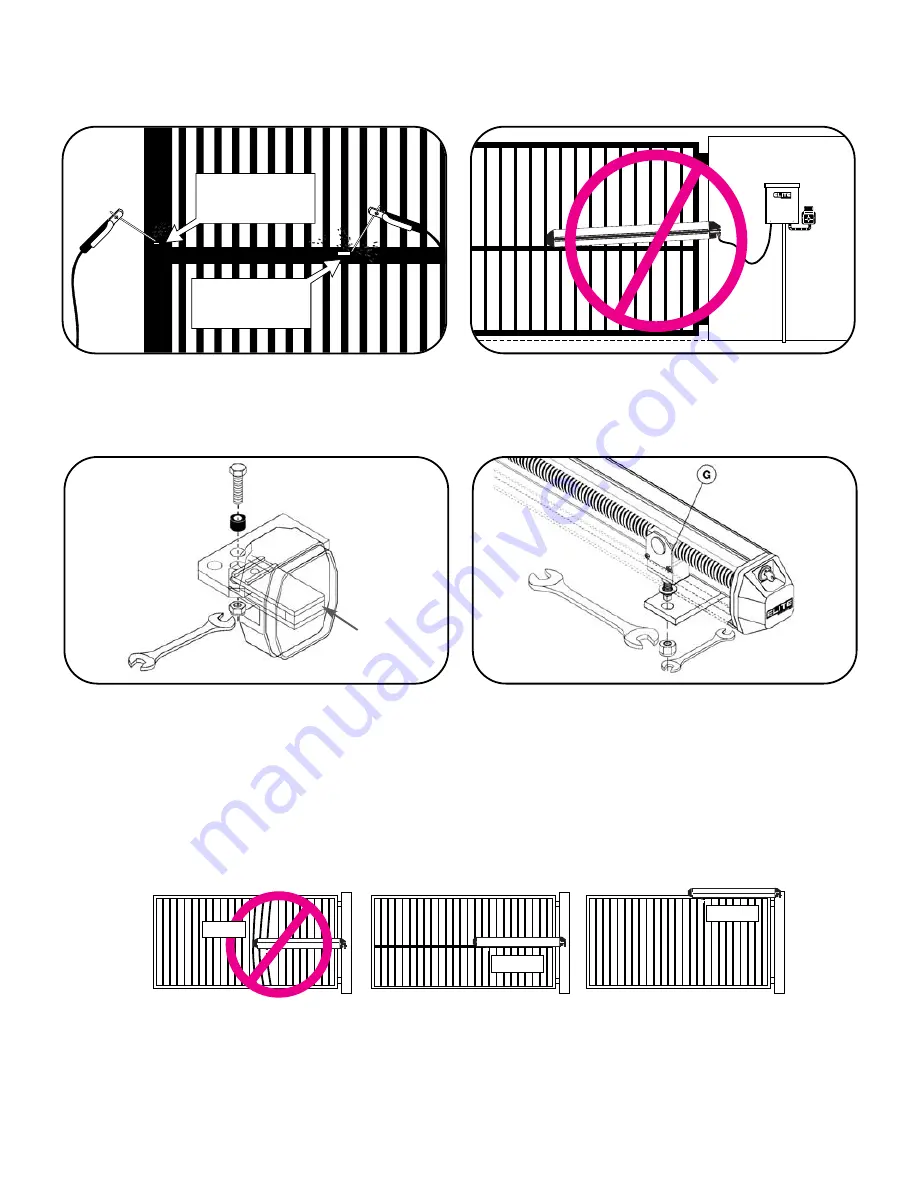

STEP 5: MAKE SURE THE OPERATOR IS LEVEL

OR THE OPERATOR WILL NOT FUNCTION PROP-

ERLY. AN OFF-LEVEL INSTALLATION MAY CAUSE

THE GATE OR OPERATOR TO FAIL PREMATURELY.

FULLY WELD

BRACKET AND

PLATE

FULLY WELD

BRACKET IN

POSITION

STEP 4:

REMOVE OPERATOR AND FULLY WELD

THE PLATE AND BRACKETS TOP, BOTTOM AND

SIDES.

CAUTION: WELDING WITH OPERATOR IN

PLACE MAY DAMAGE THE OPERATOR.

STEP 7:

REMOVE NUT FROM BOLT ON FRONT

OF OPERATOR. FIT THE GROUP - G - TO THE

GATE. MANUALLY MOVE THE GATE OPEN AND

CLOSE. CHECK FOR SMOOTH AND UNOB-

STRUCTED MOVEMENT. FULLY TIGHTEN THE

NUT.

STEP 6:

REMOVE BOLT AND BUSHING FROM

BACK OF OPERATOR. FIT THE OPERATOR TO

THE PIER USING THE HOLE WHICH IS THE MOST

SUITED TO THE OPENING DIMENSIONS

REQUIRED.

a.

Place metal bushing into the bracket hole you will

be using.

b.

Fit operator bracket over hole with metal bushing.

c.

Use bolt and nut to secure operator to bracket.

c.

a.

b.